fan

A technology of fan and air inlet ring, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc. It can solve the problems of ineffective collection, affecting the cleaning of the fan and the external environment, and affecting the filtering effect of the fan, so as to achieve a good oil filtering effect , keep clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

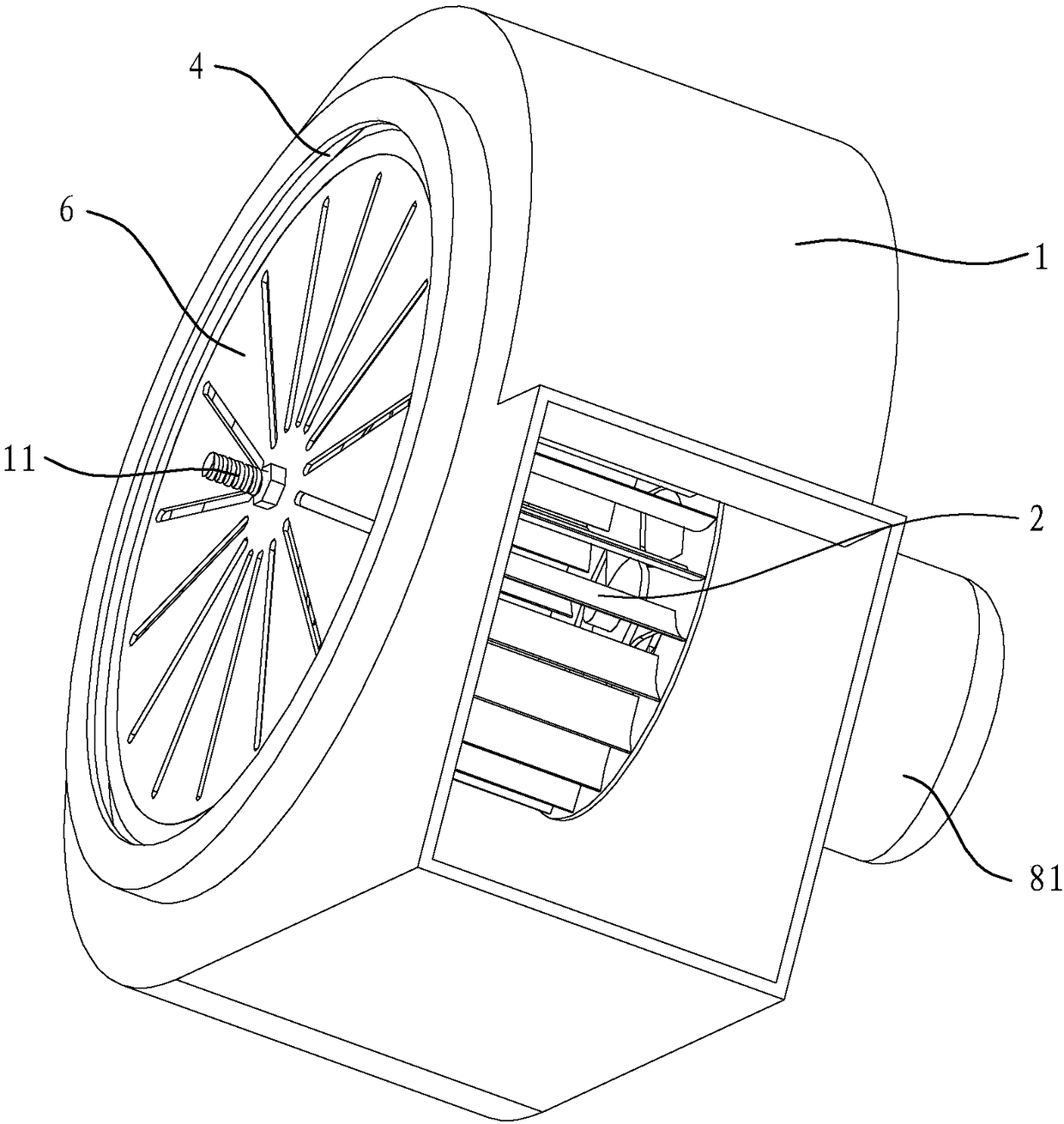

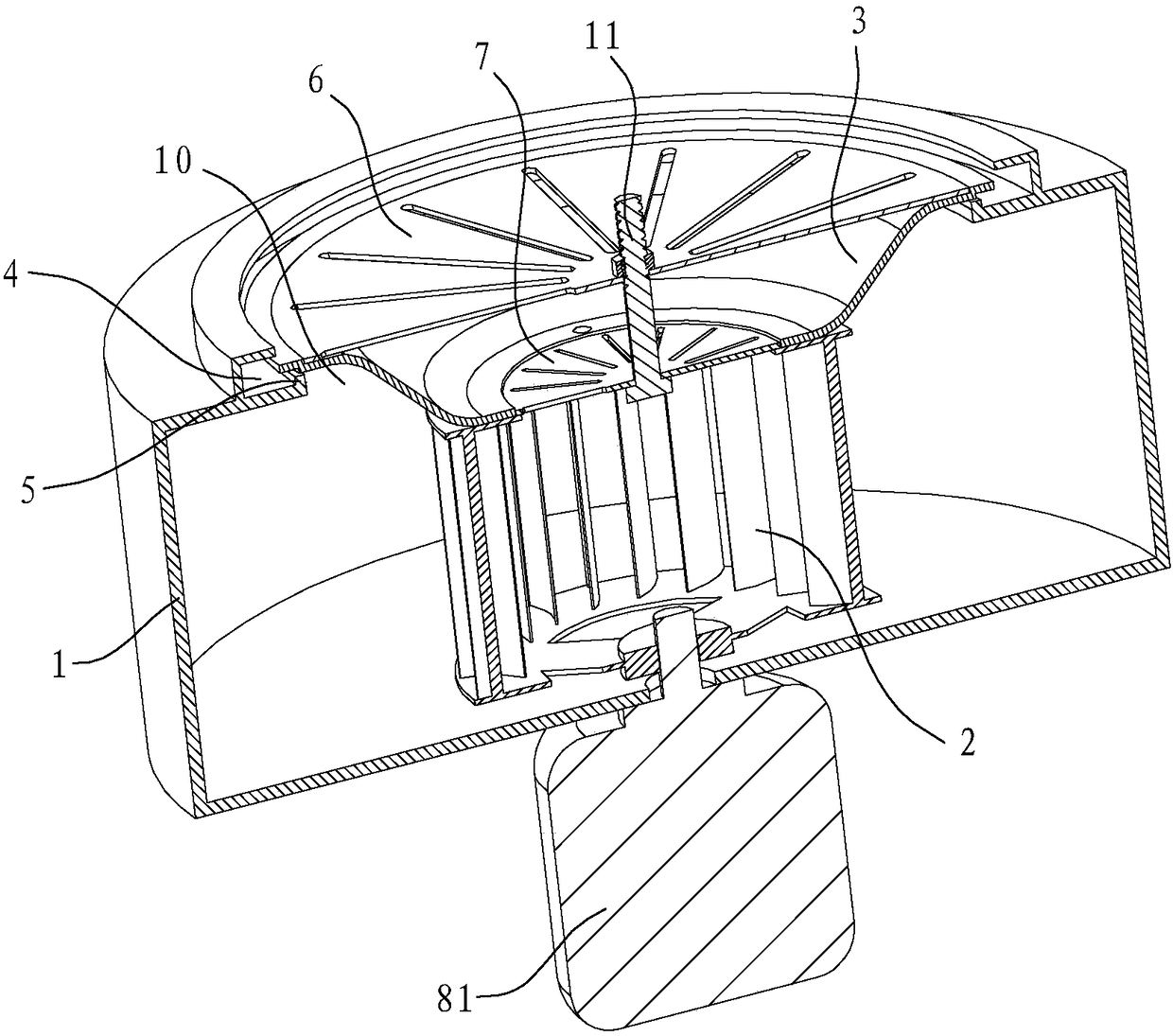

[0021] like figure 1 and figure 2 As shown, the fan in this embodiment includes a volute 1, an impeller 2 and an air inlet ring 3, the impeller 2 is installed inside the volute 1, the fan has an air inlet 10, and the air inlet ring 3 is located at the air inlet 10 In addition, the air inlet ring 3 is installed on the impeller 2 and can rotate synchronously with the impeller. There is a gap between the outer periphery of the air inlet ring 3 and the corresponding side wall of the volute 1. An oil filter pan that can rotate synchronously with the air intake ring. A first driving motor 81 is installed on the outer wall of the volute opposite to the air inlet ring 3 , and the impeller 2 is installed on the driving shaft of the first driving motor 81 .

[0022] In this embodiment, an oil receiving groove 4 is provided on the side wall of the volute 1 corresponding to the air inlet ring 3, and the oil receiving groove 4 is arranged around the air inlet 10 of the fan and has a rad...

