Roll shaft curve conveyor

A technology of conveyors and curves, which is applied in the field of roller curve conveyors, and can solve problems such as affecting normal conveying and blockage at turns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

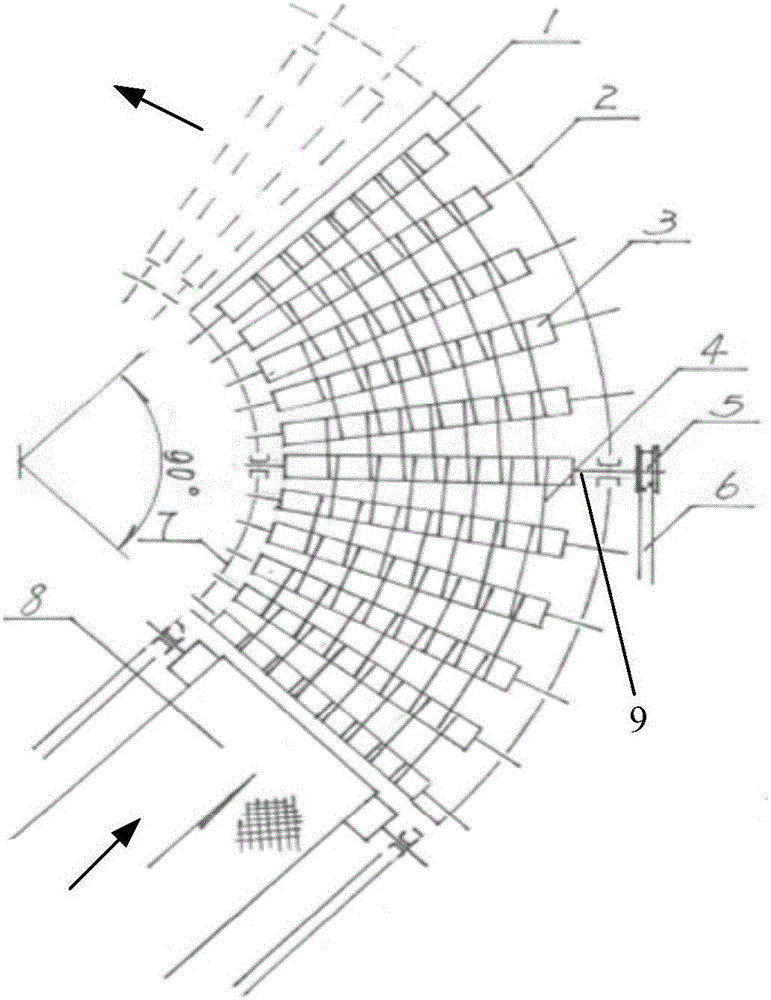

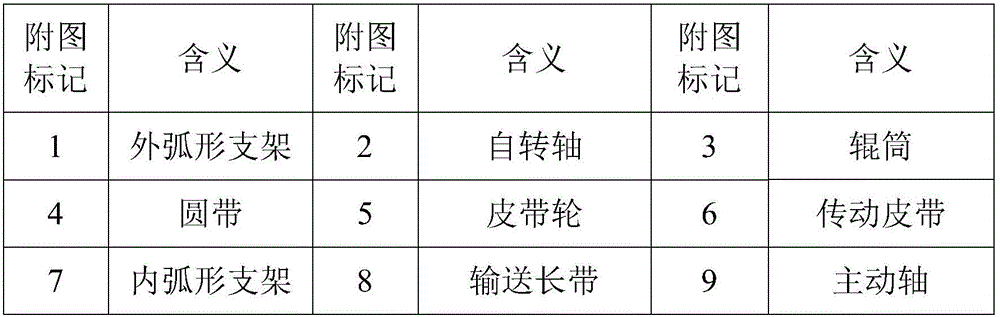

[0023] Such as figure 1 As shown, the roller curve conveyor includes an outer arc support 1 and an inner arc support 7, and there are several rotation shafts 2 and at least one active support between the outer arc support 1 and the inner arc support 7. The shaft 9, the rotation shaft 2 and the driving shaft 9 are distributed at intervals along the running direction, the driving shaft 9 and the rotation shaft 2 are provided with rollers 3, and the outer circular surfaces of the driving shaft roller and the rotation shaft roller are provided with multiple paths. The grooves set on the driving shaft roller are evenly spaced and parallel to each other, the grooves set on the self-rotating shaft roller are evenly spaced and parallel to each other, and the two adjacent rollers are stretched in the opposite radial annular grooves. There is a round belt 4 tightly, and the round belt installed in the radial annular groove protrudes from the roller surface of the roller.

[0024] Where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com