Design method for wave rider and air inlet duct integrated configuration

A design method and the technology of the air inlet, which are applied to the combustion of the air inlet of the power unit, the air inlet of the turbine/propulsion device, transportation and packaging, etc., can solve the problem of destroying the original configuration of the waverider and the air inlet, It is difficult to achieve separate design, reduce the overall performance of the integrated system, etc., to achieve the effect of improving lift-to-drag ratio and flow capture characteristics, improving high lift-to-drag ratio and high flow capture characteristics, and strong engineering practicability

Inactive Publication Date: 2016-09-21

INHALE HYPERSONIC TECH RES CENT UNIT 63820 OF PLA

View PDF4 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

While artificial modification destroys the original configuration of the waverider and the inlet, it also brings unfavorable conditions such as non-uniform inflow of the inlet, which will reduce the overall performance of the integrated system, making it difficult to achieve the indicators designed separately

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0037] The content of the invention has made a clear and complete description of the technical solutions of the present invention, and will not repeat them again.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

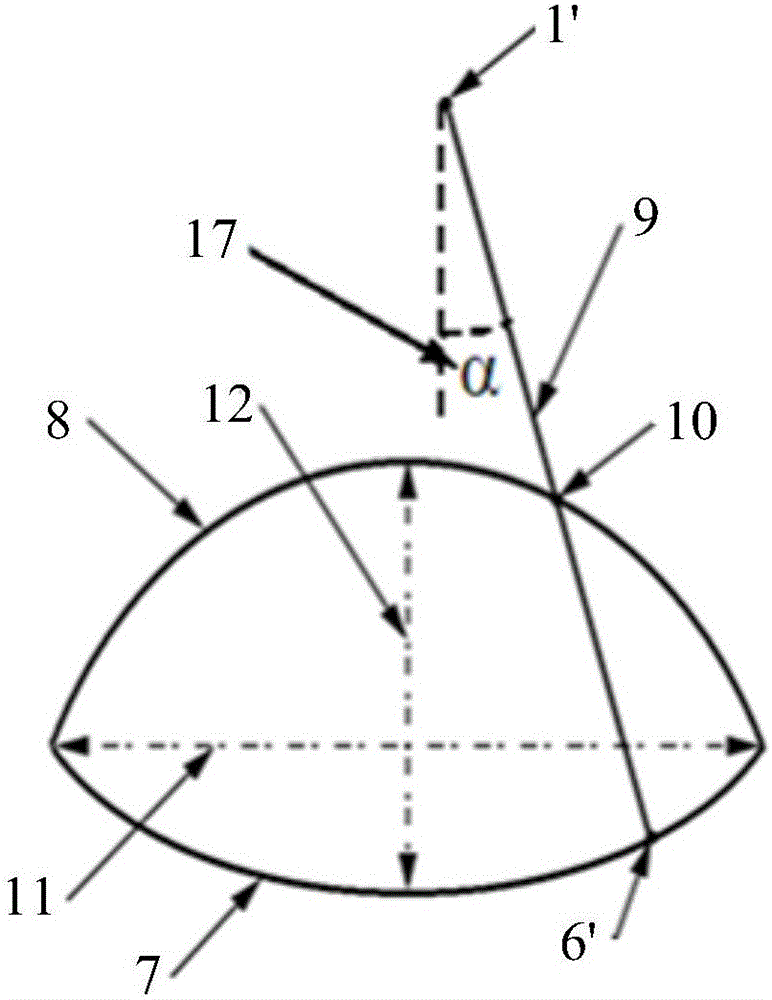

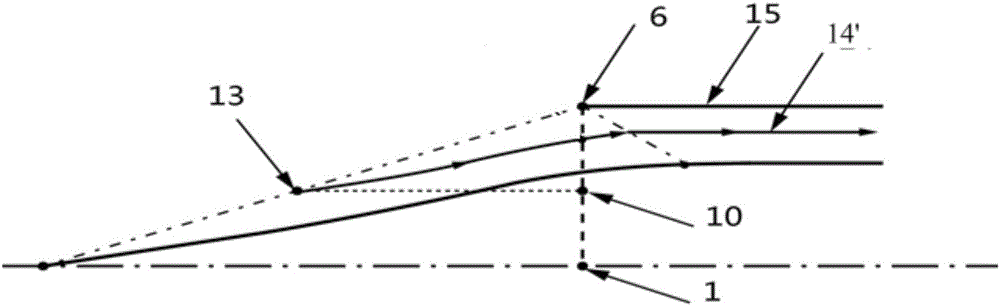

The invention discloses a design method for a wave rider and air inlet duct integrated configuration and belongs to the designing field of air-breathing hypersonic vehicle aerodynamics outlines and engine runners. The puzzled coupling design problem of a wave rider and an air inlet duct of a hypersonic vehicle for a long time is solved. The design method comprises the steps that 1, an axisymmetric benchmark flow field is determined; 2, a lip shock wave type line and a wave rider leading edge type line are defined; 3, an osculation plane is formed; 4, geometric matching is conducted; 5, a tracking flow line is determined; 6, a