Backwash self-cleaning ventilation device

A ventilation device, self-cleaning technology, applied in ventilation system, space heating and ventilation, space heating and ventilation details, etc., can solve the problems of large manpower and material resources, time-consuming and laborious, troublesome

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

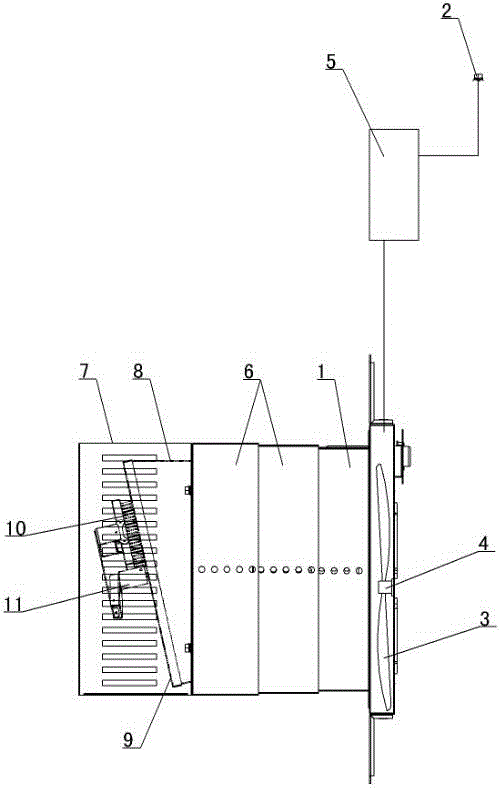

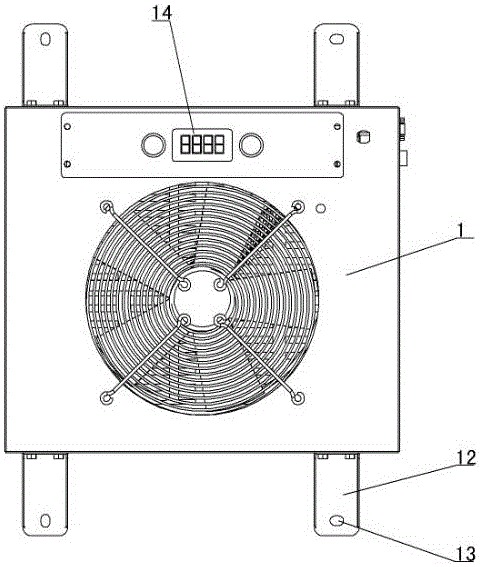

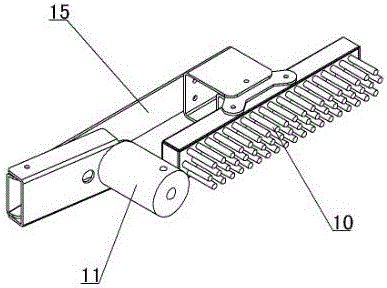

[0011] The invention relates to a backwash self-cleaning ventilation device, such as figure 1 — Figure 4 As shown, it includes a fresh air host installed indoors and a filter box installed outdoors. The filter box and the fresh air host are connected as a whole through a connection module. The indoor fresh air host includes a mesh cover shell 1 and a temperature probe 2 The fan blade 3 and the fan blade motor 4 are installed in the net cover housing, the fan blade motor 4 and the temperature probe 2 are connected to the control system 5, the connection module is a flange connector 6, and the outdoor filter box includes a protective net Cover box 7, filter screen support 8 is installed in the protective net cover box 7, filter screen 9 is installed on the filter screen support 8, cleaning hairbrush 10 and hairbrush motor 11 are installed in the protective net cover box 7, cleaning hairbrush 10 and filter screen 9-phase contact, the brush motor 11 is connected to the control s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com