Loader discharge angle detection device and its detection method

A detection device and unloading angle technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of time-consuming and laborious, safety risks, and hidden dangers of misreading by workers, so as to reduce safety risks, eliminate hidden dangers, and eliminate misreadings. the effect of hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

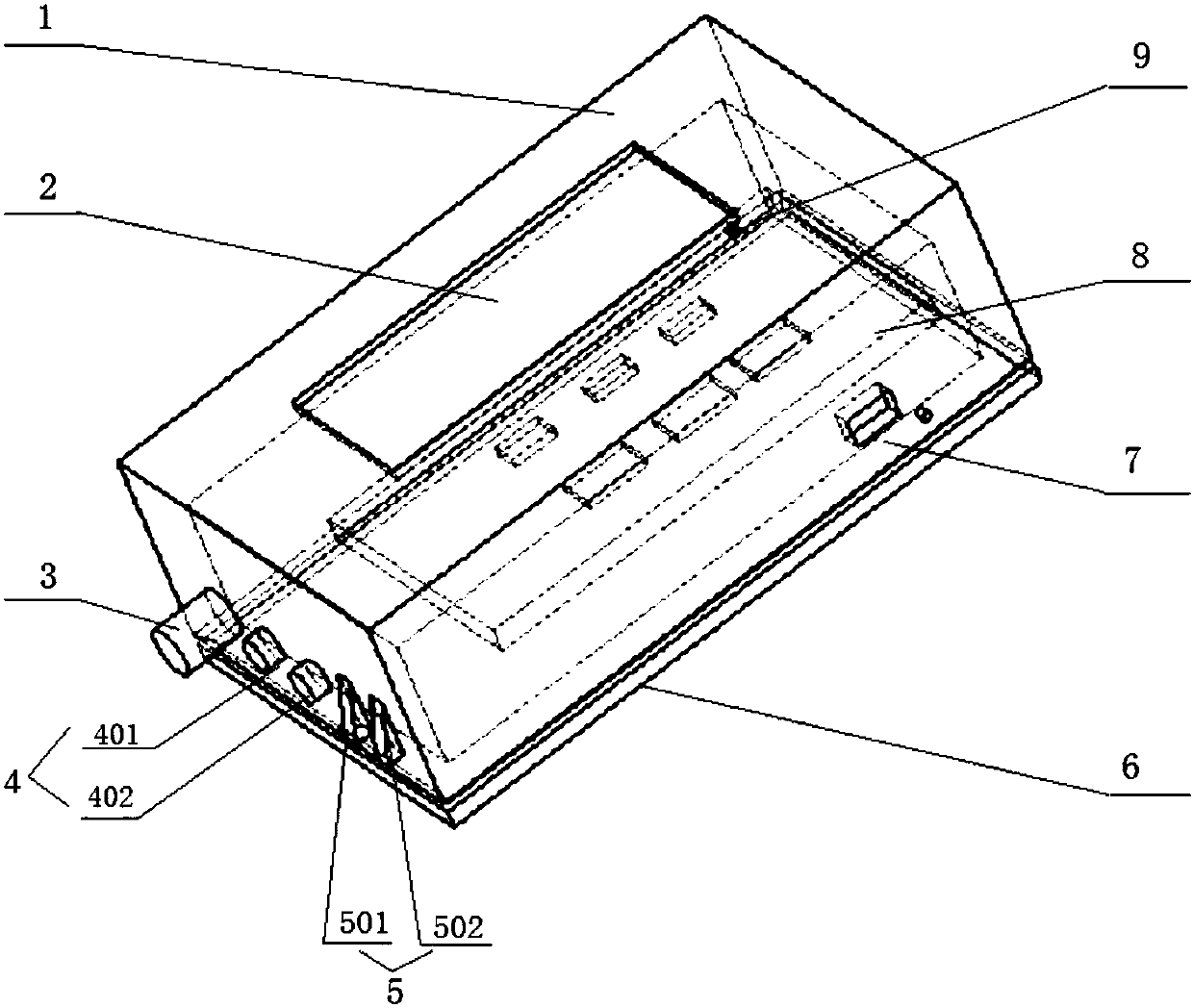

[0054] A loader discharge angle detection device, comprising a housing 1, a display screen 2, a power button 5, a magnetic chuck base 6, a USB charging interface 7, a functional circuit 8, and an indicator light 9;

[0055] The shell 1 is a metal waterproof shell, the display screen 2 is an OLED display screen, the power button 5 includes a main power switch button 501 and a working mode selection button 502, and the indicator light 9 is an LED indicator light.

