Stirring paddle

A stirring paddle and stirring shaft technology, applied in the field of stirring paddles, can solve the problems of laborious mixing of cement, increasing the mass and volume of the stirring paddle, and insufficiently uniform stirring of the cement, and achieving convenient connection, increased stirring effect, and easy installation, disassembly and cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand the content of the present invention, the present invention is described in detail in conjunction with examples, and the following examples are used to illustrate the present invention, but are not used to limit the scope of the present invention.

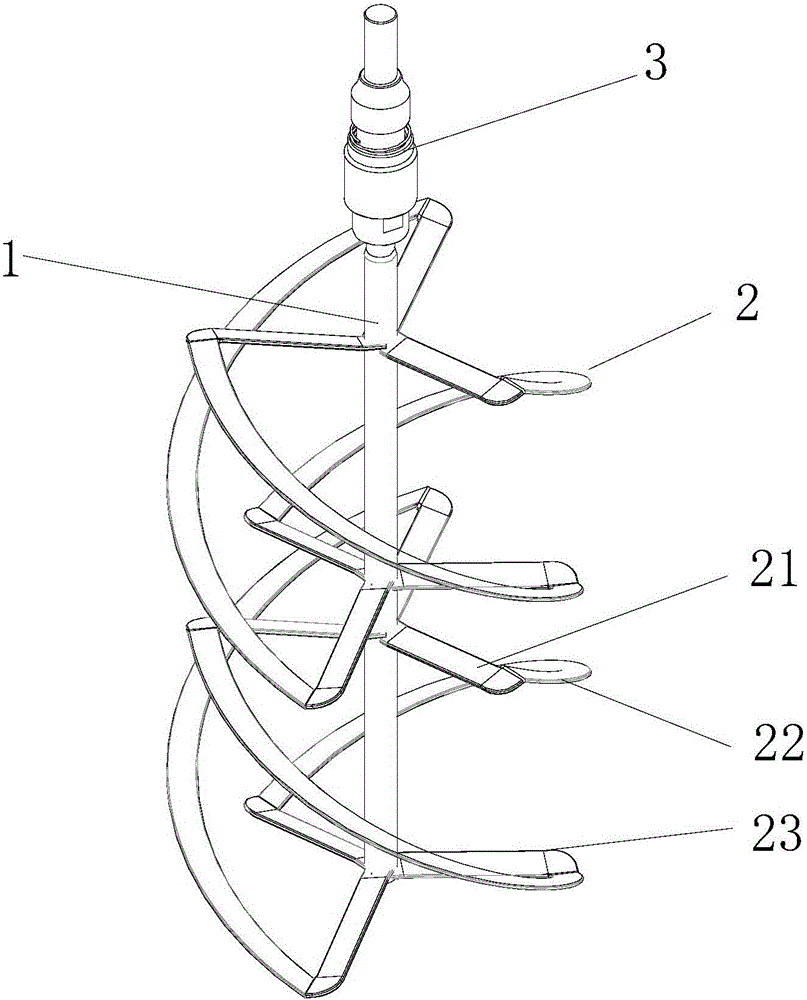

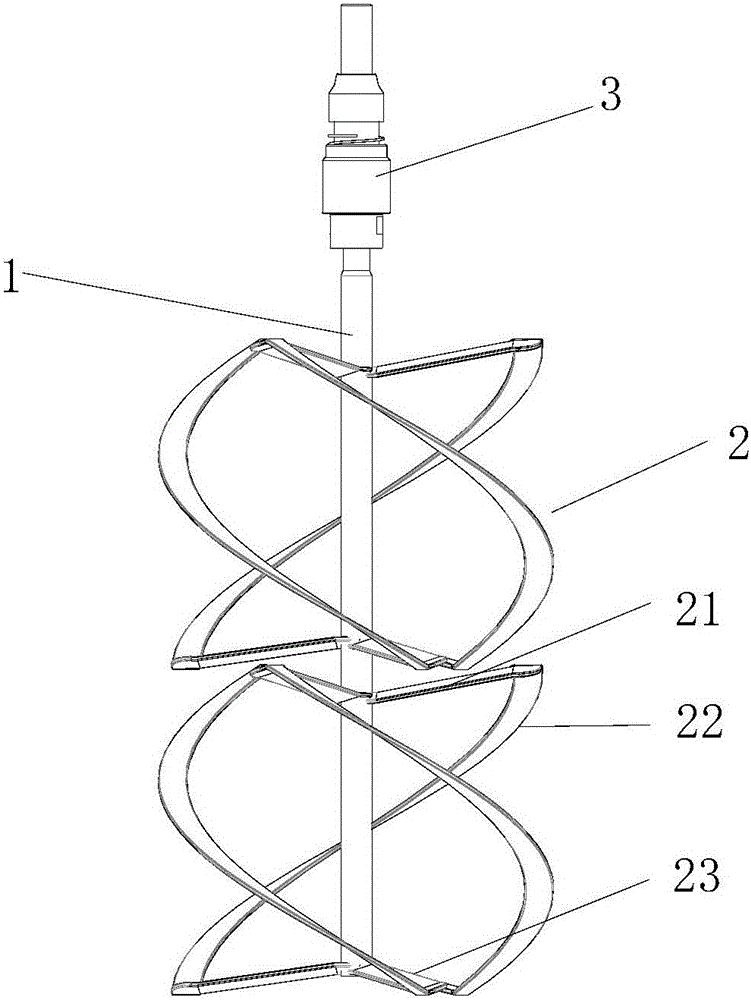

