Slag absorber

A controller and framework technology, applied in the direction of chemical instruments and methods, baking, dough forming machinery or equipment, etc., can solve the problems of wasting manpower, wasting resources, increasing costs, etc., and achieve manual cleaning, manual operation, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

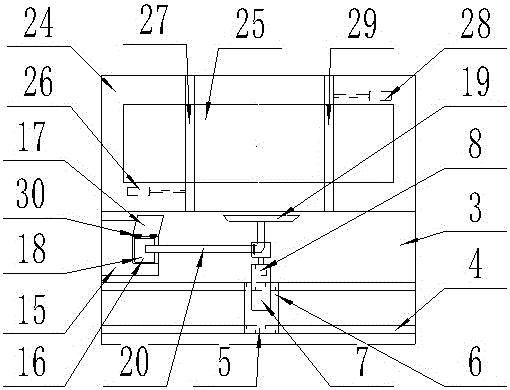

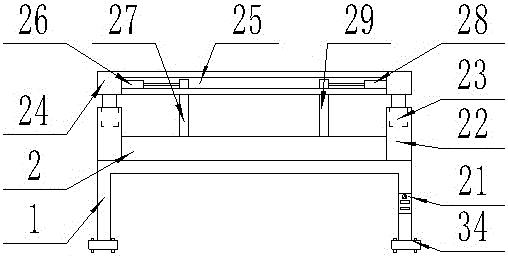

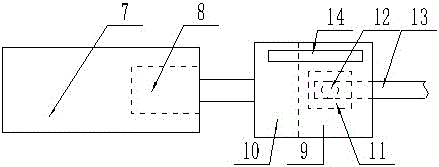

[0017] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 As shown, a slag suction device includes a rectangular body frame (1), the bottom end of the rectangular body frame (1) is fixedly installed on the ground, and the rectangular body frame (1) is fixedly installed with a rectangular Working board (2), an adjustable cutting device is provided above the working board (2), and a slag suction device is provided on one side of the working board (2), and the slag suction device is fixedly connected to the frame by the side surface (1) The mounting plate (3) on one side, a set of parallel chute (4) on the surface of the mounting plate (3), and the double-track electric motor with pulleys (5) on both sides embedded in the parallel chute (4) The trolley (6), the installation arm (7) fixedly connected to the upper surface of the double-track electric trolley (6) and placed horizontally, the linear motor (8) fixedly install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com