Deep sea drilling remote wireless control well cementation special equipment

A deep-water drilling, remote wireless technology, applied in wellbore/well components, earthwork drilling, sealing/packing, etc., can solve the problems of not fully meeting the needs of cementing, large turning space, inconvenient operation, etc., to achieve convenient matching , rapid action, and the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

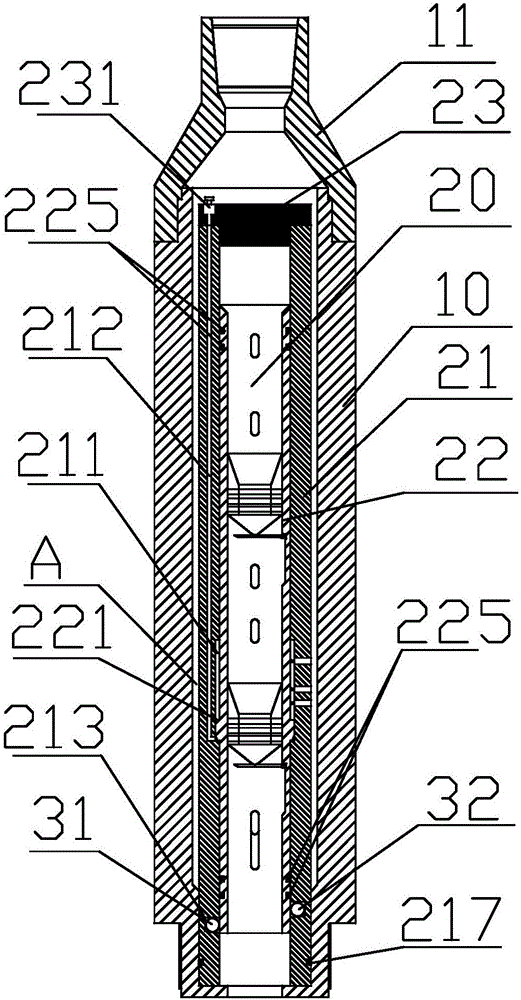

[0033] Below in conjunction with accompanying drawing, technical solution of the present invention is described:

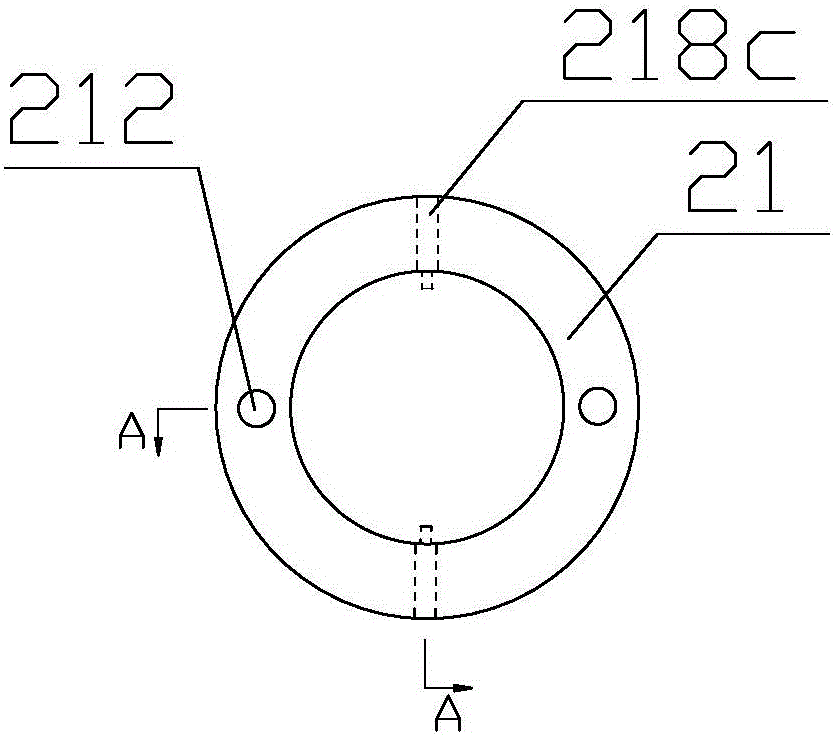

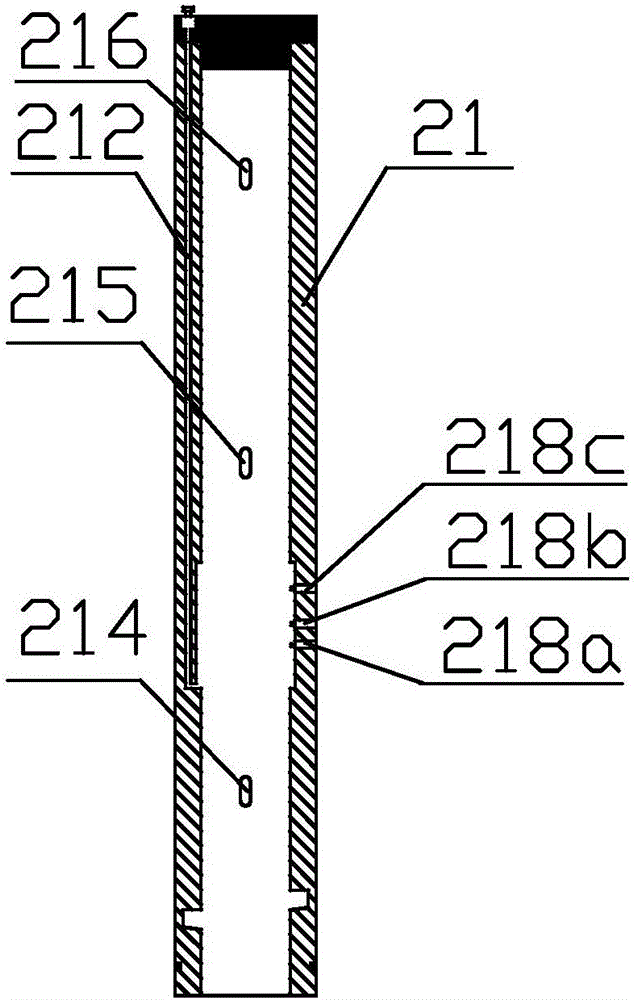

[0034]The present invention includes a cylindrical cementing equipment main body 10, and a rubber plug barrel 20 is arranged in the cementing equipment main body 10. The rubber plug barrel 20 includes a cylindrical body 21 with a closed upper end, and the cylindrical body 21 is provided with a The inner sliding sleeve 22 is in sealing contact with the inner wall of the cylinder body 21. An annular space A for liquid circulation is formed between the cylinder body 21 and the main body 10 of the cementing equipment. The air passage 212, the air flow in the air inlet passage 212 pushes the inner sliding sleeve 22 to slide upward along the axial direction of the cylinder 21, and the inner sliding sleeve 22 is installed with an upper rubber plug 24a and a lower rubber plug 24b, Located on the outer wall of the lower port of the inner sliding sleeve 22, the inner wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com