Production line for compound potato chips

A production line and potato chip technology, applied in the field of compound potato chip production line, can solve the problems of difficult control of powder spraying amount, poor oil filtering effect, and influence on potato chip products, and achieve good oil filtering effect, good material spreading effect, and efficient processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

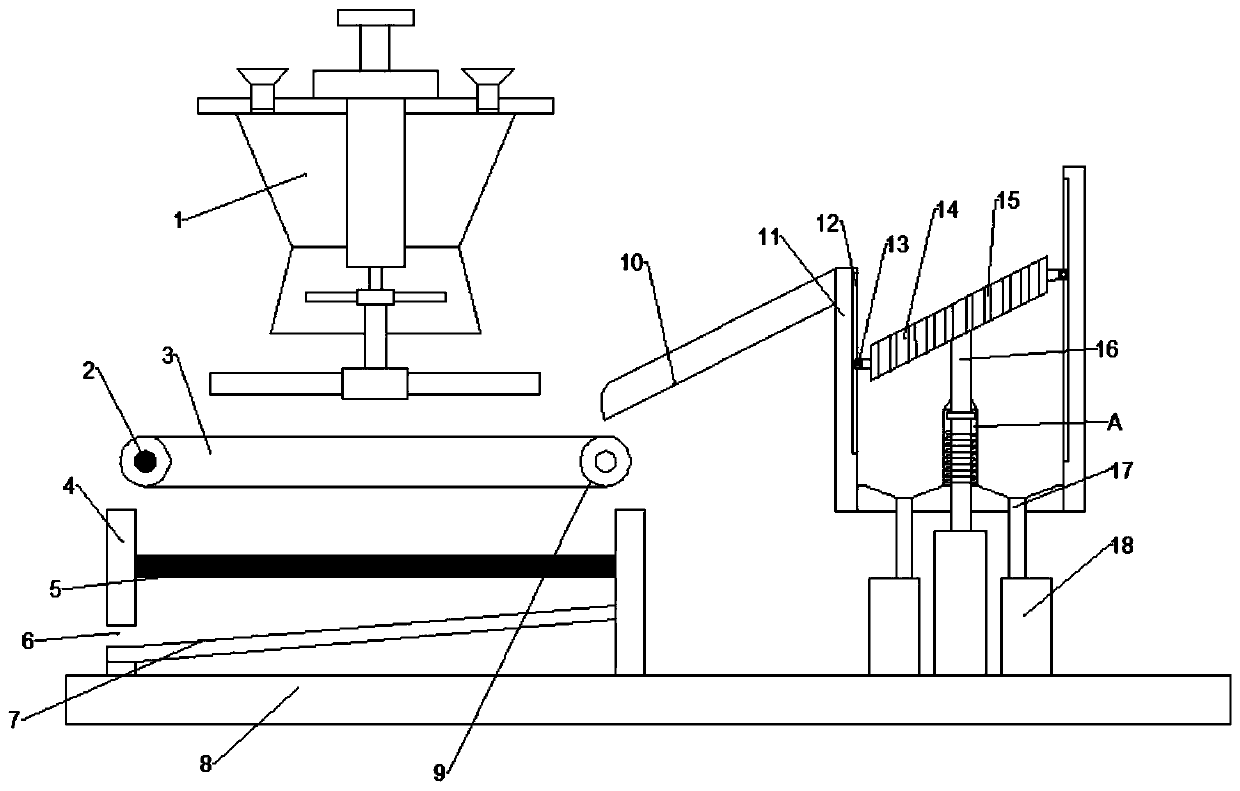

[0025] see figure 1 , in Embodiment 1 of the present invention, a composite potato chip production line includes: a powder spreading device, an oil filtering device and a base 8, the powder spreading device is arranged on the left side of the base 8, and the oil filtering device is installed and fixed on the right side of the base 8, The powder spreading device and the oil filtering device are connected through a material guide plate 10;

