Improved Tetrahedral Throwing Material Used in Interception Engineering

A tetrahedral, improved technology, applied in infrastructure engineering, construction, etc., can solve the problems of poor material stability, long-lasting hydrodynamic action, and unsatisfactory action, and achieve increased water permeability, reduced flow and upstream and downstream problems. Water level drop, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

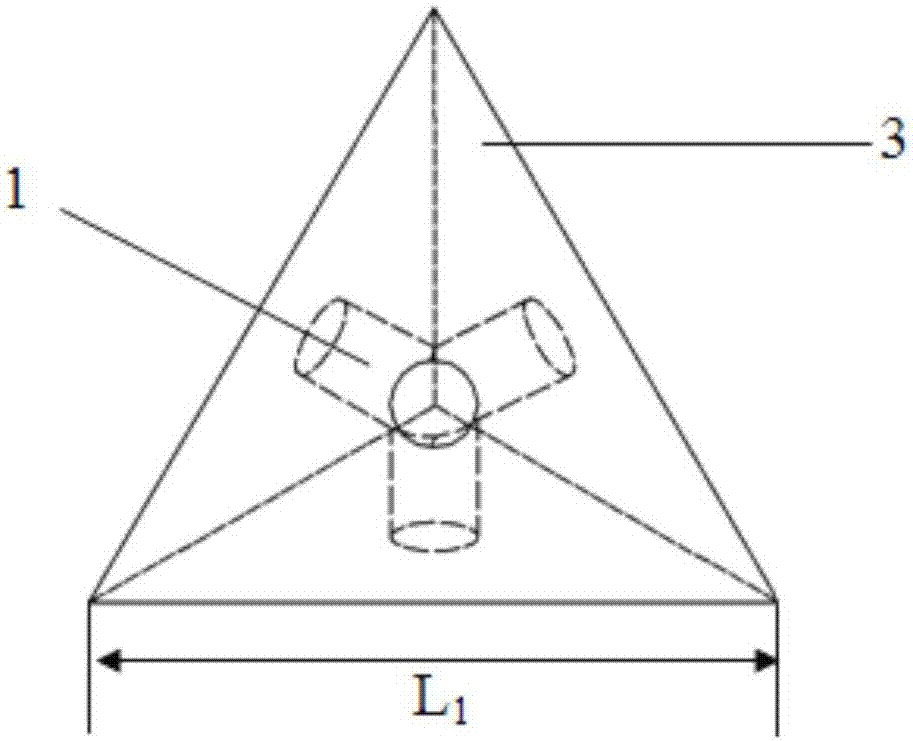

[0027] In this embodiment, the schematic diagram of the structure of the improved tetrahedron throwing material used in the interception project is shown in figure 2 , including a tetrahedron body 3, the tetrahedron body 3 is a regular tetrahedron, the tetrahedron body is provided with a through hole 1 that communicates with each other and runs through each face of the tetrahedron body, and the edge length L of the regular tetrahedron 1 =2.0m, through hole 1 is made up of four cylindrical holes with the same shape, one end aperture of each cylindrical hole is located at the center of each face of the tetrahedron body, and the other end aperture is located at the center of the tetrahedron body, And at the center of the tetrahedron body, the total volume of the through hole 1 accounts for 35% of the total volume of the tetrahedron body. The throwing material is made of concrete, and the density of the tetrahedron body is 2400kg / m 3 .