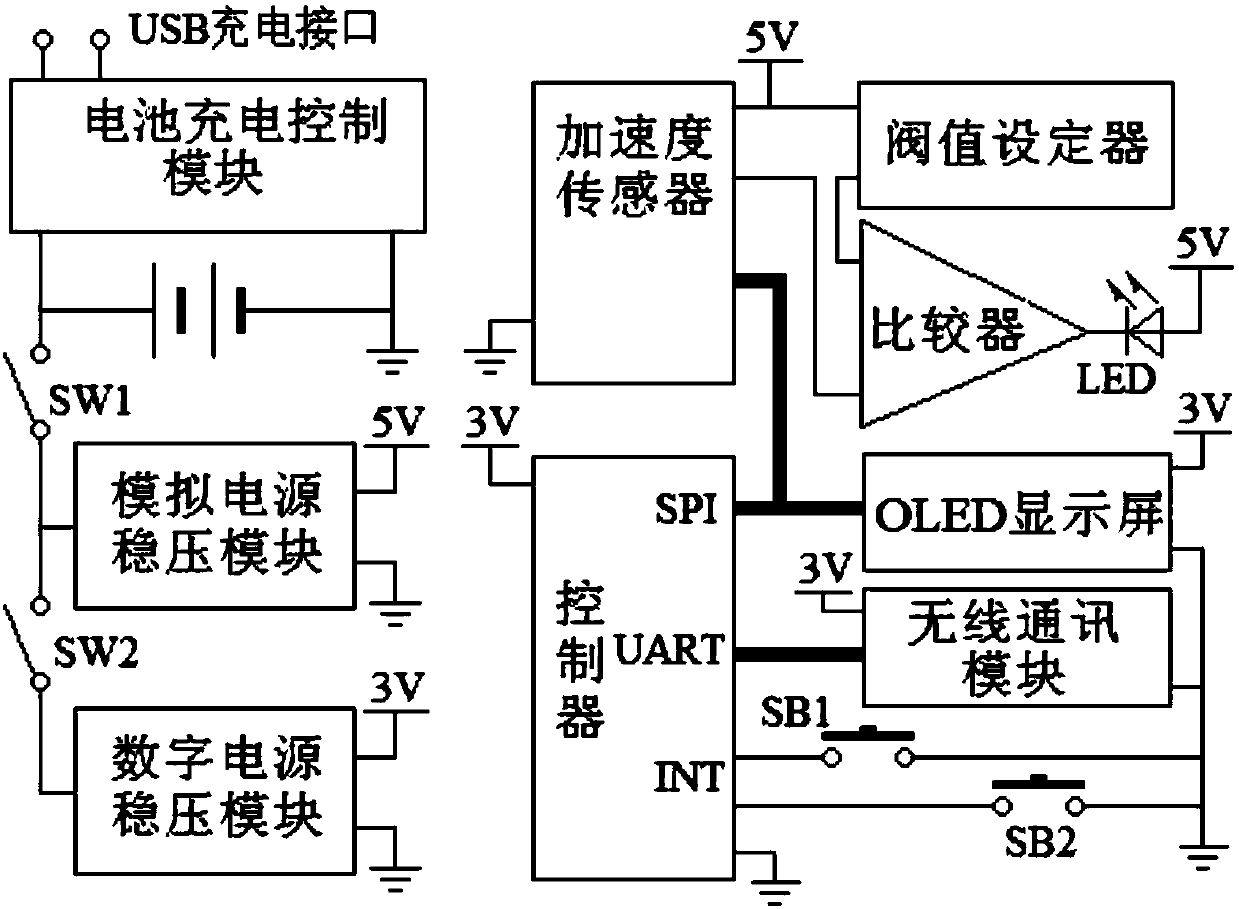

[0056] The above-mentioned power button 5, USB charging interface 7, and indicator light 9 are respectively arranged on the casing 1, the functional circuit 8 is arranged inside the casing 1, and the magnetic chuck base 6 is connected to the bottom of the casing 1, and the magnetic chuck base 6 is installed on the loading The bottom surface of the machine bucket; the functional circuit 8 includes a power supply module, a discharge angle measurement module, a power-saving processing module, and a general processing modu...

