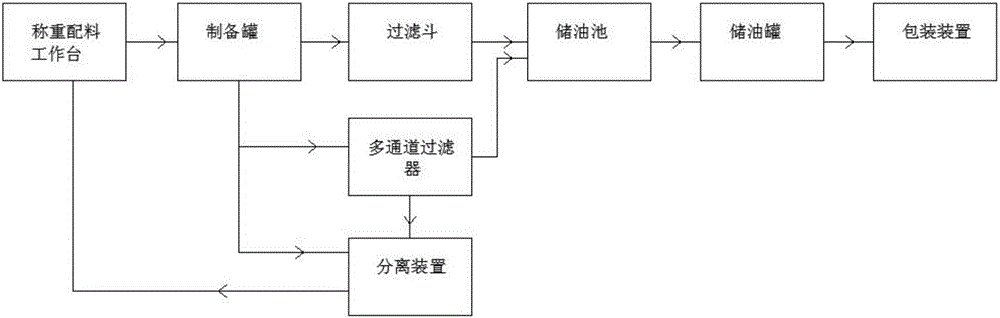

Installation structure of three-dimensional lubricating oil blending system

A system installation, lubricating oil technology, applied in the direction of lubricating compositions, etc., can solve the problems of high labor intensity, worker experience, technical requirements and quality cannot be guaranteed to be completely consistent, low production efficiency, etc., to reduce labor intensity and labor quantity. , The effect of simple structure and reasonable space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

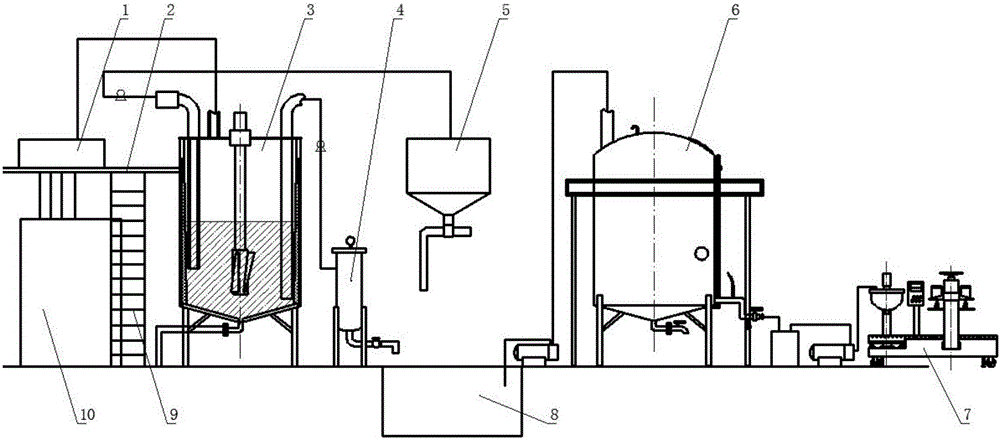

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0013] An installation structure of a three-dimensional lubricating oil blending system, including a weighing and batching device 1, a preparation tank 3, a filter hopper 5, a multi-channel filter 4, an oil storage tank 8, an oil storage tank 6, and a packaging device 7, and the weighing and batching device The input end of the weighing batching device is connected to the raw material warehouse 10, and the output end of the weighing batching device is connected to the input end of the preparation tank. There are multiple preparation tanks in this embodiment, and the pulse type preparation tank or the stirring type preparation tank is selected according to the lubricating oil type; There are two output...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com