Aluminum base alloy soluble in water and aqueous medium environments and preparation method thereof

An aluminum-based alloy, water medium technology, applied in the field of aluminum alloy materials, can solve the problem that tools such as soluble bridge plugs and ball seats have not yet been developed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

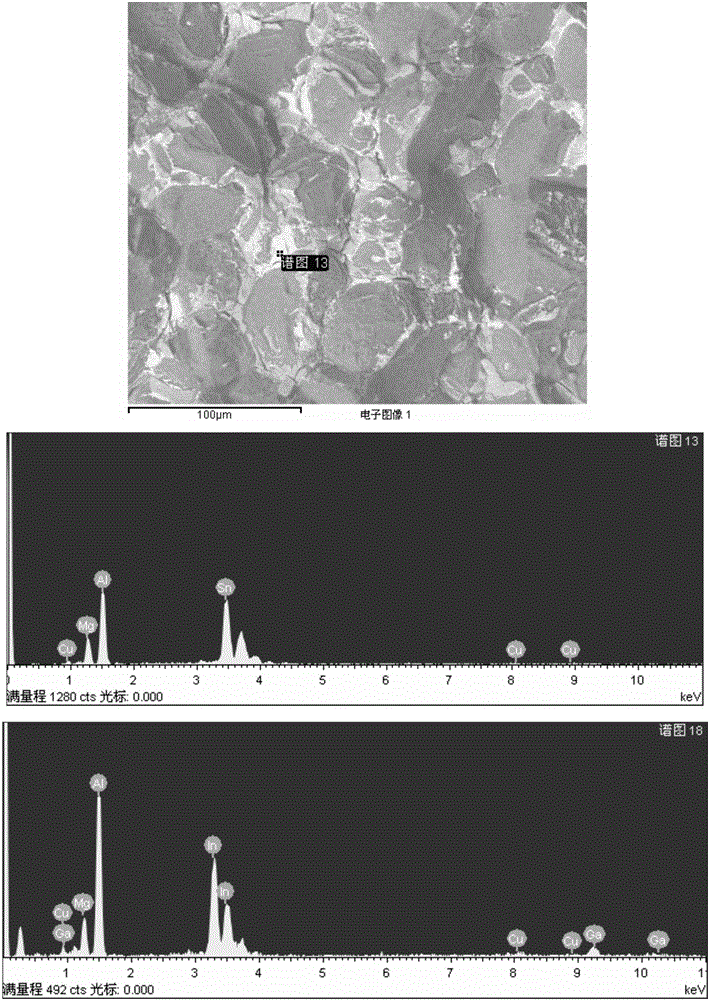

[0025] By alloy Al 91 Mg 3 Cu 1 Si 0.2 Ti 0.1 Ga 3.2 In 1 sn 0.5 The mass ratio of each metal is accurately weighed, and the aluminum is first melted in a crucible melting furnace, and the melting temperature of the alloy is 730°C. The other metals to be added are melted, and a layer of slag-removing covering agent (a mixture of KCl and MgCl) is sprinkled on the surface of the molten aluminum. Add aluminum titanium boron (Al 94 Ti 5 B) After the grain refiner, the molten aluminum is refined for 15 minutes. After the molten aluminum is left to stand for a period of time, the oxidized slag on the surface of the molten aluminum is removed. The molten aluminum is cast in the mold, and after the molten aluminum is completely solidified, the cast alloy is put into a quenching furnace and heated to 490°C for 1.5 hours. The alloy is taken out and quenched in oil, and after quenching, the casting is kept in an aging furnace at 180°C for 16 hours.

[0026] The average grain ...

