Cable conduit cover plate carrying trolley

A technology of cable trench cover and handling trolley, which is applied to trolleys, motor vehicles, electrical components, etc., can solve the problems that affect the construction progress of cable laying, reduce the work efficiency of staff, and increase the work burden of construction personnel, so as to achieve safe and efficient charging , improve the aesthetics, increase the effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

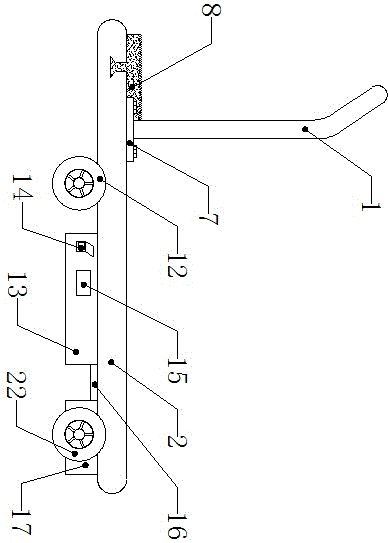

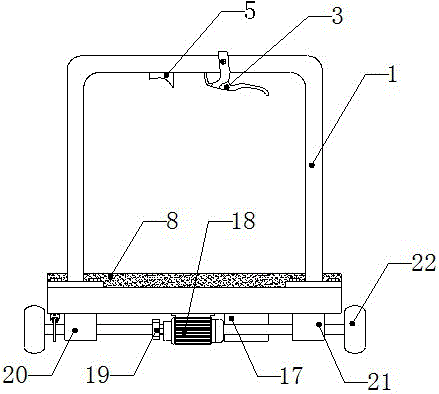

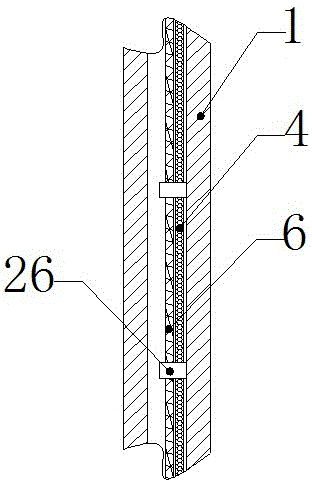

[0022] Such as Figure 1-6 As shown, a cable trench cover handling trolley, it includes a handrail 1 and a chassis 2, the handrail 1 is a door-shaped structure, the middle part of the upper end of the handrail 1 is fixed with a brake handle 3 by bolts, the brake handle 3 is connected with a brake line 4, the brake line 4 is threaded in the handrail 1, and the left side of the brake handle 3 is provided with a driving switch 5, and the driving switch 5 is connected with a control line 6, and the control line 6 It is installed inside the handrail 1; the lower end of the brake handle 3 is provided with a fixed plate 7, and the fixed plate 7 is fixed on the left end of the chassis 2 by bolts; the left side of the fixed plate 7 is laid with a rubber pad 8, and the rubber pad 8 The upper side of the pad 8 is provided with concave and convex lines 9, the lower end of the rubber pad 8 is provided with a T-shaped bump 10, and the left end of the upper surface of the chassis 2 is provid...

Embodiment 2

[0025] Such as Figure 1-6As shown, a cable trench cover handling trolley, it includes a handrail 1 and a chassis 2, the handrail 1 is a door-shaped structure, the middle part of the upper end of the handrail 1 is fixed with a brake handle 3 by bolts, the brake handle 3 is connected with a brake line 4, the brake line 4 is threaded in the handrail 1, and the left side of the brake handle 3 is provided with a driving switch 5, and the driving switch 5 is connected with a control line 6, and the control line 6 It is installed inside the handrail 1; the lower end of the brake handle 3 is provided with a fixed plate 7, and the fixed plate 7 is fixed on the left end of the chassis 2 by bolts; the left side of the fixed plate 7 is laid with a rubber pad 8, and the rubber pad 8 The upper side of the pad 8 is provided with concave and convex lines 9, the lower end of the rubber pad 8 is provided with a T-shaped bump 10, and the left end of the upper surface of the chassis 2 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com