Embodiment 2

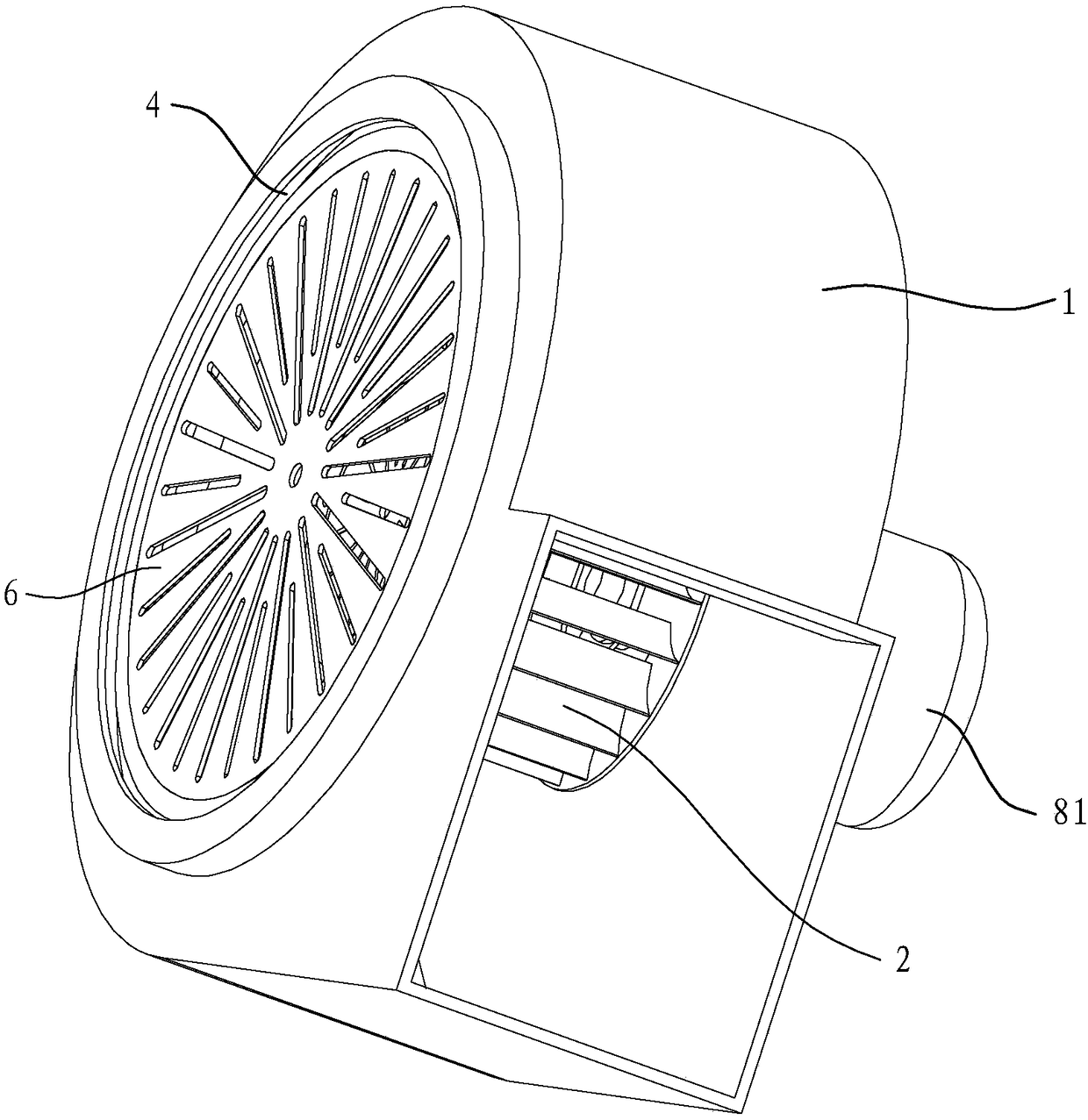

[0026] like image 3 and Figure 4 As shown, the outer oil filter pan 6 in the fan in this embodiment is fixed on the outer peripheral edge of the air inlet ring 3, the inner oil filter pan 7 is fixed on the inner peripheral edge of the air inlet ring 3, and the outer oil filter pan 6 and the inner side The oil filter pans 7 are not connected by a connecting shaft 11, and the rest of the structure is the same as that in Embodiment 1, and will not be further described here.

Embodiment 3

[0028] like Figure 5 As shown, the fan in this embodiment has two air inlets 10 arranged opposite to each other in the axial direction, and there are two air inlet rings 3, each air inlet ring 3 is arranged on the air inlet 10 on the corresponding side, and a drive is installed inside the fan The second drive motor 82 for the rotation of the impeller 2, and the two air inlet rings 3 are installed on the impeller 2 and can rotate synchronously with the impeller. In addition, fixed brackets 9 are installed on both outer walls of the volute 1 , and the drive shaft of the second drive motor 82 passes through the corresponding side of the air inlet ring 3 and is rotatably mounted on the corresponding side of the fixed brackets 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com