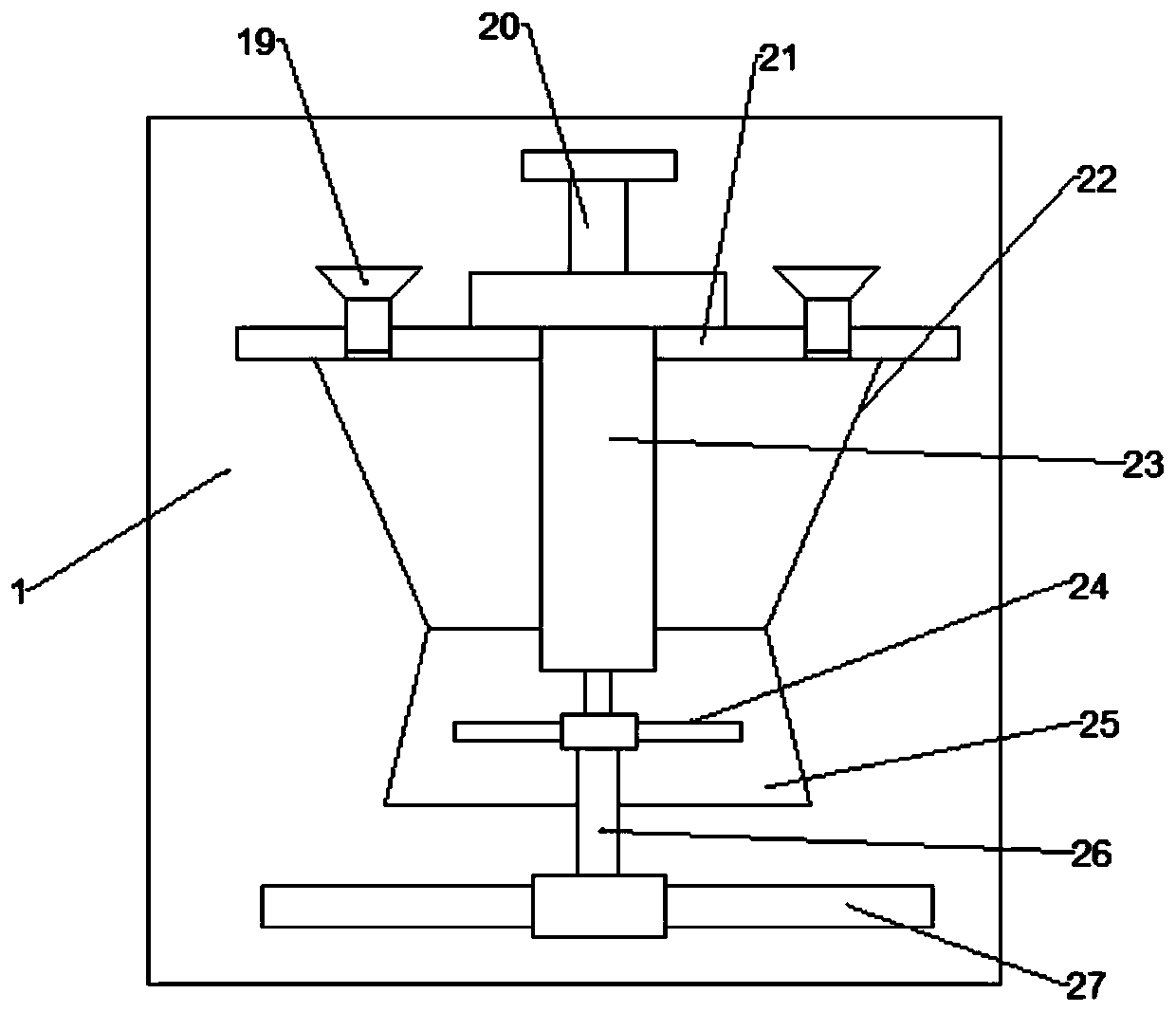

[0026] The powder spreading device includes a powder spreading assembly 1 and a recovery assembly. The powder spreading assembly 1 is installed on the upper end of the recovery assembly. A transmission assembly is arranged between the powder scattering assembly 1 and the recovery assembly. The upper right end of the transmission assembly is facing the left side of the material guide plate 10 The lower end of the side; the oil filter device includes a storage box 11, and an oil filter assembly is movably installed inside the storage box 11. ...

