Automatic color changing machine of 3D printer

A 3D printer and automatic technology, applied in the field of 3D printing, can solve the problems of breaking the color material, the structure is not stable enough, and the operation is troublesome, so as to achieve the effect of preventing the color material from breaking, the use effect is good, and the transmission is stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

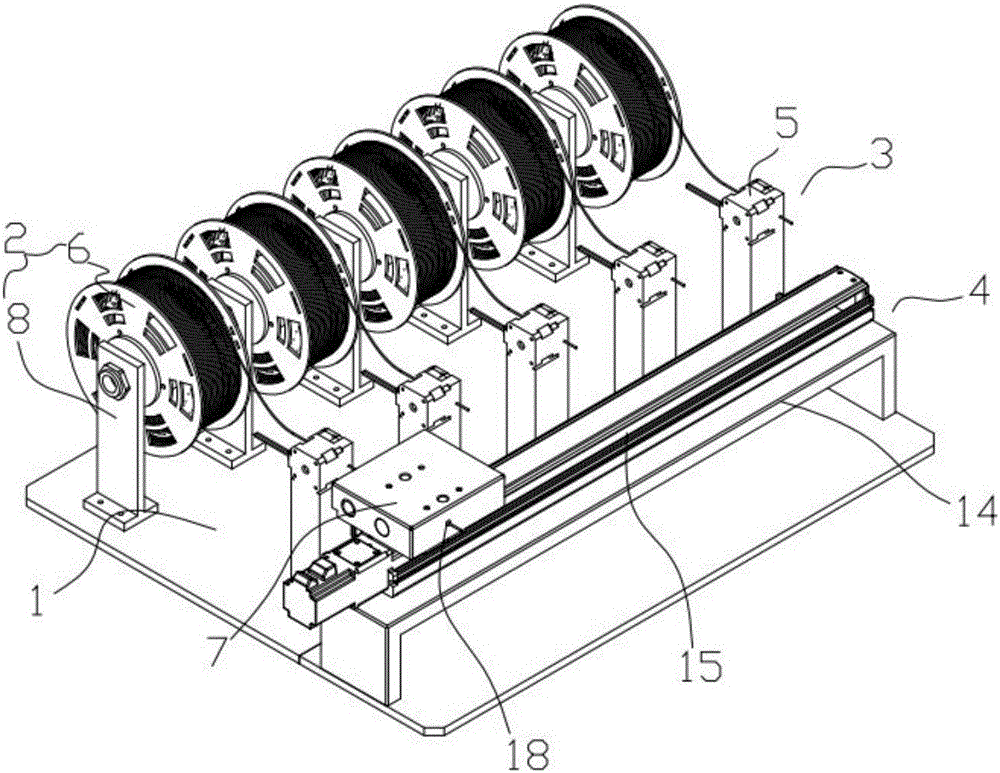

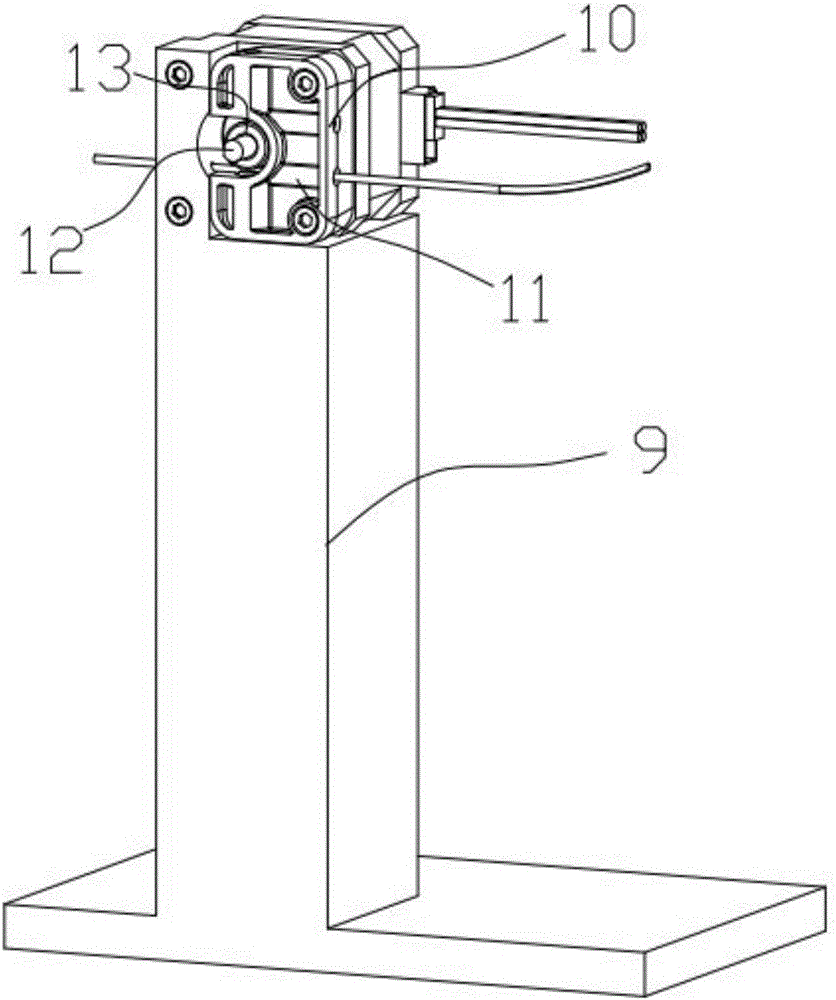

[0022] like figure 1 , figure 2 , The present invention proposes an automatic color changing machine for 3D printers, including a base plate 1, on which a loading device 2, a feeding mechanism 3, and a servo module 4 are arranged, and the feeding mechanism 3 is located in the loading device. 2 and the servo module 4; the feeding mechanism 3 includes a plurality of hobbing feeding mechanisms 5 arranged in a straight line; the material loading device 2 includes a plurality of feeding trays 6 corresponding to the hobbing feeding mechanism 5; The color material on the feeding tray 6 passes through the hobbing feeding mechanism 5 and the clamping block 7 in sequence;

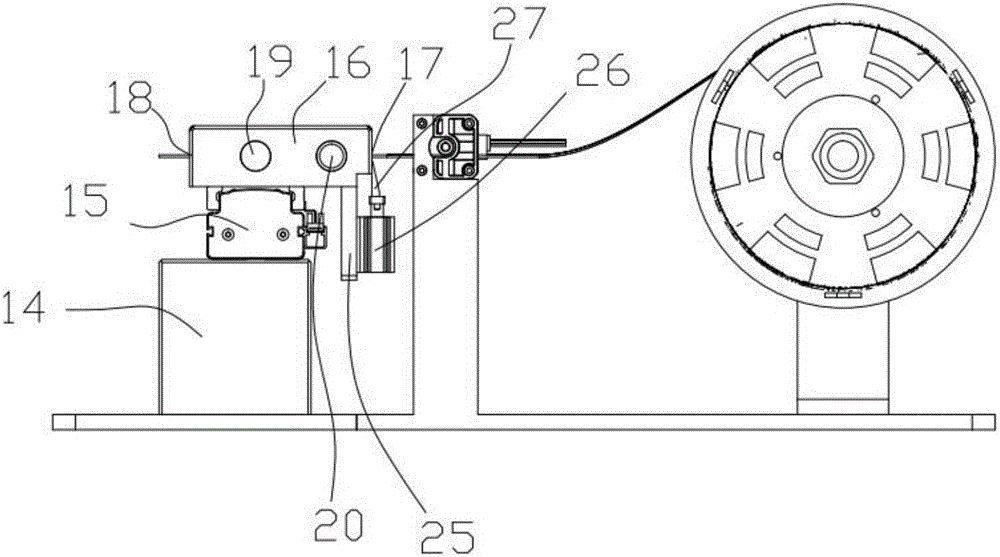

[0023] The servo module 4 is slidably connected with a clipping block 7 for transmitting and cutting the color material, wherein the servo module 4 includes a support seat 14, and the support seat 14 is provided with a slide rail 15, and the clip The material block 7 includes a hollow sliding block 16, the lower p...

Embodiment 2

[0028] The difference between this embodiment and Embodiment 1 is that the structure for softening the color material inside the hollow slider is a heating rod, and a clamping device is arranged parallel to the heating rod, and the clamping device is also inside the hollow slider. The feeding device 20 includes a clamping cylinder 21, the output end of the clamping cylinder 21 is provided with a clamping head 22, and the clamping head 22 is located on the straight line where the feeding port 17 and the feeding port are located. It includes two clips 23, a material chute 24 is arranged between the clips 23, the color material passes through the material chute 24, and the material chute 24 is provided with anti-skid lines. When the new color material is close to the original color material, the clamping head 22 starts to clamp for 3-5 seconds, and then automatically welds

[0029] The working mode of the present invention is:

[0030] 1. Carrier wire:

[0031] First select a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com