Single-drive two-way type AGV trolley for non-flat ground

A two-way, non-flat technology, applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of poor ability to withstand gravity, limited scope of application, influence on navigation, etc., to achieve improved shock resistance and compact structure , good flexibility and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

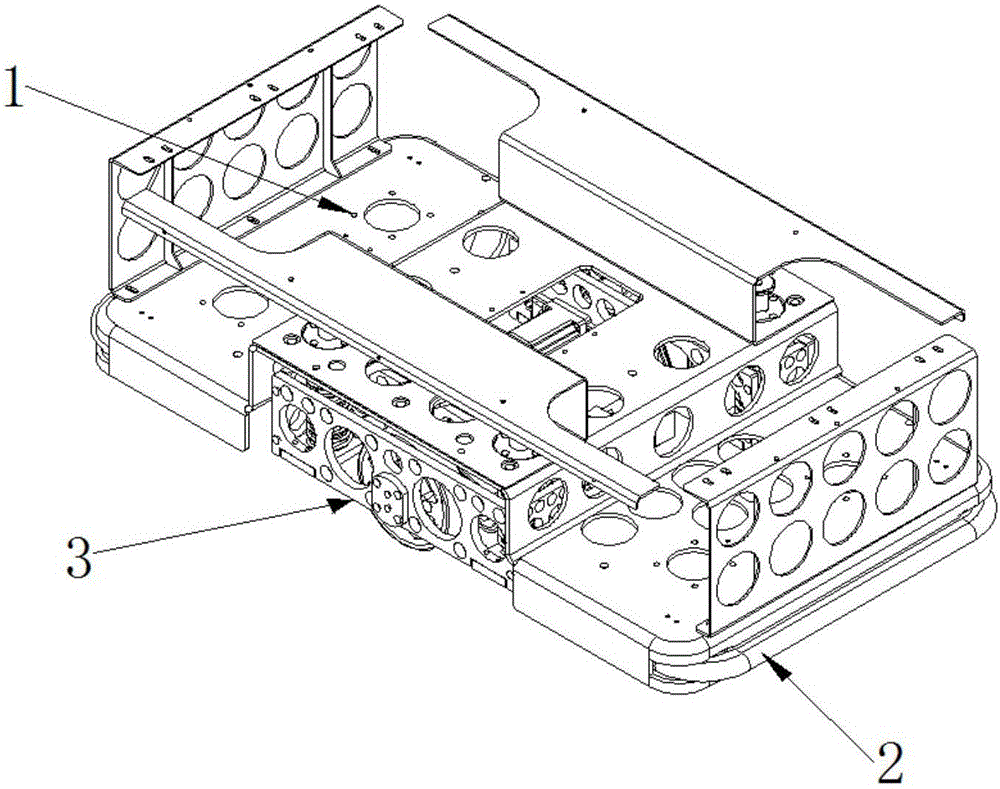

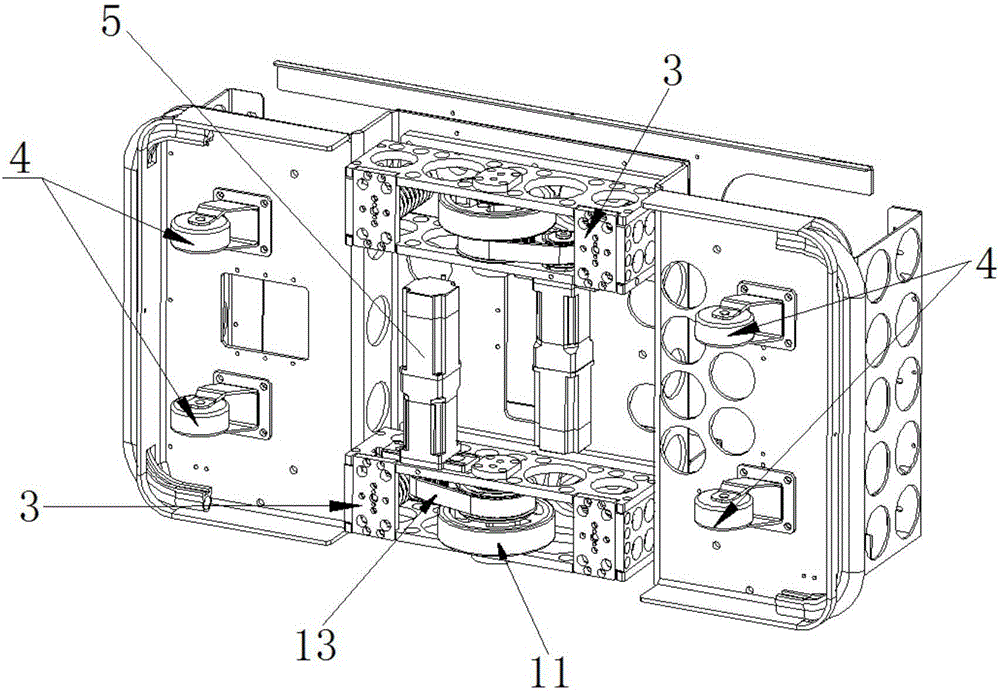

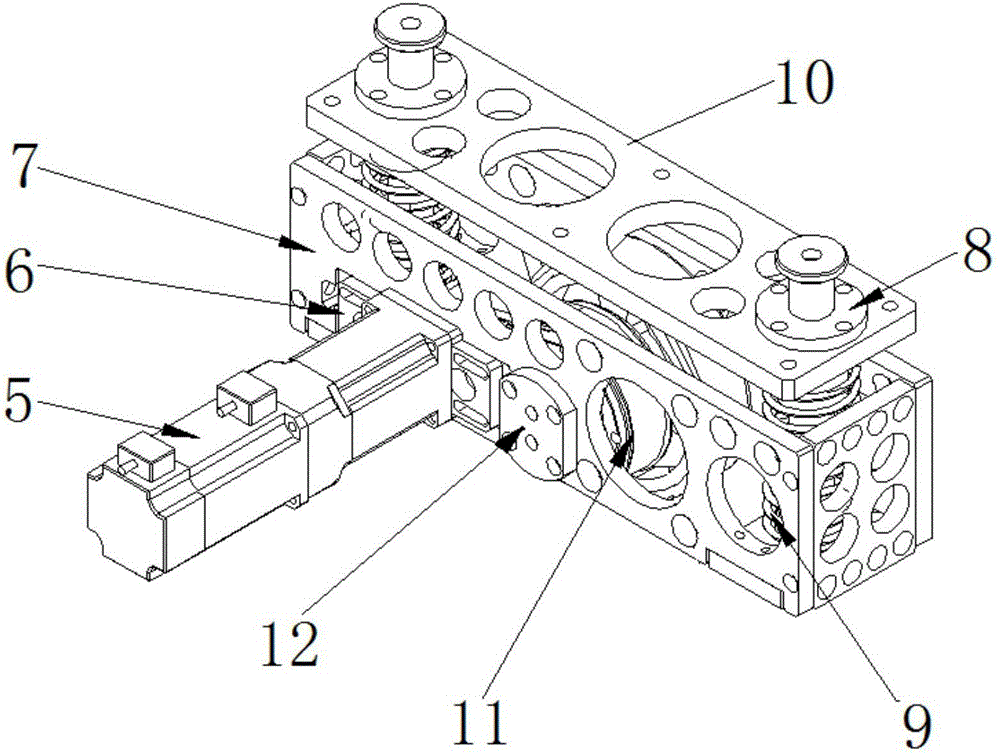

[0032] Such as Figure 1-4 Shown is a single-drive two-way AGV trolley for use on uneven ground. The trolley includes a car body frame 1 and a pair of suspension drive systems 3 symmetrically arranged on both sides of the bottom of the car body frame 1 . The bottom of the vehicle body frame 1 is provided with driven casters 4, and the front end and rear end of the vehicle body frame 1 are respectively provided with anti-collision bumpers 2. The suspension drive system 3 includes a suspension mechanism and a drive mechanism. The suspension mechanism includes a suspension frame body 7 arranged at the bottom of the vehicle body frame 1, a suspension frame body cover plate 10 adapted to the suspension frame body 7, and two evenly arranged on the suspension frame body. Between the body 7 and the suspension frame body cover plate 10 and the spring shock absorber unit that the suspension frame body 7 is elastically connected with the suspension frame body cover plate 10, the suspensi...

Embodiment 2

[0036] In this embodiment, the suspension mechanism includes 4 spring shock-absorbing units, and the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com