A split-type plunger steel wire drainage device

A liquid drainage device, split technology, applied in the direction of wellbore/well valve device, production fluid, wellbore/well components, etc., can solve the problem of insufficient energy in the plunger well, and the inability of the plunger and effusion to be lifted to Wellhead and other problems to achieve the effect of ensuring service life, preventing twisting, and high drainage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

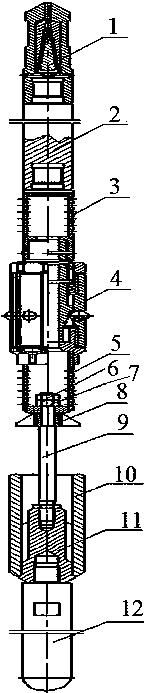

[0026] This embodiment provides a figure 1 The shown split plunger wire drainage device is divided into upper and lower parts. The upper part includes a wire rope connector 1, an upper weighting rod 2, an upper screen tube 3, a damper 4, The lower screen tube 5, the lower part includes a fin ring 8, a coupling rod 9, a plunger and a lower weighting rod 12, the upper end of the coupling rod 9 is connected to the lower screen tube 5 after passing through the fin ring 8, and the plunger includes a column The plug sleeve 10 and the plunger rod 11, the lower end of the plunger sleeve 10 is sealed after being connected with the lower end of the plunger rod 11, the lower end of the connecting rod 9 is inserted into the plunger sleeve 10 and connected to the upper end of the plunger rod 11, the column The lower end of the plug rod 11 is connected with the lower weighting rod 12 , the outer diameter of the plunger sleeve 10 is smaller than the inner diameter of the oil pipe, and the de...

Embodiment 2

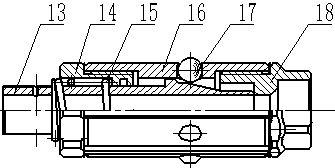

[0035] On the basis of Embodiment 1, this embodiment provides a split-type plunger wire drainage device. The lower screen tube 5 is a metal cylinder with holes on the wall of the cylinder, and the lower end is fixedly connected with an external thread. The plug, the central position of the plug is provided with a circular hole, the upper end of the connecting rod 9 passes through the circular hole, and is connected with the lower screen tube 5 through the bearing nut 7 and the back cap 6, seefigure 1 .

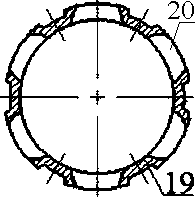

[0036] The connecting rod 9 is divided into two sections by a small upper shoulder and a large lower shoulder. The fin ring 8 is composed of three triangular metal plates evenly distributed on the outer wall of the cylinder and the cylinder. The fin ring 8 is sleeved on the connecting rod 9. The upper end is clamped between the lower end face of the lower screen tube 5 and the shoulder of the connecting rod 9 . See Figure 4 shown.

[0037] The outer diameter of the plunger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com