Construction method of corbel reinforcement for gate pier

A construction method and gate pier technology, applied in water conservancy projects, sea area engineering, infrastructure engineering, etc., can solve the problems of small construction space of high-altitude piers, large amount of high-altitude operations, and cross-interference of processes, so as to avoid construction interference, Improve work efficiency, easy and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

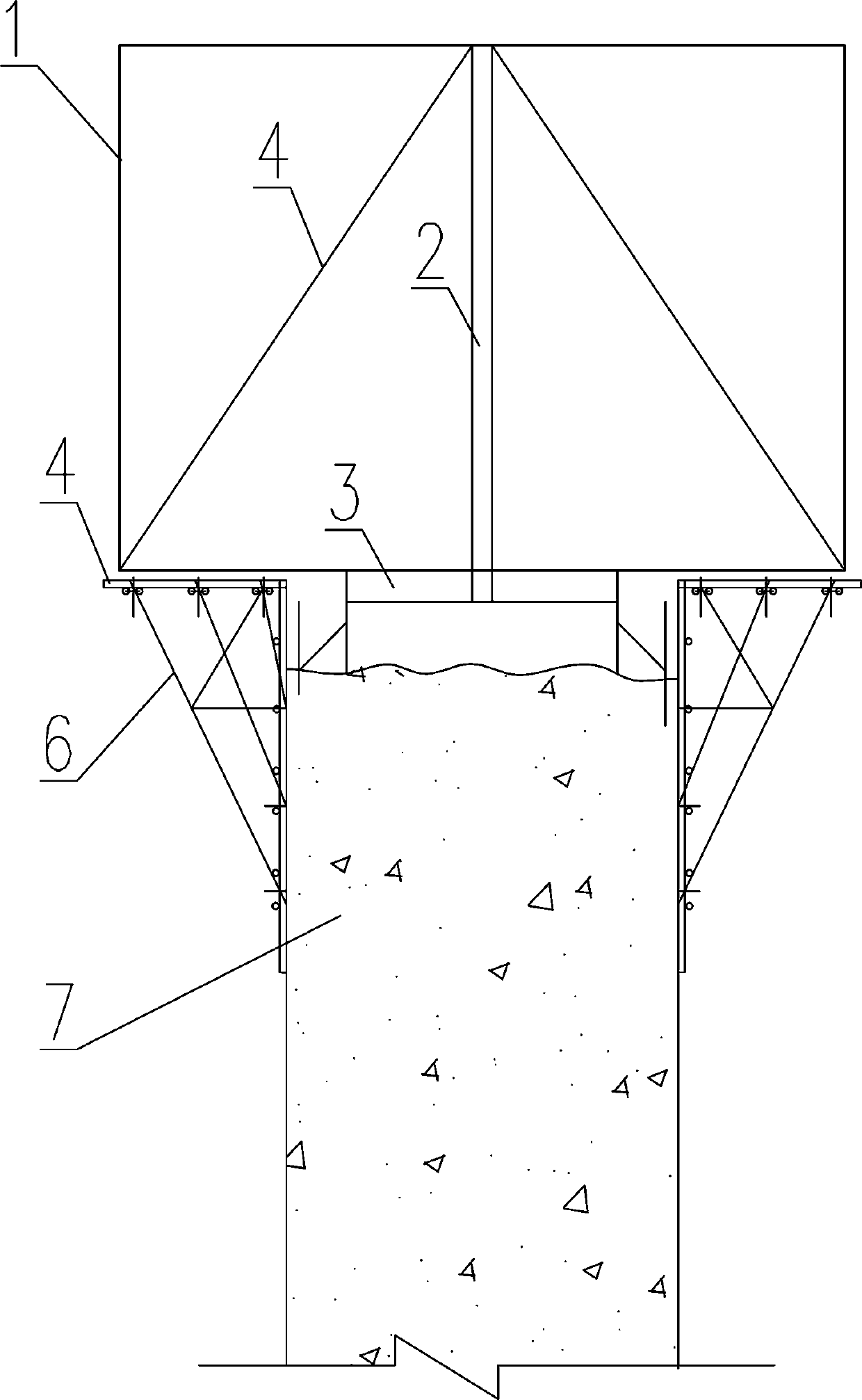

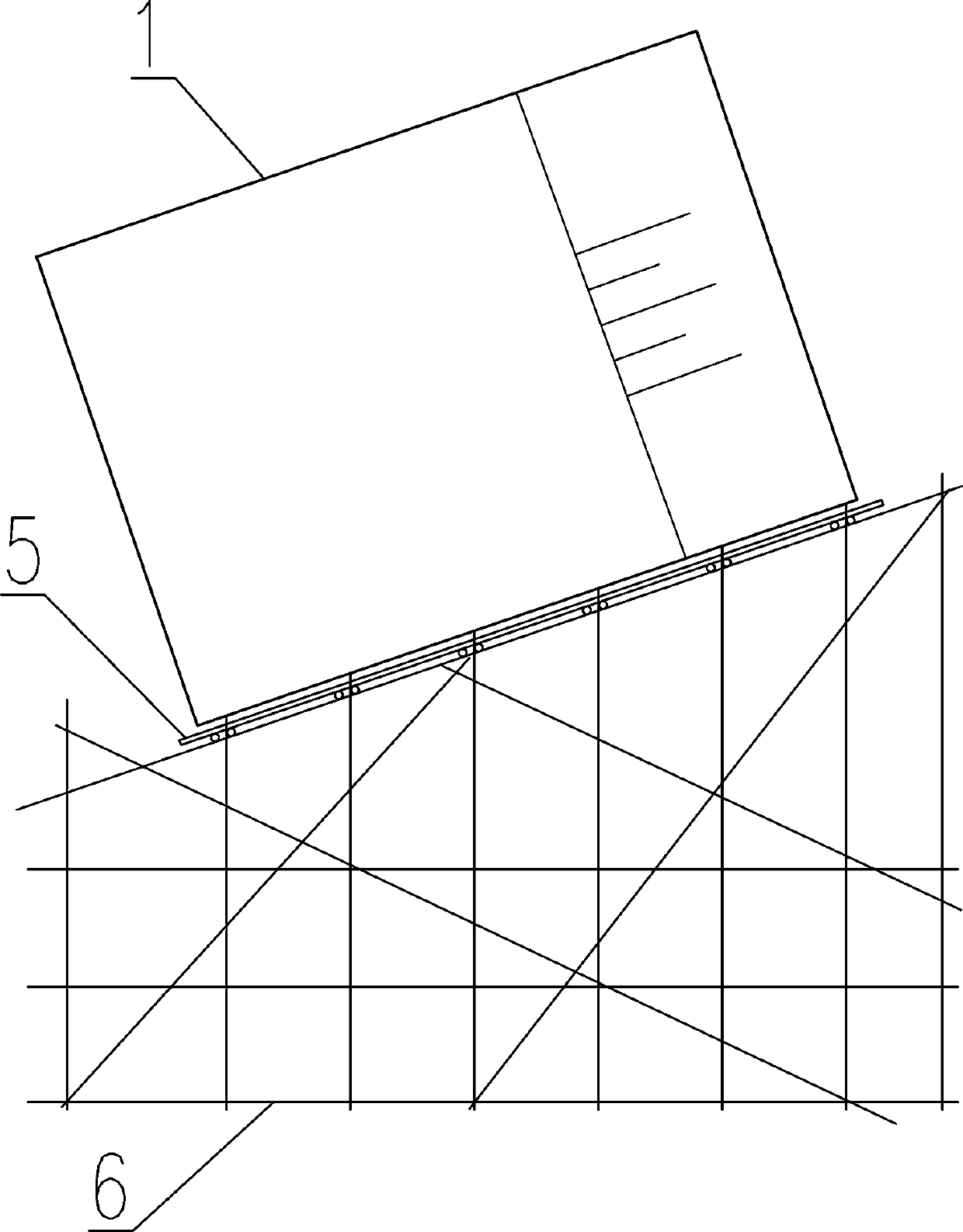

