Automobile body framework

A technology of automobile body and skeleton, applied in the direction of load-bearing body structure, vehicle parts, superstructure, etc., can solve the problems of cumbersome process, high cost input, difficult modification, etc., to achieve convenient battery maintenance, low production investment, easy design and production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

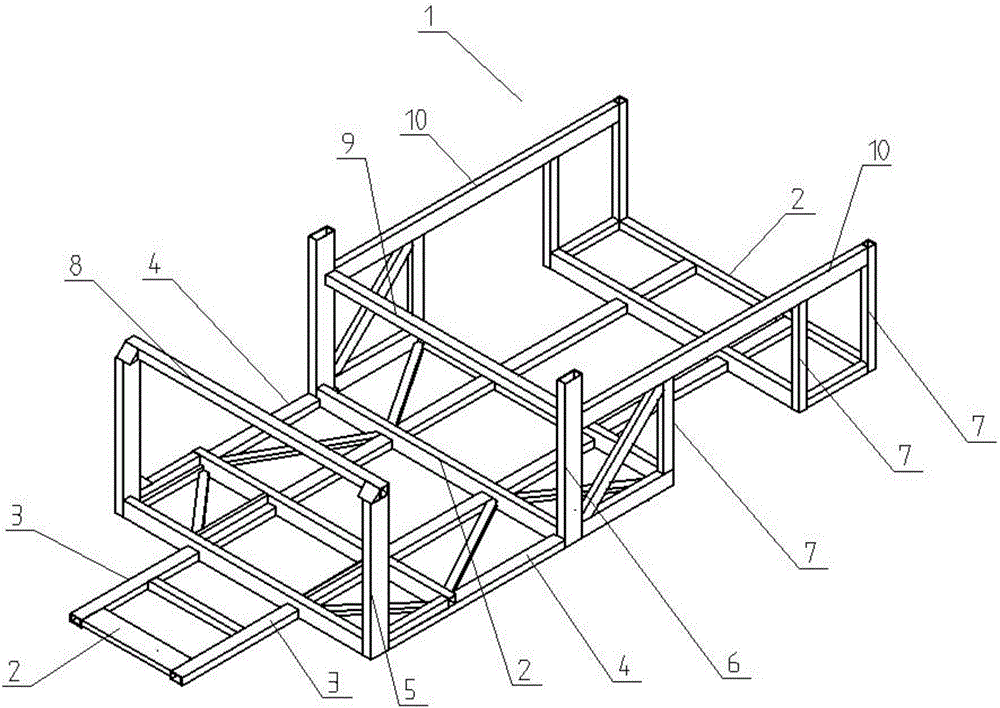

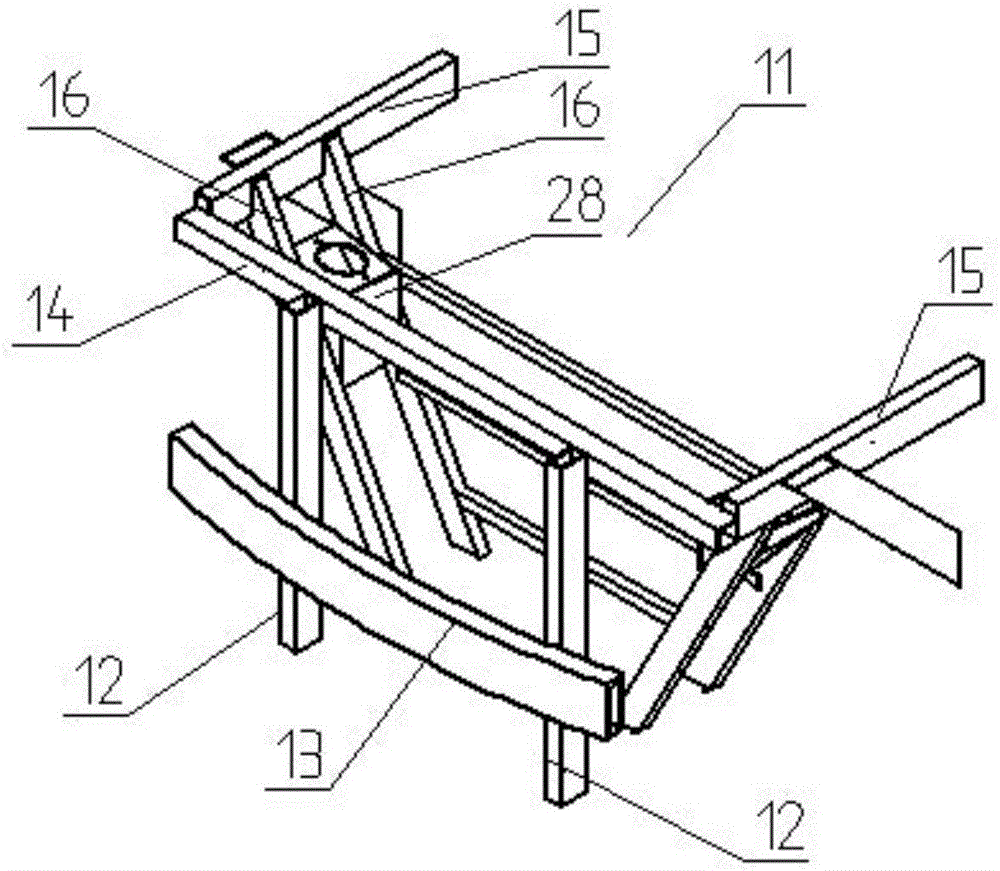

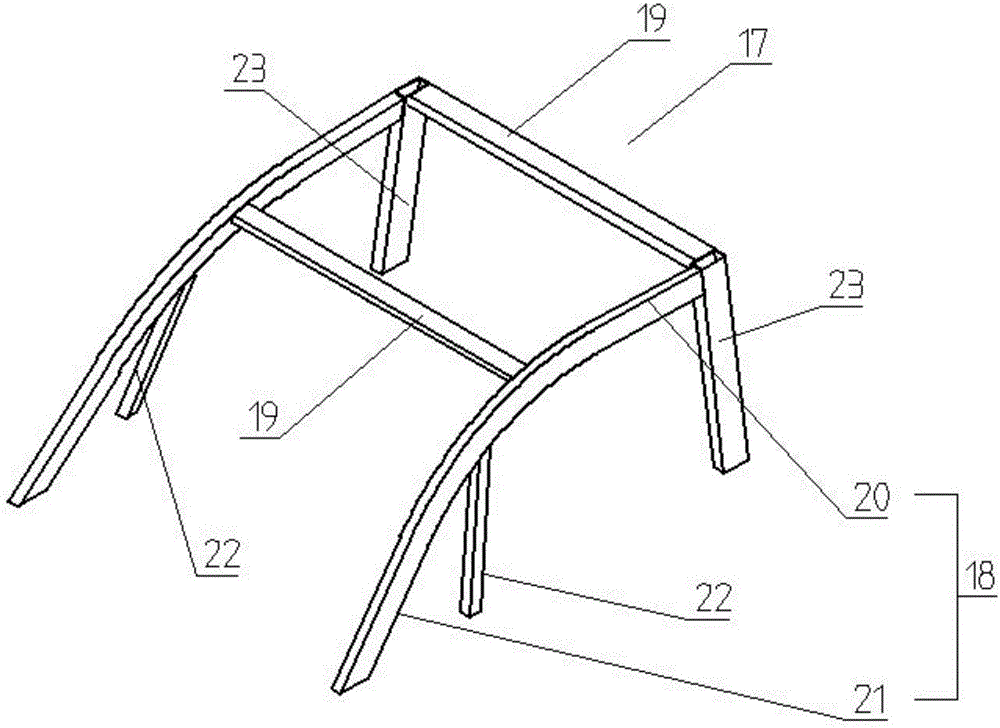

[0022] Car body frame, such as Figure 1 to Figure 7 As shown, it includes a bottom frame 1. The bottom frame 1 includes a bottom crossbeam 2 and a bottom crossbeam 3 perpendicular to the bottom crossbeam 2. The bottom crossbeam 3 penetrates the bottom crossbeam 2, and the bottom crossbeam 3 and the bottom crossbeam 2 stagger to form a square space , The bottom longitudinal beam 3 and the bottom cross beam 2 are provided with a first diagonal bracing reinforcement beam, the first diagonal bracing reinforcement beam is horizontally arranged on the bottom frame 1, and the strength of the bottom frame 1 is reinforced by the first diagonal bracing reinforcement beam. The two ends of a diagonal bracing reinforcement beam are connected to the diagonals of the square space. Both sides of the bottom cross beam 2 are provided with side longitudinal beams 4 connected with the bottom cross beam 2, and the side longitudinal beam 4 is provided with a first column 5 and arranged in the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com