wave rider body compression type line is determined; 7, the steps from 3-6 are repeated, and the wave rider body compression surface is determined; and 8, other configuration bodies are determined. According to the design method for the wave rider and air inlet duct integrated configuration, the lift-drag ratio of the hypersonic vehicle can be remarkably increased, meanwhile, the good air inlet characteristic is maintained, and it is beneficial for the air-breathing hypersonic vehicle to overcome a resistance pushing barrier; and the wave rider compression surface of the obtained wave rider and air inlet duct integrated configuration is outwards convex, the overall wave rider body molded surface is fuller, the good volumetric characteristic is achieved, and the engineering realizability of the hypersonic vehicle is improved.

Description

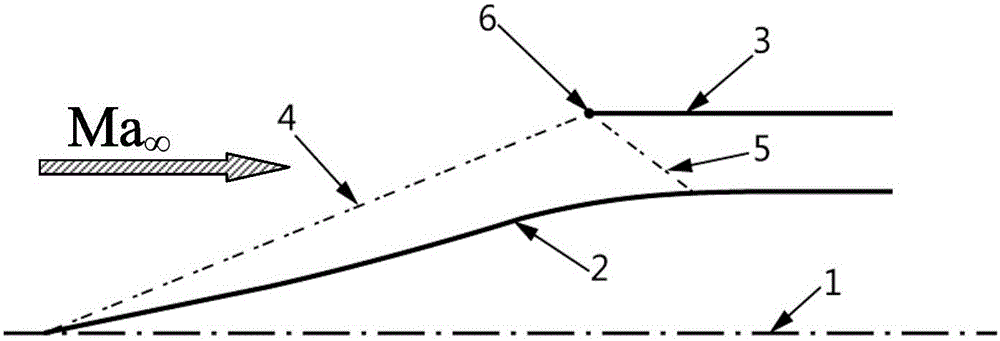

technical field [0001] The invention belongs to the field of air-breathing hypersonic vehicle aerodynamic shape and engine flow path design, and relates to the integrated configuration of a curved outer cone waverider and an air inlet and a design method thereof. Background technique [0002] Research on air-breathing hypersonic vehicles has been a research hotspot in the field of hypersonic flight for many years. However, with the increase of flight Mach number, the problem of thrust-drag matching is still one of the bottlenecks restricting the development of air-breathing hypersonic technology. [0003] The lift-to-drag ratio of an air-breathing hypersonic vehicle decreases with the increase of the flight Mach number. For an aircraft of a certain weight, its resistance will continue to increase with the increase of flight speed. At the same time, the specific impulse of the scramjet engine used Decreases as flight Mach number increases. In general, engine capture flow de...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B64F5/00F02C7/04B64D33/02

CPCB64D33/02B64D2033/026B64F5/00F02C7/04

Inventor 贺旭照乐嘉陵倪鸿礼刘伟雄贺元元吴颖川秦思周正

Owner INHALE HYPERSONIC TECH RES CENT UNIT 63820 OF PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com