Embodiment 2

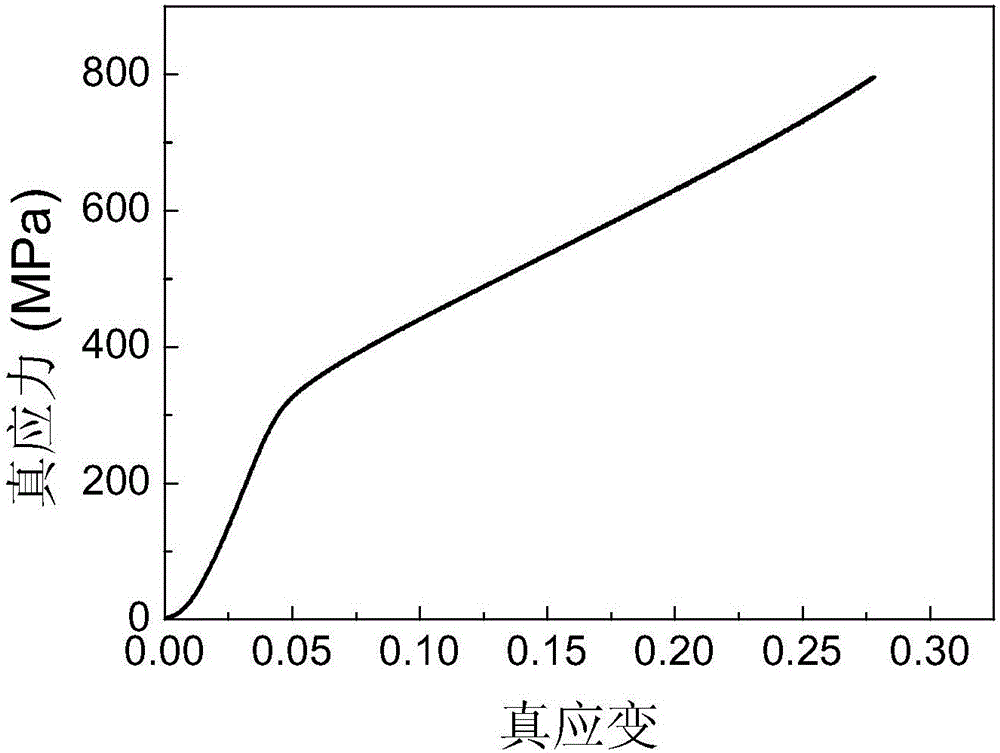

[0028] Repeat the process of Example 1 to prepare Al 90 Mg 4 Cu 2 Si 0.2 Ti 0.1 Ga 2.5 In 0.8 sn 0.4 alloy. The quenching temperature is 470°C, and the temperature is kept for 1.2 hours. The alloy is quenched in oil, and the aging temperature of the casting after quenching is 160°C for 18 hours. The yield strength of the alloy is 332MPa, and the alloy is not broken when the deformation exceeds 25%. The alloy has a hardness value of 158 under a 200g load.

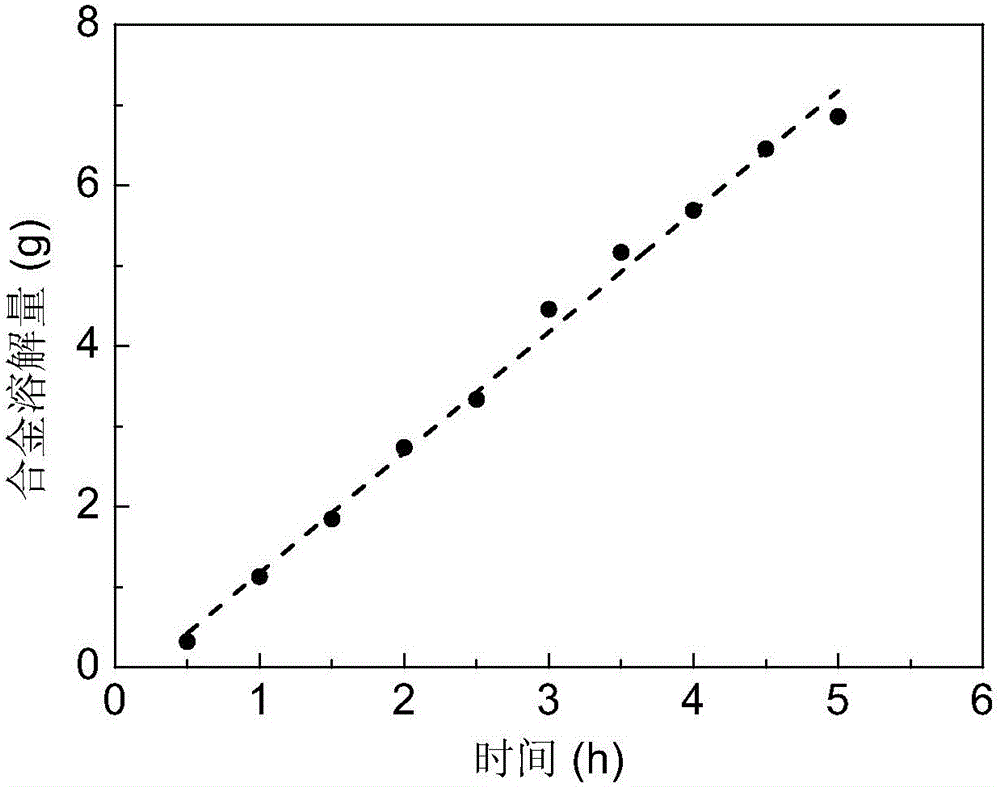

[0029] The alloy starts to react with water at 58°C, and the average dissolution rate of a cube alloy with a size of 2cm at a water temperature of 90°C is 2.4g / h (Table 1). Compared with the alloy in Example 1, the alloy has lower strength, lower initial reaction temperature, and lower dissolution rate.

Embodiment 3

[0031] Repeat the process of Example 1 to prepare Al 91Mg 3.5 Cu 1 Ga 3 In 1 sn 0.5 alloy. The quenching temperature of the alloy is 470°C, and the temperature is kept for 1.8 hours. The aging temperature is 190°C, and the temperature is kept for 18 hours. The yield strength of the alloy during compression is 305MPa, and the alloy is not broken when the deformation exceeds 25%. The alloy has a hardness value of 130 under a 200g load.

[0032] The alloy starts to react with water at 50°C, and the average dissolution rate of a cube alloy with a size of 2cm at a water temperature of 90°C is 6.6g / h (Table 1). Compared with the alloy in Example 1, the yield strength and hardness of the alloy are greatly reduced, the initial reaction temperature is lowered, and the dissolution rate is increased.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com