Vacuum adsorption lifting appliance and use method thereof

A technology of vacuum adsorption and vacuum suction cups, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as damaged connections of cables and cable connectors, unstable adsorption of vacuum devices, and bruising of thin aluminum plates, etc., so as to reduce maintenance costs, Convenient and fast maintenance, reliable adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

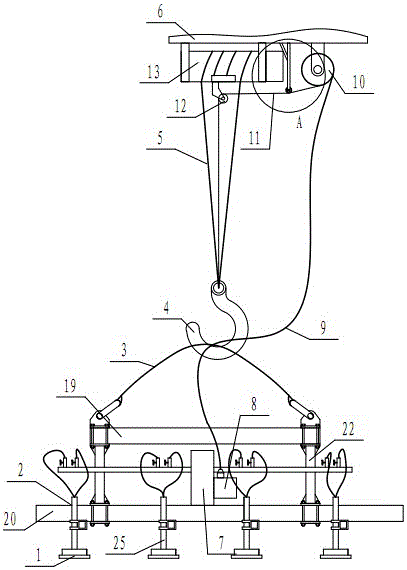

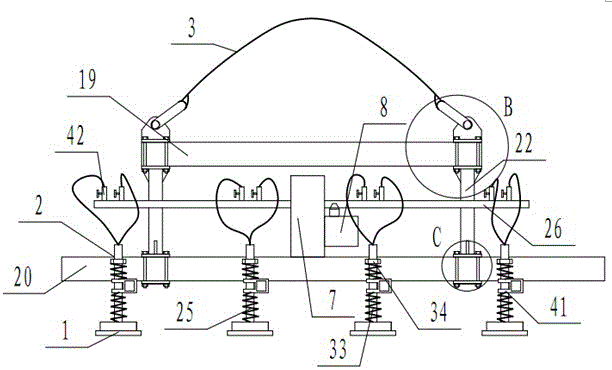

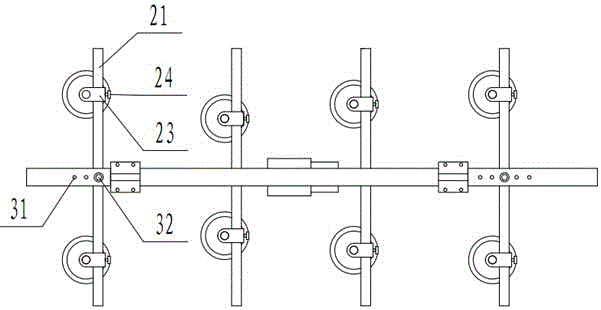

[0032] Embodiment 1: as Figure 1-Figure 7 As shown, a vacuum suction hanger includes a plurality of vacuum suction cups 1, and the plurality of vacuum suction cups 1 are symmetrically installed on a support frame 2 at intervals. 5 is connected on the walking box 6.

[0033] Preferably, each of the above-mentioned vacuum chucks 1 is connected to the vacuum device 7 through a pipeline, the vacuum device 7 is installed on the support frame 2, and the connected pipeline is a hose, which is connected in parallel to the output pipeline 26 of the vacuum device 7, and the output The pipeline 26 is fixedly connected to the middle part of the vertical connecting beam 22, and a valve 42 is installed on the pipeline connecting the output pipeline 26 to each section of the vacuum chuck 1.

[0034] Preferably, the above-mentioned vacuum device 7 includes a vacuum pump 8, the vacuum pump 8 is connected with the free end of the cable 9 for power supply or control, and the other end of the c...

Embodiment 2

[0043] Embodiment 2: a kind of use method of vacuum adsorption sling, the method comprises the following steps:

[0044] (1) The diameter of the vacuum suction cup is 280-330mm, and eight vacuum suction cups are set on the suction cup beam, with the attached beam as the center line, and four pairs of vacuum suction cups are arranged on both sides with symmetrical intervals;

[0045] (2) Adjust the bottom surfaces of the eight vacuum suction cups to keep the same surface, and the error of the same surface is 0.3-0.8mm;

[0046] (3) Adjust the vertical and horizontal distances of the eight vacuum suction cups, the distance between every two pairs of vacuum suction cups is equal, the distance is 480-520mm, the distance between each pair of vacuum suction cups is not equal, and the distance between each pair of vacuum suction cups from left to right is the width of the thin aluminum plate 0.8 times, 0.5 times, 0.65 times and 0.8 times;

[0047] (4) Connect eight vacuum suction cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com