Embodiment 2

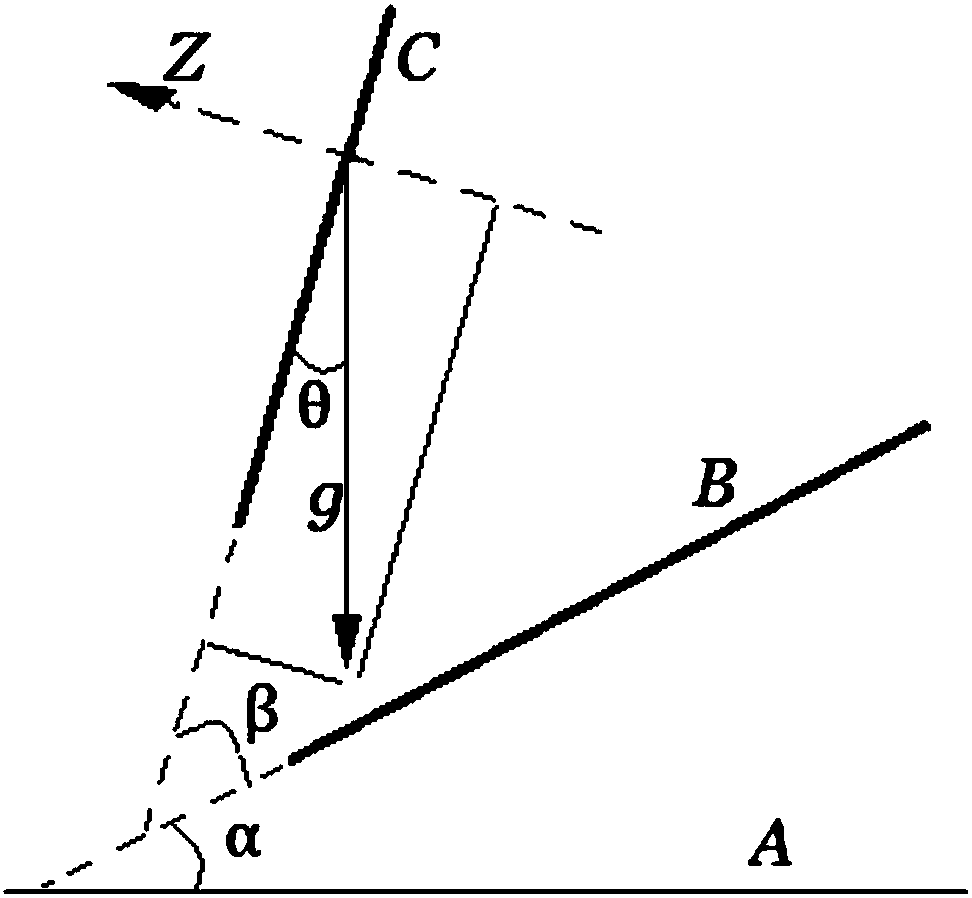

[0063] A loader discharge angle detection method, the method is realized based on the loader discharge angle detection device described in Embodiment 1, the method includes the following steps:

[0064] S1. Start up:

[0065] Press the main power switch button, the ship switch SW1 is powered on and started, and observe the display screen to confirm that the loader unloading angle detection device is working normally;

[0066] S2. Install the loader discharge angle detection device:

[0067] When the loader bucket falls to the loading position, the loader discharge angle detection device is adsorbed to the bottom surface of the bucket through the magnetic suction cup base, and the placement angle of the loader discharge angle detection device is adjusted to align with the weld seam on the bottom surface of the bucket;

[0068] S3. Select the working mode for detection:

[0069] Press the working mode selection button to select the working mode for detection. When the power-sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com