Powder aerosol generator for preventing low-fluidity drug from caking

An aerosol generator, low-fluidity technology, applied in aerosol preparation, colloid chemistry, colloid chemistry, etc., can solve the problems of upright accumulation and agglomeration, huge difference in fluidity, affecting the quantitative control of aerosol generators, etc. To achieve the effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

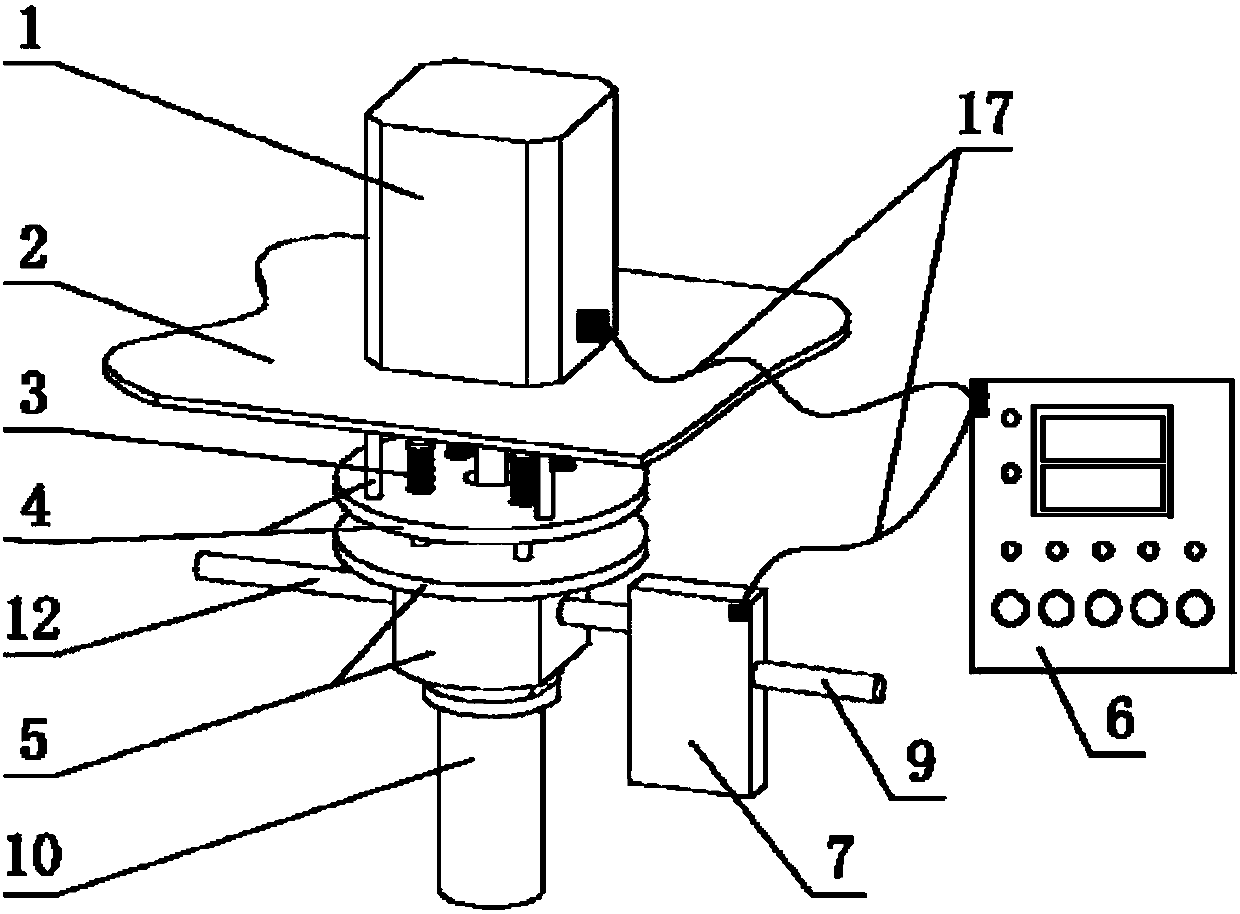

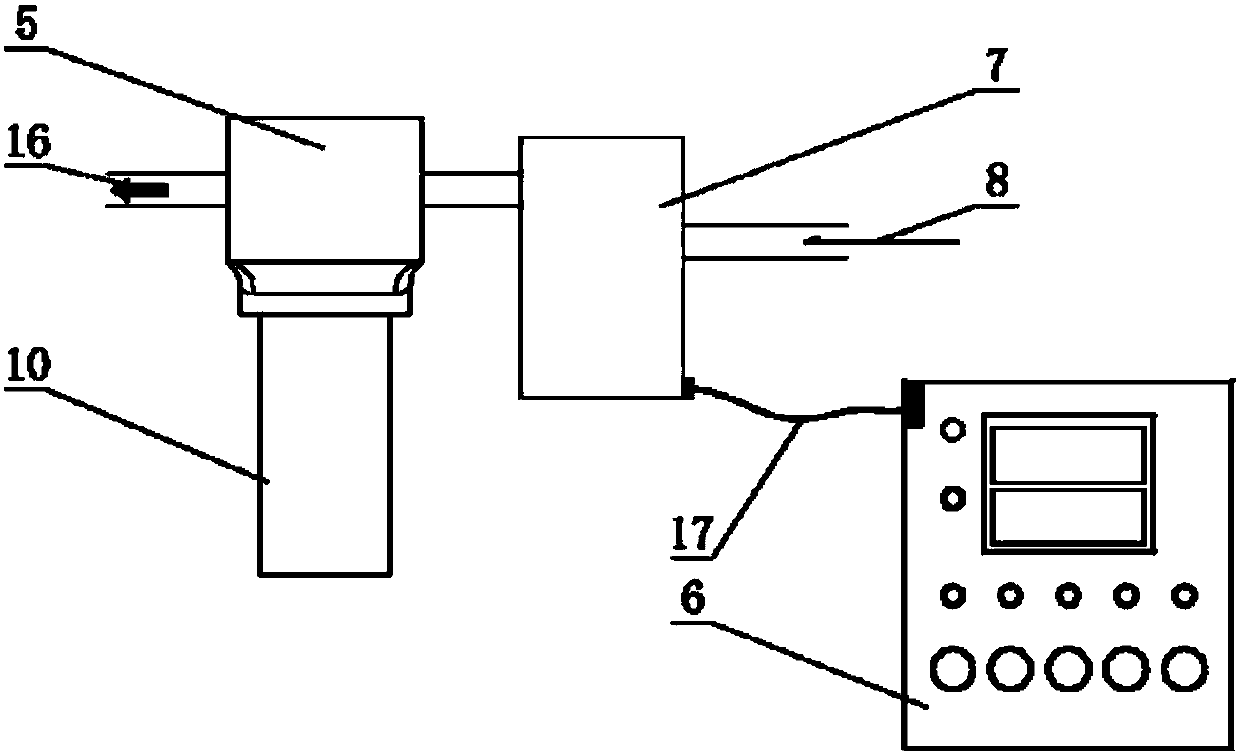

