Devices for rotary stamping

A technology for adjusting devices and rollers, which is applied in the direction of rotary printing machines, printing machines, printing machines, etc., and can solve problems such as strong vibrations, gap size changes, and stability limitations of stamping devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Individual technical features of the embodiments described below can likewise be combined in combination with the previously described embodiments as well as features of the dependent claims and possible further claims relative to the object according to the invention.

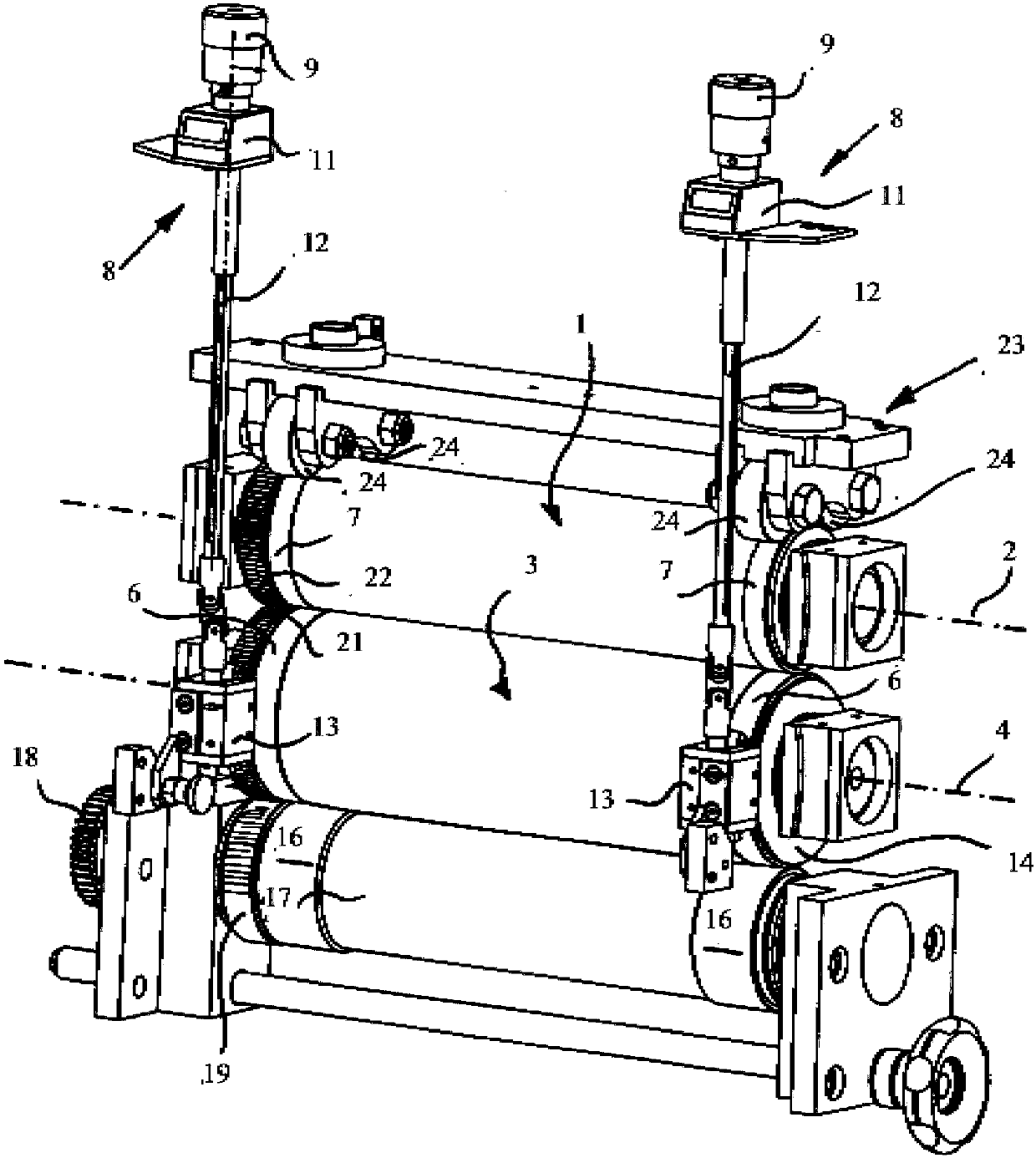

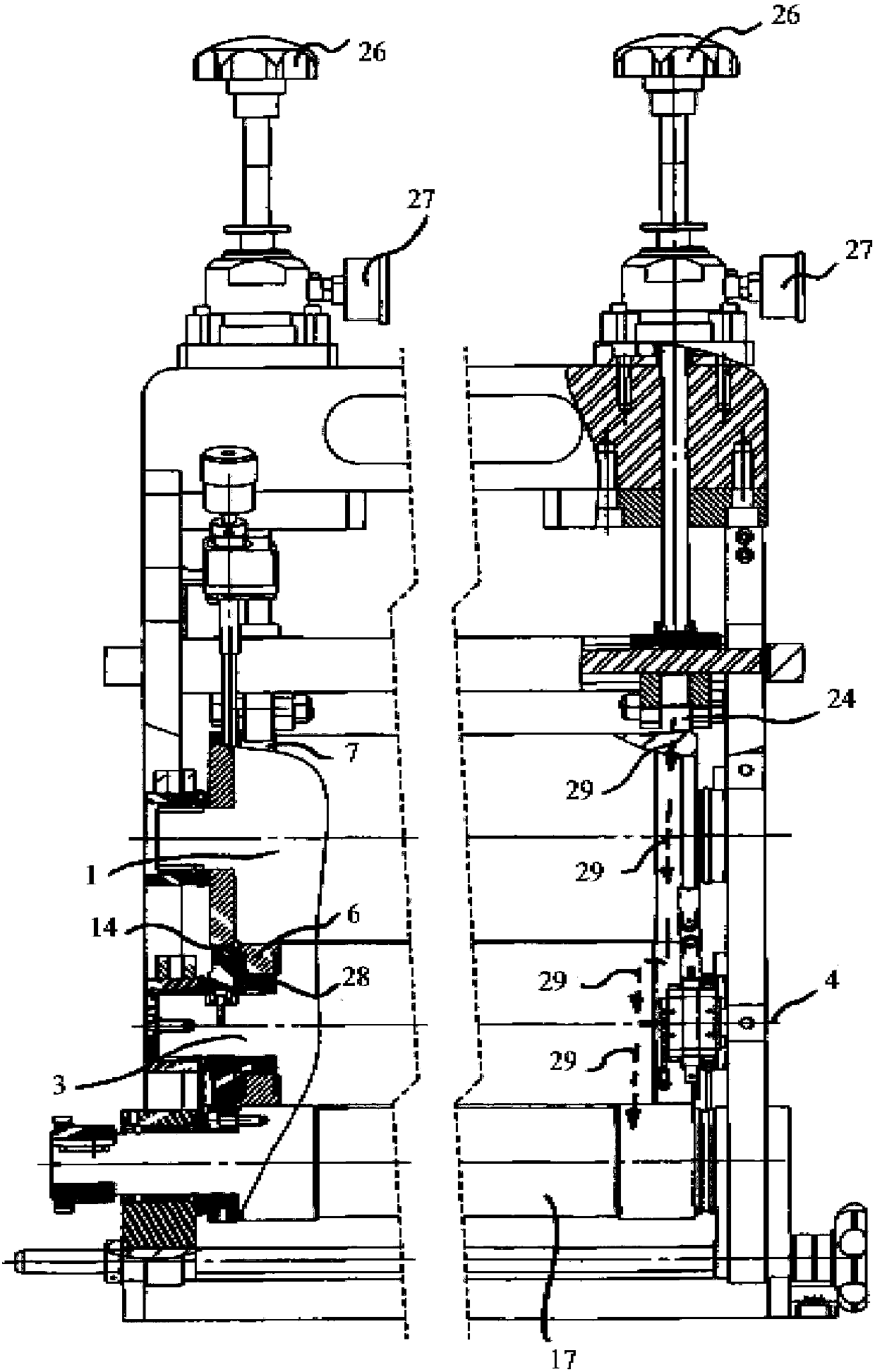

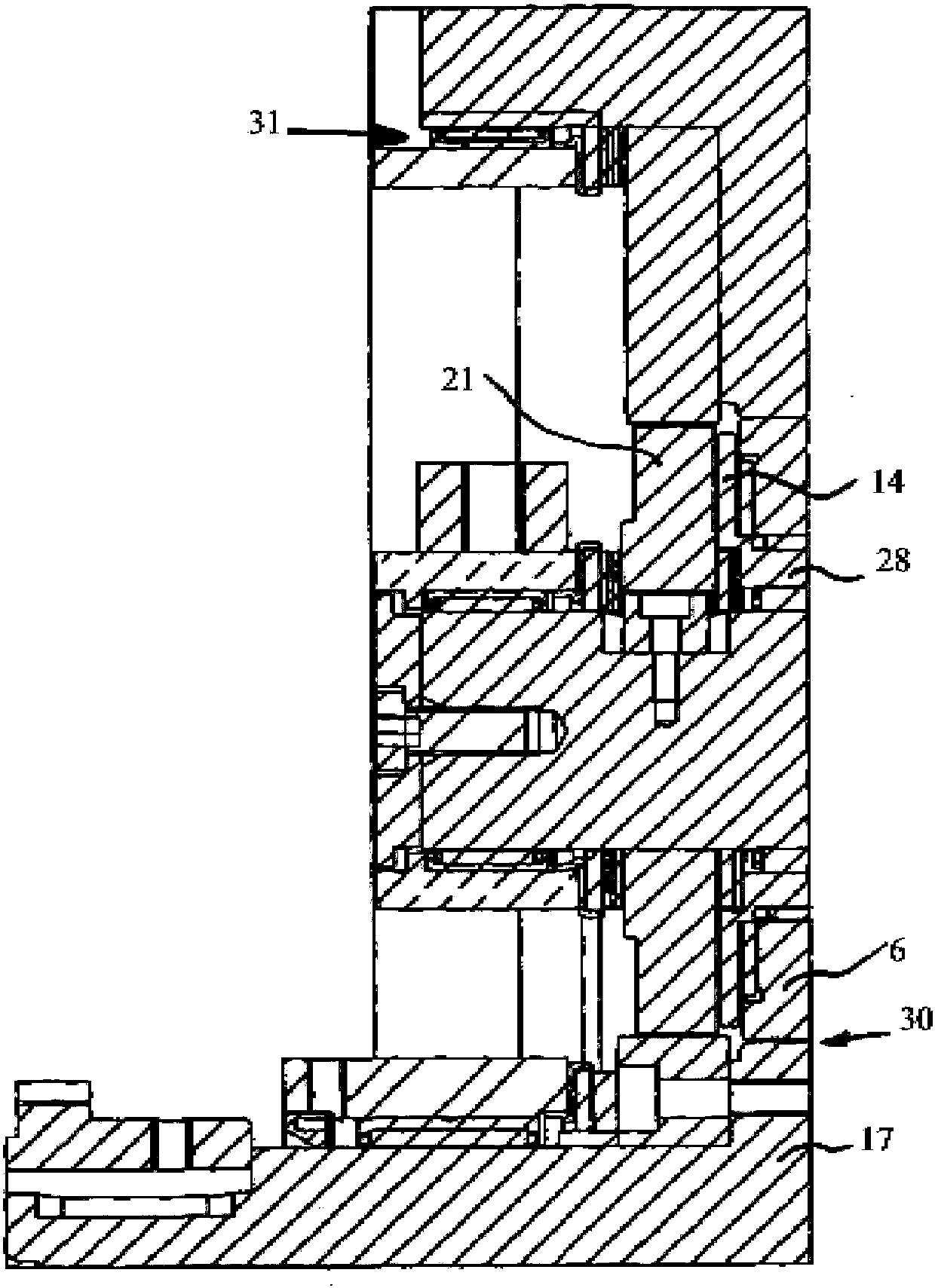

[0025] The device according to the invention for rotary stamping according to figure 1 A stamping cylinder 1 is provided which is arranged rotatably about a stamping cylinder axis 2 . Furthermore, the device has a counterpressure roller 3 which is rotatable about a counterpressure roller axis 4 . The counter-pressure cylinder 3 has a running ring 6 on which the running surface 7 of the punching cylinder 1 runs. These running surfaces 7 can be part of a separately produced stamping cylinder raceway or can be formed in one piece with the stamping cylinder body. Furthermore, the rotary punching device has an adjusting device, by means of which the size of the gap between the punching cylinder 1 and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com