Embodiment 2

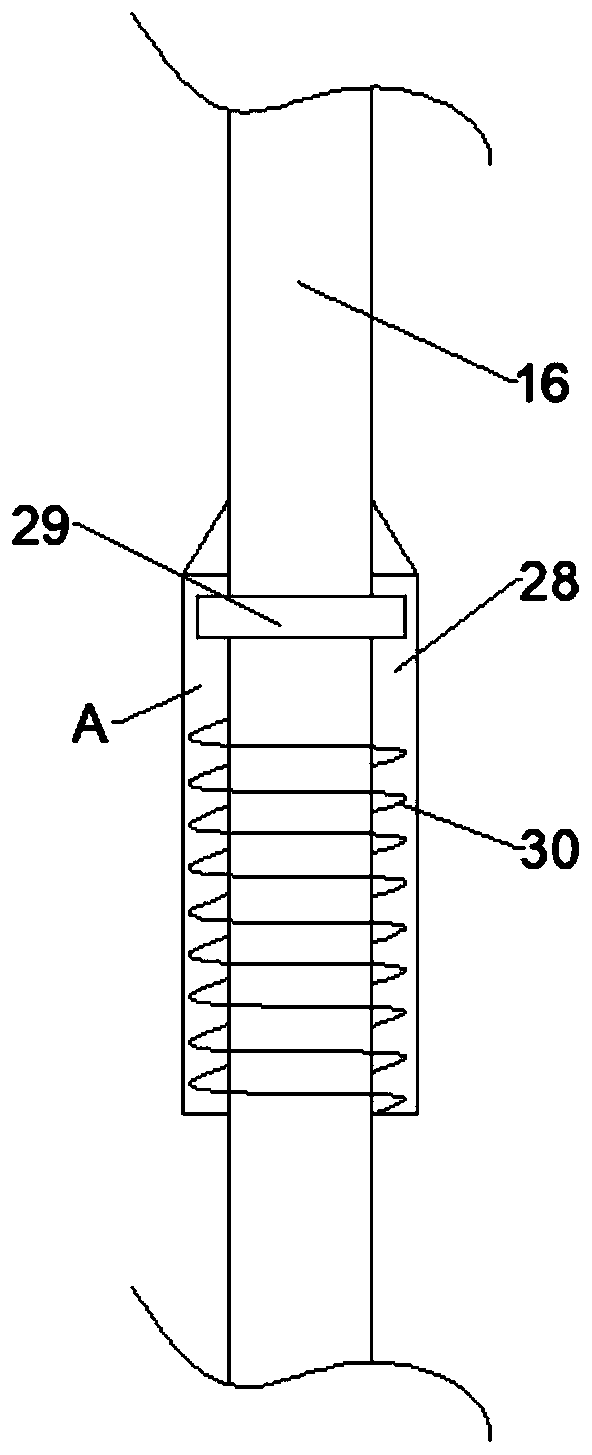

[0034] Further, the oil filter assembly includes a movable plate 14, the movable plate 14 moves up and down inside the material storage box 11 through the electric telescopic rod 16, and an oil leakage hole 15 is opened inside the movable plate 14, and the oil leakage hole 15 is used for oil leakage Pulley 13 is installed on movable plate 14 left and right sides, and storage box 11 inwall is provided with slide rail 12, and the pulley 13 rolling on movable plate 14 left and right sides is installed on the slide rail 12 surface of storage box 11 inside; Oil guide pipes 17 are arranged on the left and right sides of the lower end of the tank 11, and the bottom end of the oil guide pipe 17 is connected to the oil storage tank 18;

[0035] The fried potato chips fall on the movable plate 14 inside the material storage box 11, and the movable plate 14 is driven to move up and down by the electric telescopic rod 16, and then the potato chips are leaked with oil, and the leaked oil is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com