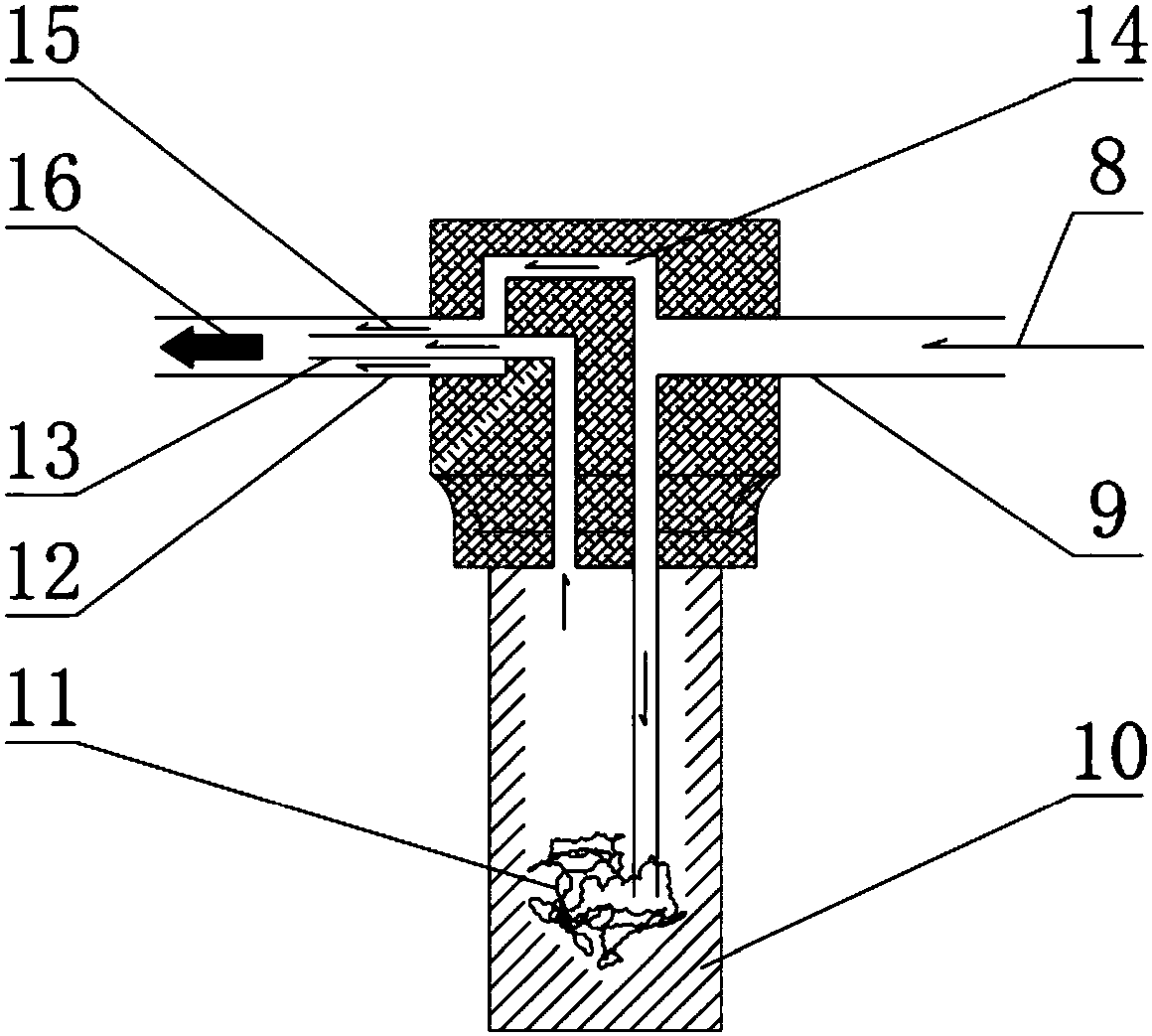

[0017] The following will be combined with Figure 1-3 The technical solution of the present invention is described in detail.

[0018] Such as Figures 1 to 3 As shown, a powder aerosol generator for preventing agglomeration of low-fluidity medicines includes a vibrating device, a diffuser and a controller 6 .

[0019] Among them, the function of the rapping device is to disintegrate the vertical accumulation and agglomeration of the powder by rapping, so as to ensure the quantitative control of the diffuser and expand the scope of application of the diffuser. It is mainly composed of electromagnet 1, cover plate 2, reset Spring 3, support 4 constitutes. The cover plate 2 is the top plate of the entire drug exposure cabinet. The electromagnet 1 is fixed on the cover plate 2 by screws; the bracket 4 is fixed on the cover plate 2 by its four threaded rods, and the vibration axis on the electromagnet 1 passes through the cover plate. The round hole in the center of the plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com