Incubation workshop automatic egg traying device

An automatic and tray-setting technology, applied in the application, poultry industry, animal husbandry and other directions, can solve the problems of high labor intensity and low work efficiency, and achieve the effect of improving work efficiency, simple structure and ensuring survival rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

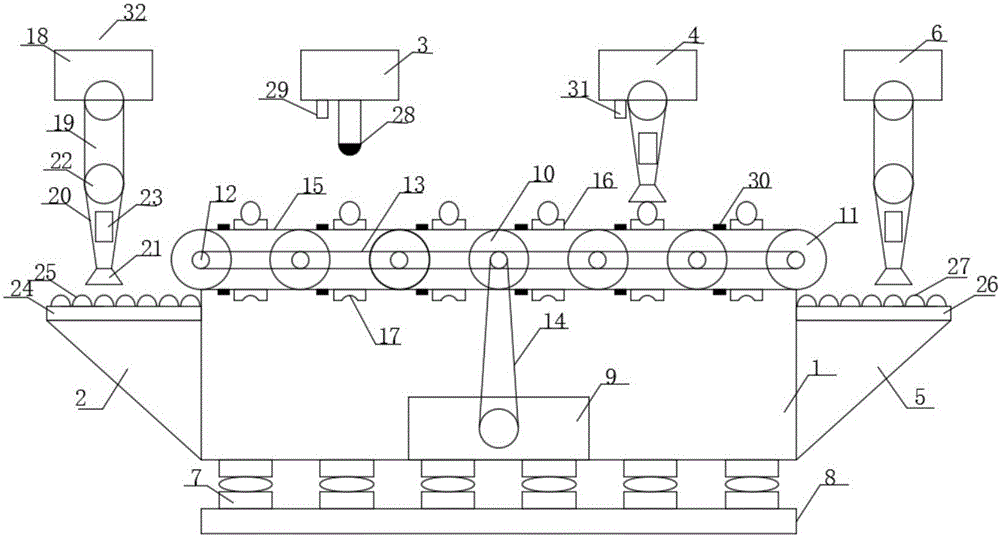

[0019] The invention provides an automatic plate placing device in a hatching workshop, which has a simple structure and is easy to use, and can automatically complete the operations of transportation, egg picking, selection of problem eggs, and plate placing, which saves manpower and improves work efficiency. The positioning of the hatcher is accurate, and the quality of the work is high. At the same time, it is equipped with a shock absorber to ensure the survival rate of the eggs.

[0020] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

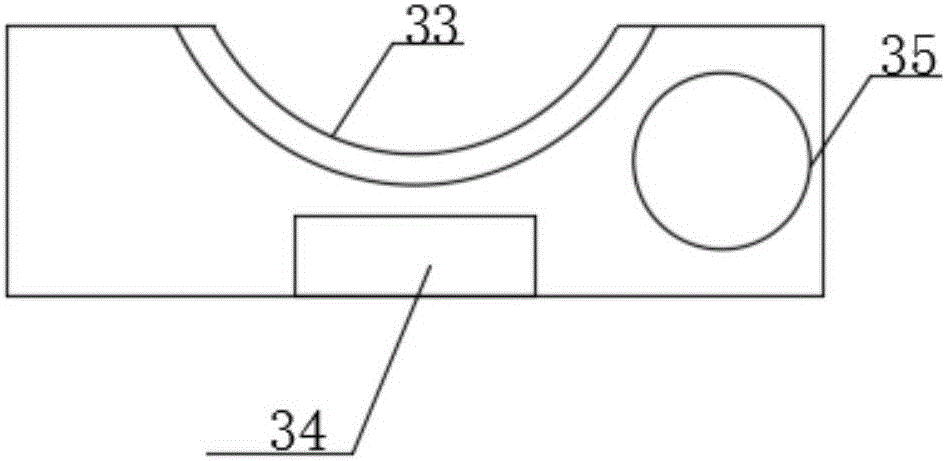

[0021] like Figure 1-Figure 2 As shown, an automatic plate placing device for a hatching workshop described in this embodiment includes a frame 1, a conveying device, a left end support frame 2, an original egg suction device 32, an egg candling device 3, a bad eg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com