Embodiment 2

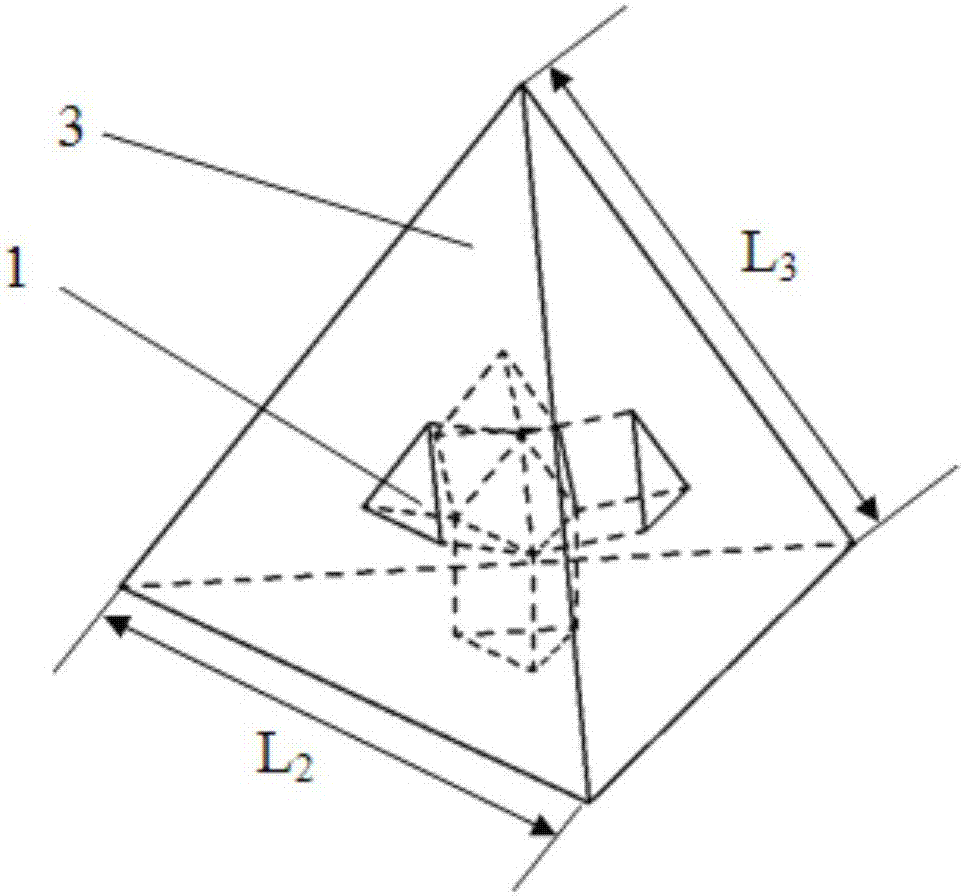

[0029] In this embodiment, the schematic diagram of the structure of the improved tetrahedron throwing material used in the interception project is shown in image 3 , comprising a tetrahedral body 3, the tetrahedral body 3 is a regular triangular pyramid, the tetrahedral body is provided with a through hole 1 that communicates with each other and runs through each face of the tetrahedral body, the side length L of the equilateral triangular base of the regular triangular pyramid 2 =3.2m, the waist length L of the three isosceles triangle sides of the regular triangular prism 3 =2.8m, the through hole 1 is made up of four same-shaped cross-sections that are triangular holes, each of which has a triangular cross-section. One end of the hole is located at the center of each face of the tetrahedral body, and the other end of the hole is located at the center of the tetrahedral body. and at the center of the tetrahedron body, the total volume of the through hole 1 accounts for 5% ...

Embodiment 3

[0031] In this embodiment, the schematic diagram of the structure of the improved tetrahedron throwing material used in the interception project is shown in Figure 4 , including a tetrahedron body 3, the tetrahedron body 3 is a regular tetrahedron, the tetrahedron body is provided with a through hole 1 that communicates with each other and runs through each face of the tetrahedron body, and the edge length L of the regular tetrahedron 1 =4.5m, through hole 1 is made up of four cylindrical holes with the same shape, one end aperture of each cylindrical hole is positioned at the center of each face of the tetrahedron body, and the other end aperture is positioned at the center of the tetrahedron body, And at the center of the tetrahedron body, the bottom surface of the tetrahedron body is provided with a through-bottom groove 2, and the groove 2 communicates with the opening of the through hole on the bottom surface of the tetrahedron body, and the through hole 1 and The total ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com