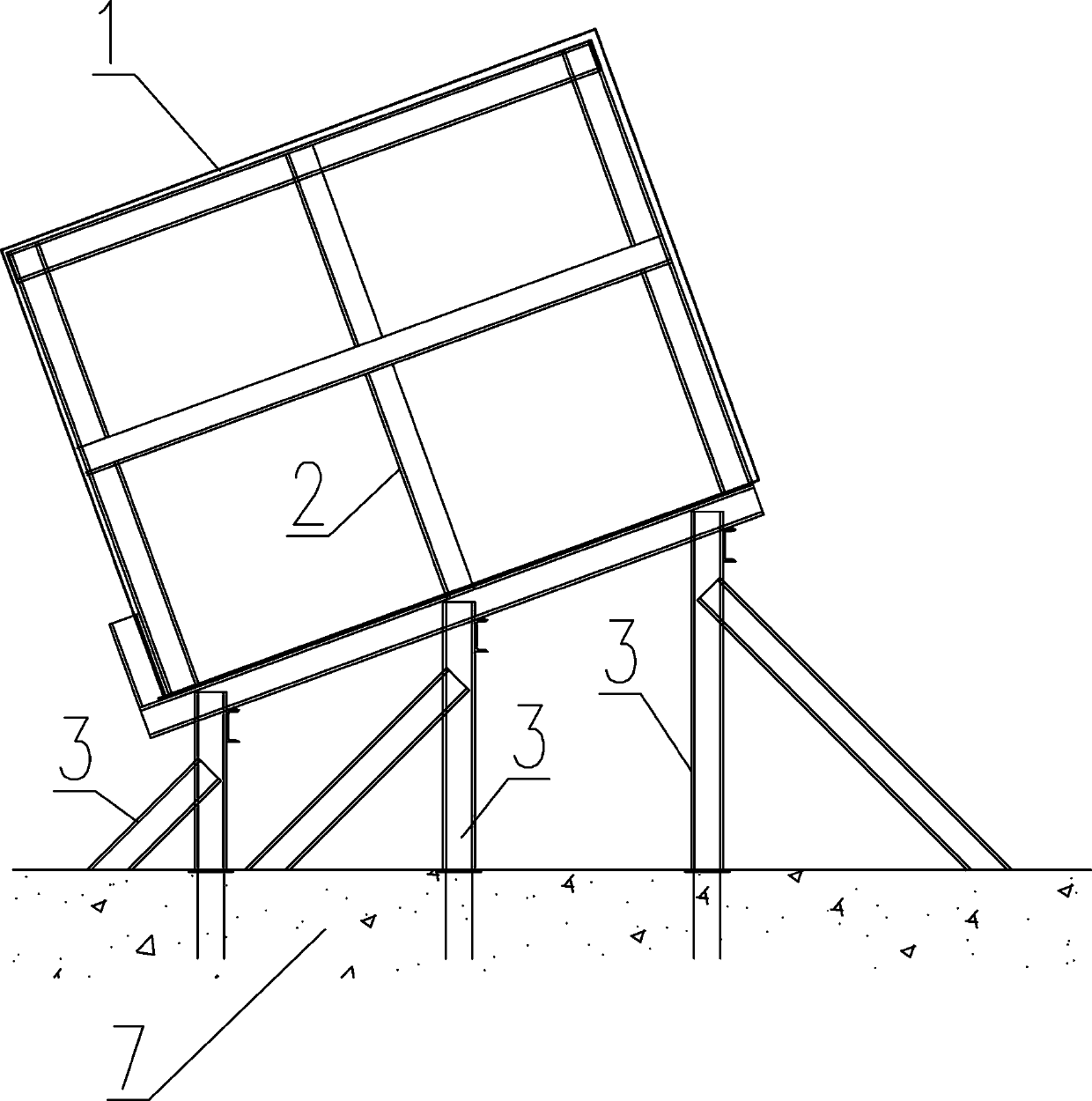

[0032] Such as Figure 1~5 Among them, a construction method for gate pier corbels, comprising the following steps:

[0033] 1. Make a reinforcement cage body 1 on a site other than the gate pier, and weld an inner bracket 2 inside the reinforcement cage body 1; preferably, the channel steel inner bracket 2 is arranged in the middle of the reinforcement cage body 1.

[0034] Place sleeper slots on a flat site near the steel bar processing area. The slots are used to accurately locate and design the distance between the main bars at the bottom of the corbel. Lay out the reinforcement cage body 1 bottom steel mesh according to the design drawing, and process the inner brackets 2 of corresponding specifications and sizes at the same time. The inner bracket 2 is processed by channel steel. In this example, 18# channel steel is preferably used, and the inner support 2 forms a frame structure, such as figure 1 , 3 , as shown in 4. The inner bracket 2 is welded with the bottom s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com