Low noise soya-bean milk making method for soya-bean milk machine

A soybean milk machine, low-noise technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problem of high noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

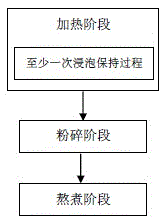

Method used

Image

Examples

Embodiment Construction

[0034] This embodiment takes the way that the motor of the soymilk machine is placed on top as an example. The soymilk machine includes a machine head and a cup body. The machine head is provided with a motor and a motor shaft, wherein the motor is placed in the cup body and the motor shaft is arranged at the lower end of the motor. In addition, a crushing tool is provided at the lower end of the motor shaft, and the motor drives the crushing tool to work, and a heating device is provided outside the cup body. In addition, the rated heating power of the soybean milk machine is 1000W, the rated speed is 20000r / min, and the maximum water capacity of the body is 1.5L.

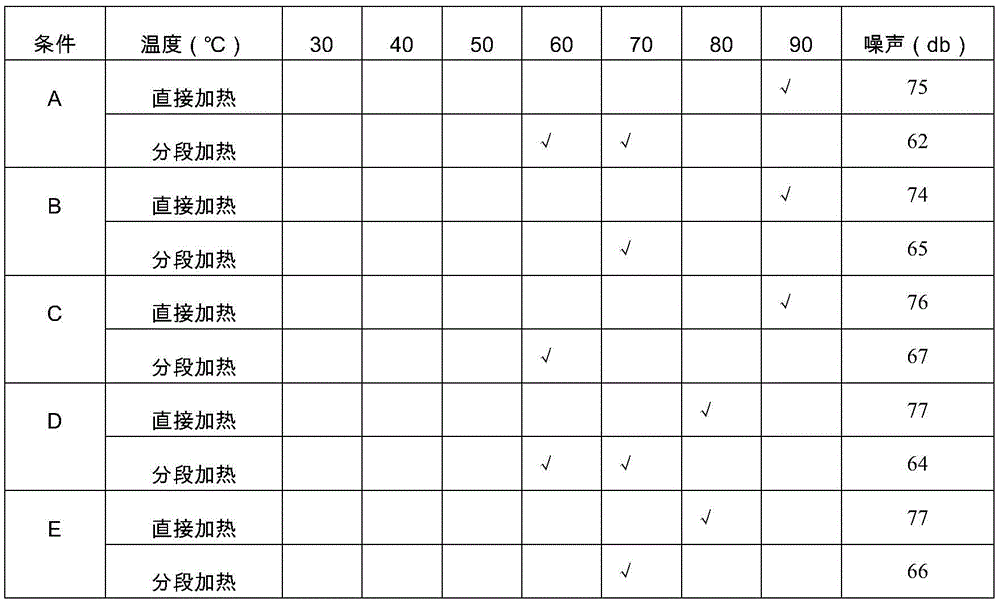

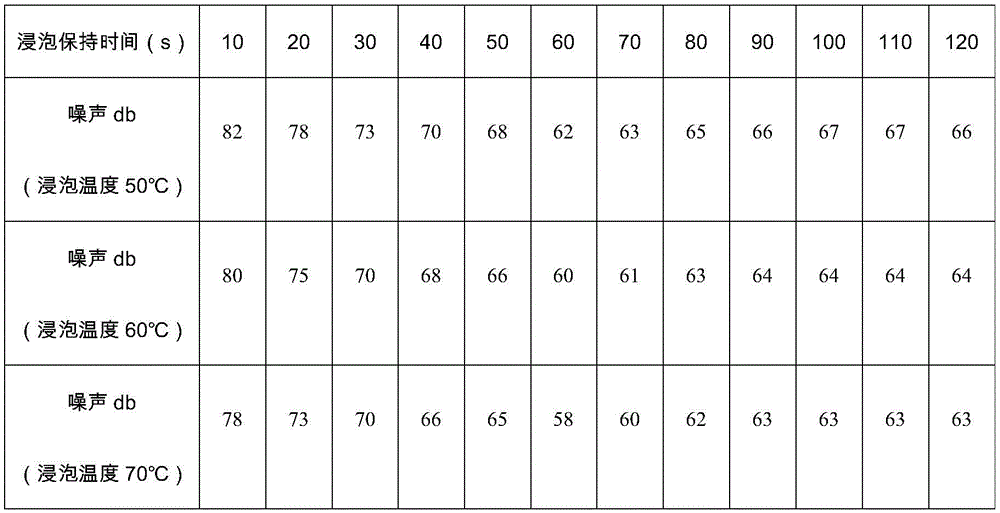

[0035]It is well known that temperature plays a decisive role in the change of materials such as soybeans. In particular, different temperatures have different effects on the softening, expansion, and release of nutrients such as protein in materials such as soybeans. Correspondingly, soybeans, etc. The water abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com