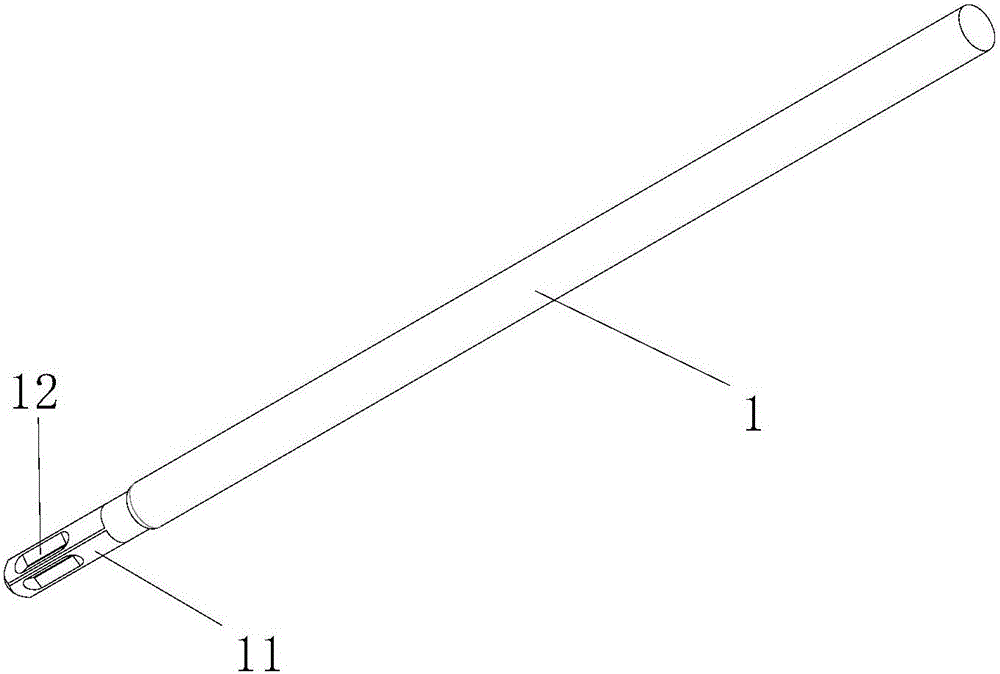

[0025] refer to figure 1 and figure 2 A stirring paddle in this embodiment includes a stirring shaft 1 , a paddle 2 and a connecting part 3 , the paddle 2 is welded to the stirring shaft 1 , and the connecting part 3 is arranged at the top of the stirring shaft 1 .

[0026] In the present embodiment, the blades 2 are two layers, and each layer of blades 2 is provided with three blades. The height of the blades is 152 mm, the maximum radius of the blades is 72 mm, and the width of the blades is 36 mm. The surface of the blades must not have scratches. refer to Figure 5 , the blades include an upper inner swirl plate 21, a lower inner swirl plate 23 and an outer swirl plate 22, one end of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com