Omni wheel

A technology of omnidirectional wheels and hubs, applied in the field of omnidirectional wheels, can solve problems such as poor control accuracy, achieve the effects of improving transmission efficiency, good space utilization, and realizing high-precision control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several changes and modifications without departing from the concept of the present invention.

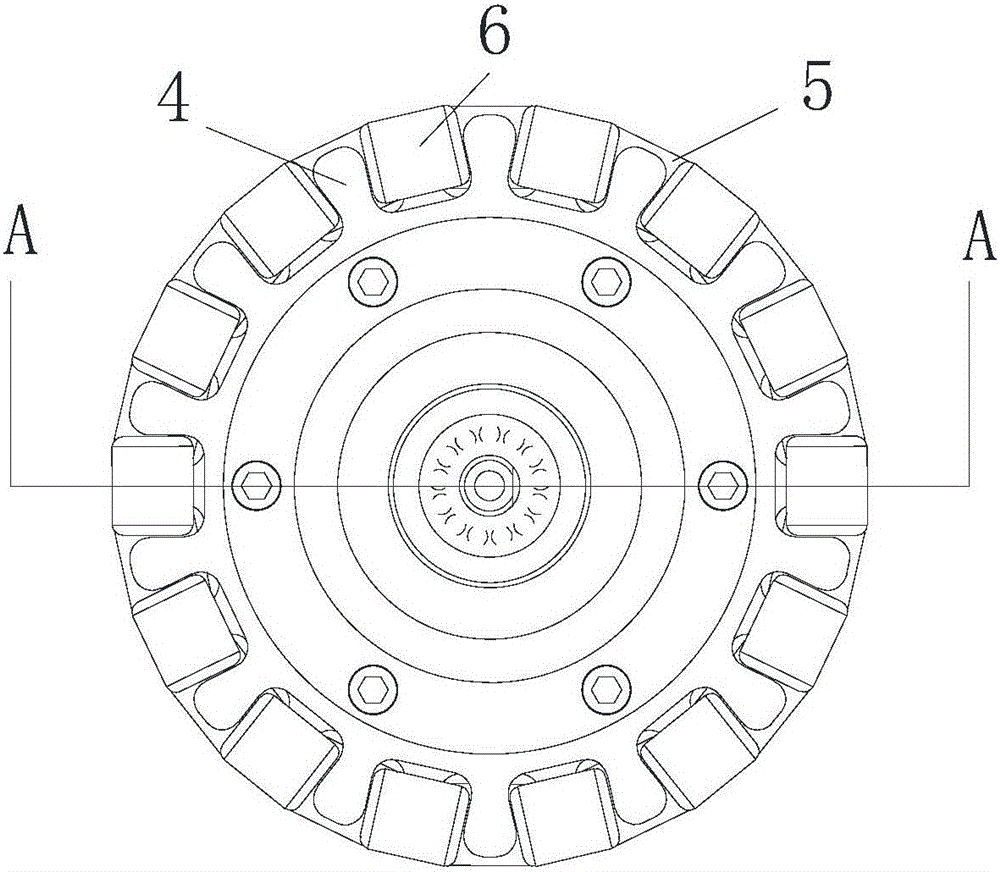

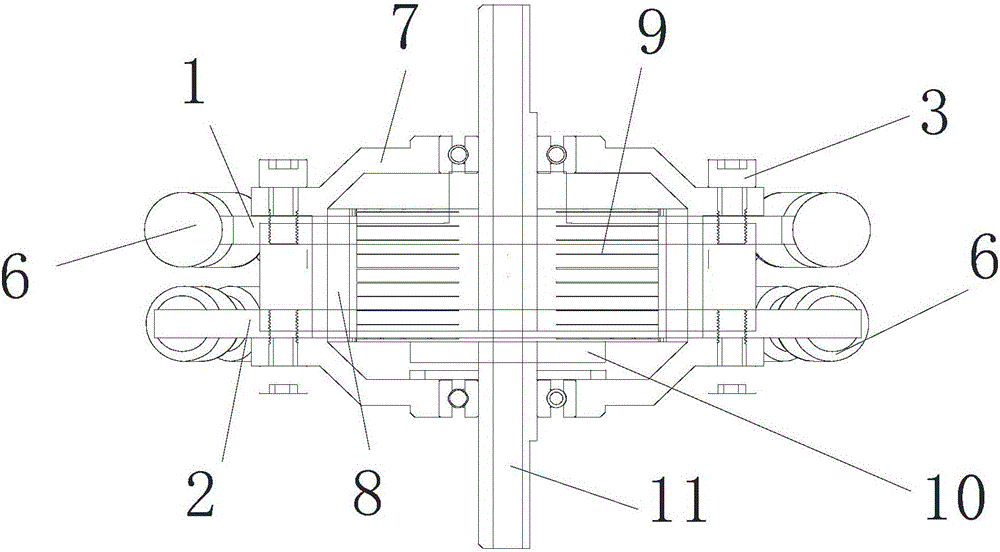

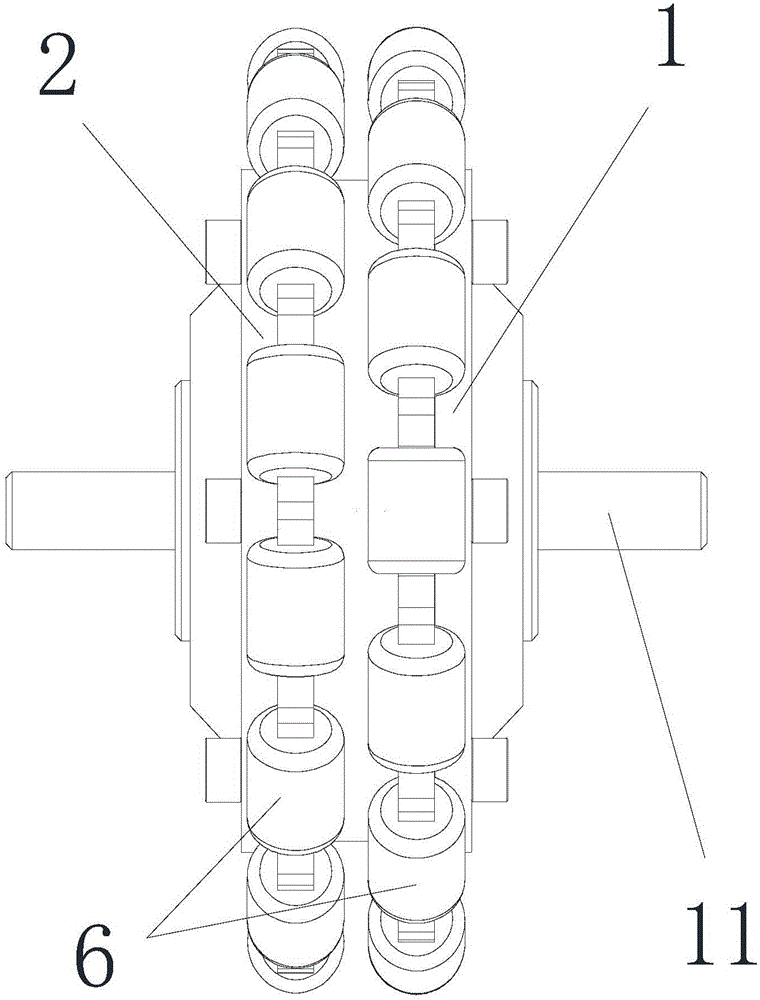

[0019] Such as Figure 1 ~ Figure 4 As shown, the present invention provides an omnidirectional wheel, comprising: a first hub 1 and a second hub 2 arranged in parallel and spaced apart. A plurality of installation teeth 4 are provided on the outer edges of the first hub 1 and the second hub 2 respectively, and installation grooves 5 are provided between adjacent installation teeth 4 and the first hub 1 and the second hub 2 are alternately arranged. The driven wheel 6 is arranged in the mounting groove 5 , and the normal of the cross section of the driven wheel 6 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com