Multifunctional true triaxial rock drilling test system and test method for characterizing the characteristics of rocks

A testing system, true triaxial technology, applied in soil material testing, strength properties, testing material strength using stable tension/pressure, etc., can solve the problem of hard rock and soil layers that cannot consider the influence of three-dimensional stress on the drilling process. Difficult to drill, single factors affecting drilling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

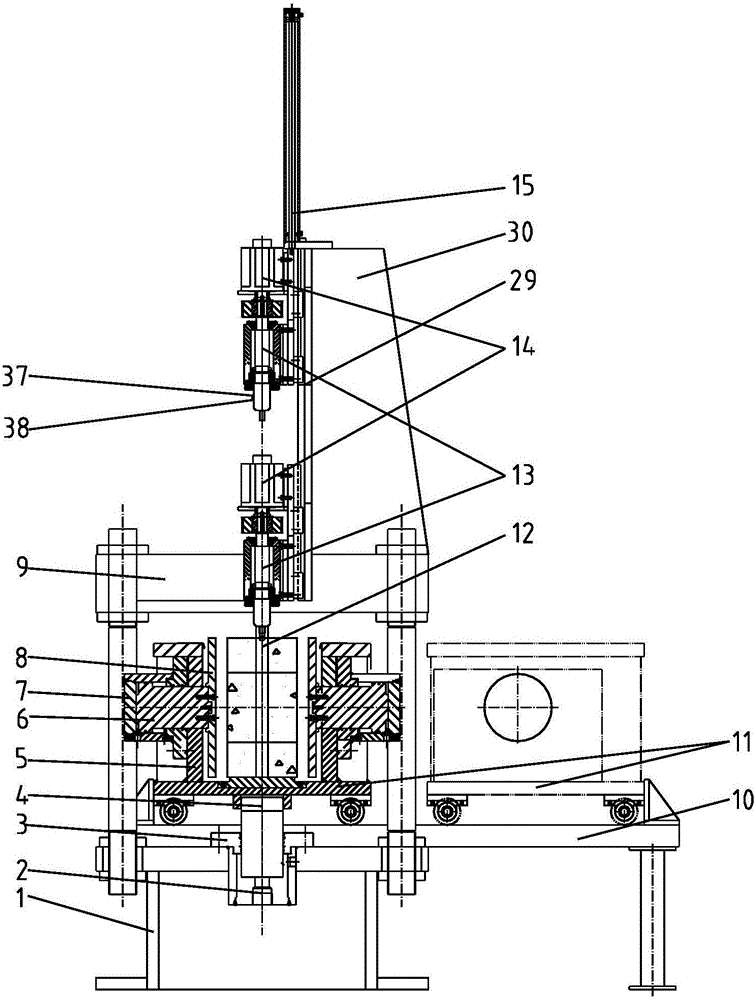

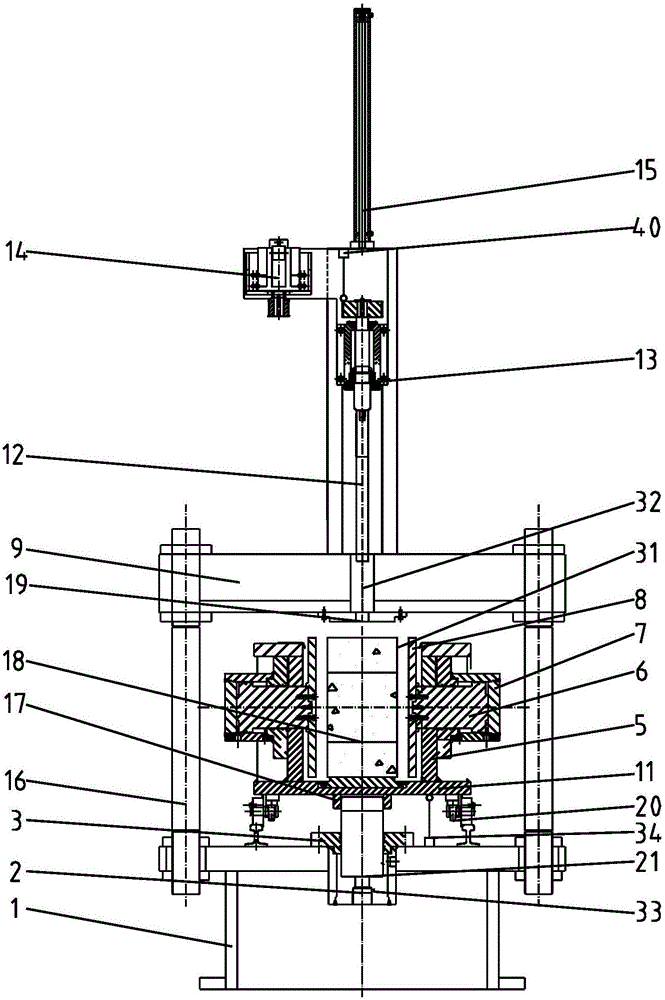

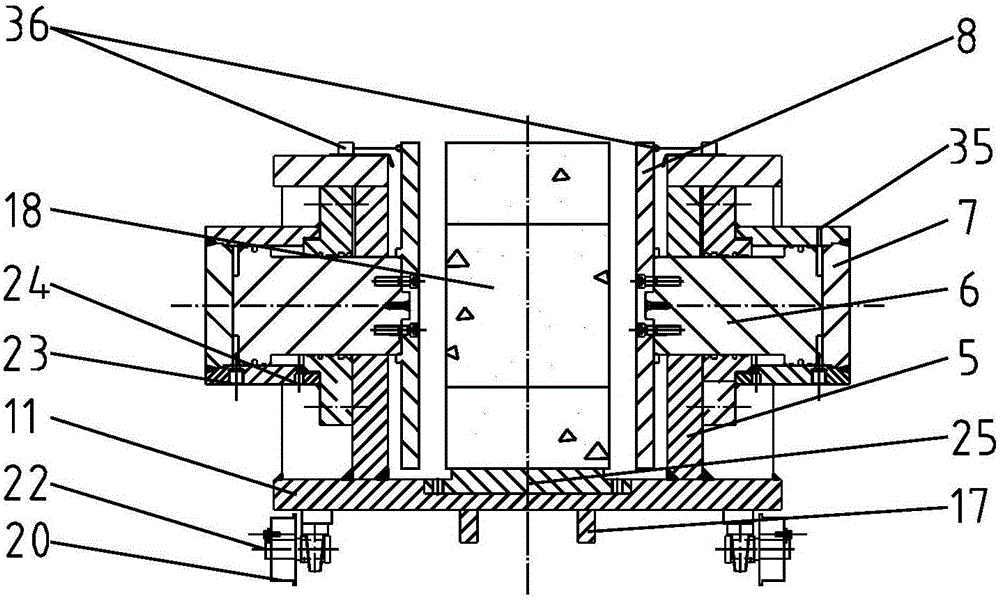

[0133] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0134] The true triaxial rock drilling tester includes a support frame with a reaction frame on the top, a test piece platform 11 for placing the test piece is set in the support frame, and a surrounding rock loading device is set around the test piece platform 11. The bottom of the piece platform 11 is provided with an axial pressure loading device that can contact the upper part of the test piece with the reaction force frame, and a liftable and rotatable drill 13 is set on the top of the reaction force frame 9. The drilling tester also includes a test piece for measuring A sensor for drilling parameters and a monitoring control system connected with the sensor.

[0135] The sensors include an axial displacement sensor 34 located at the bottom of the test piece platform, a dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com