Patents

Literature

32results about How to "Improve oil filtration effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

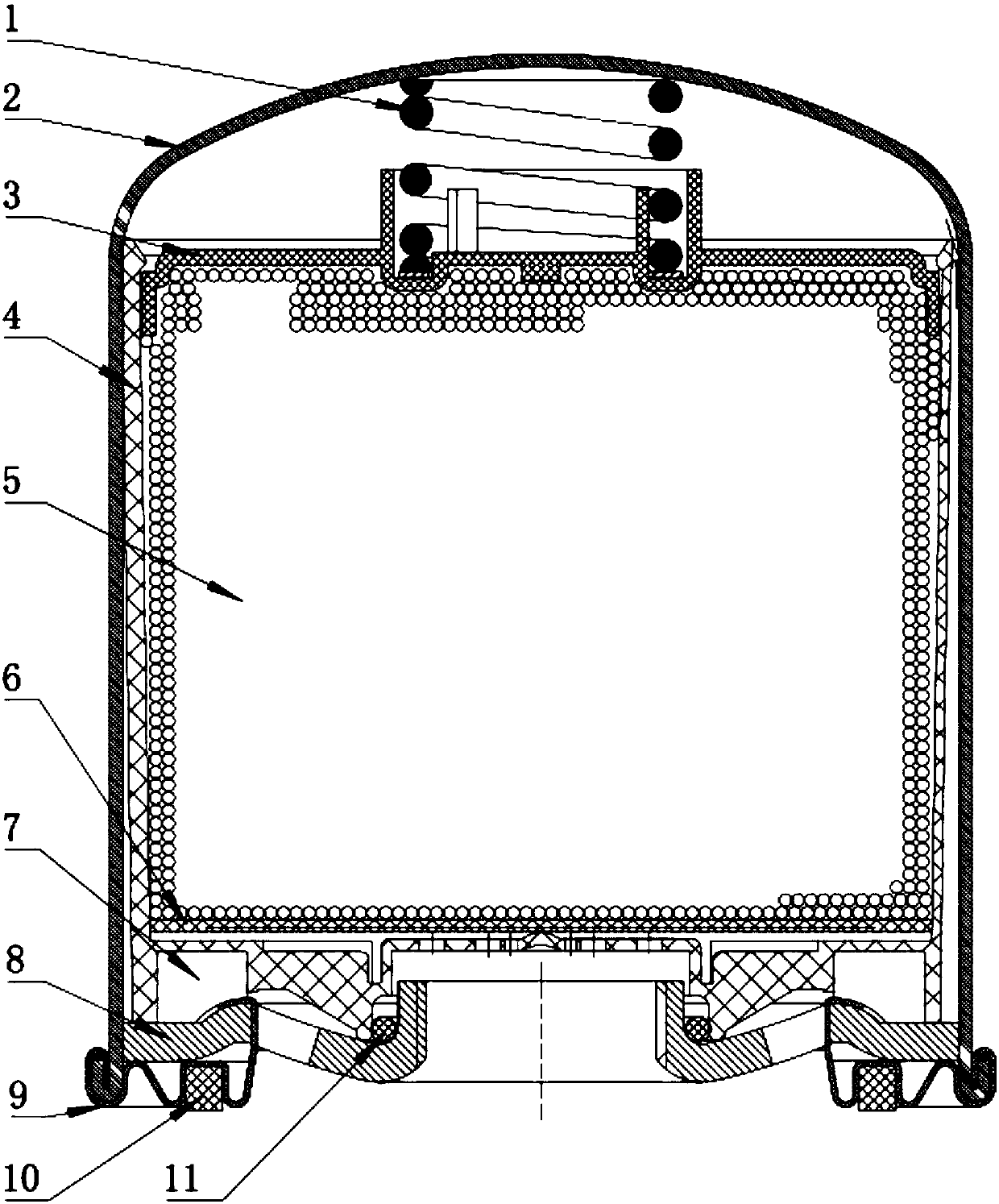

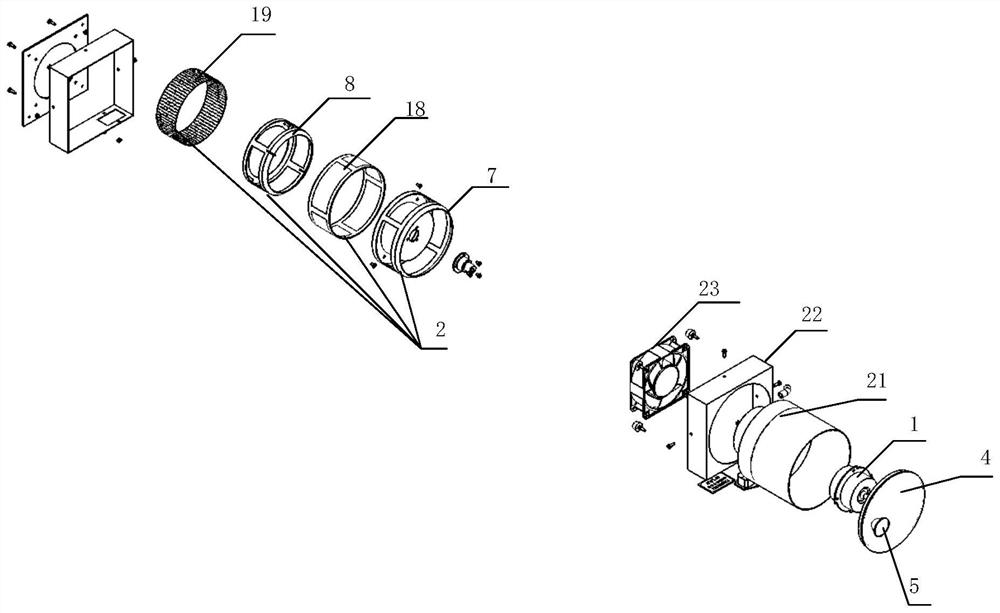

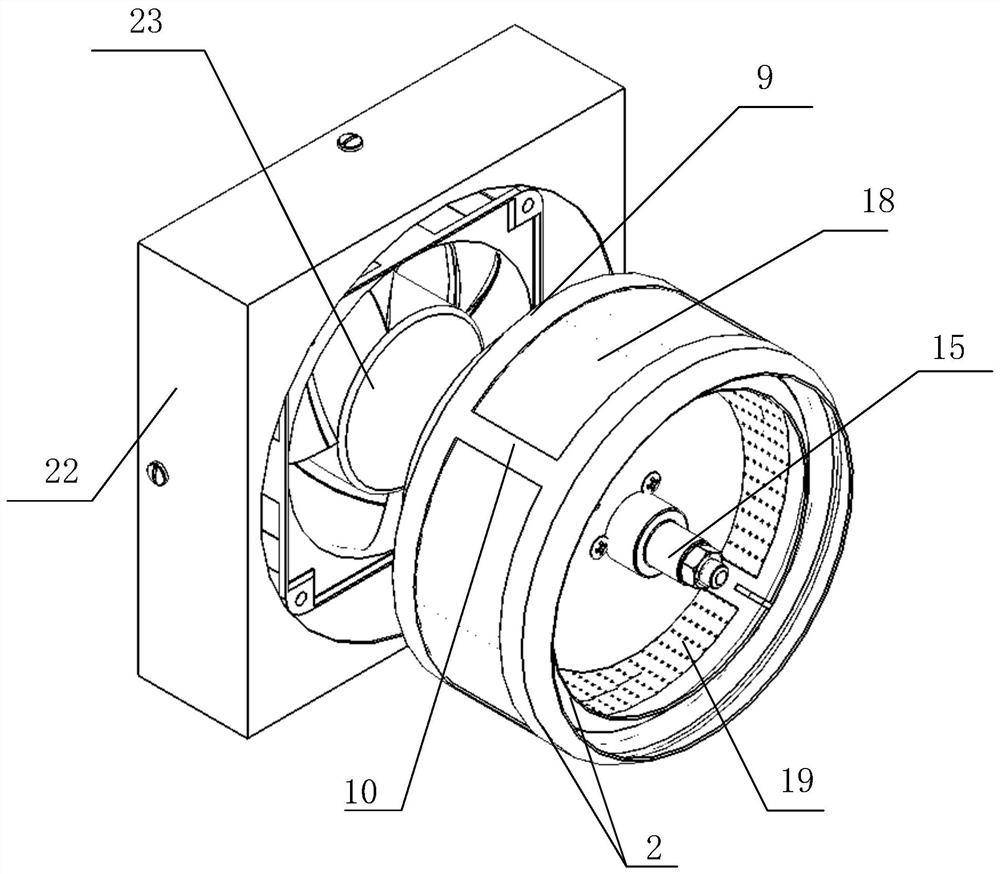

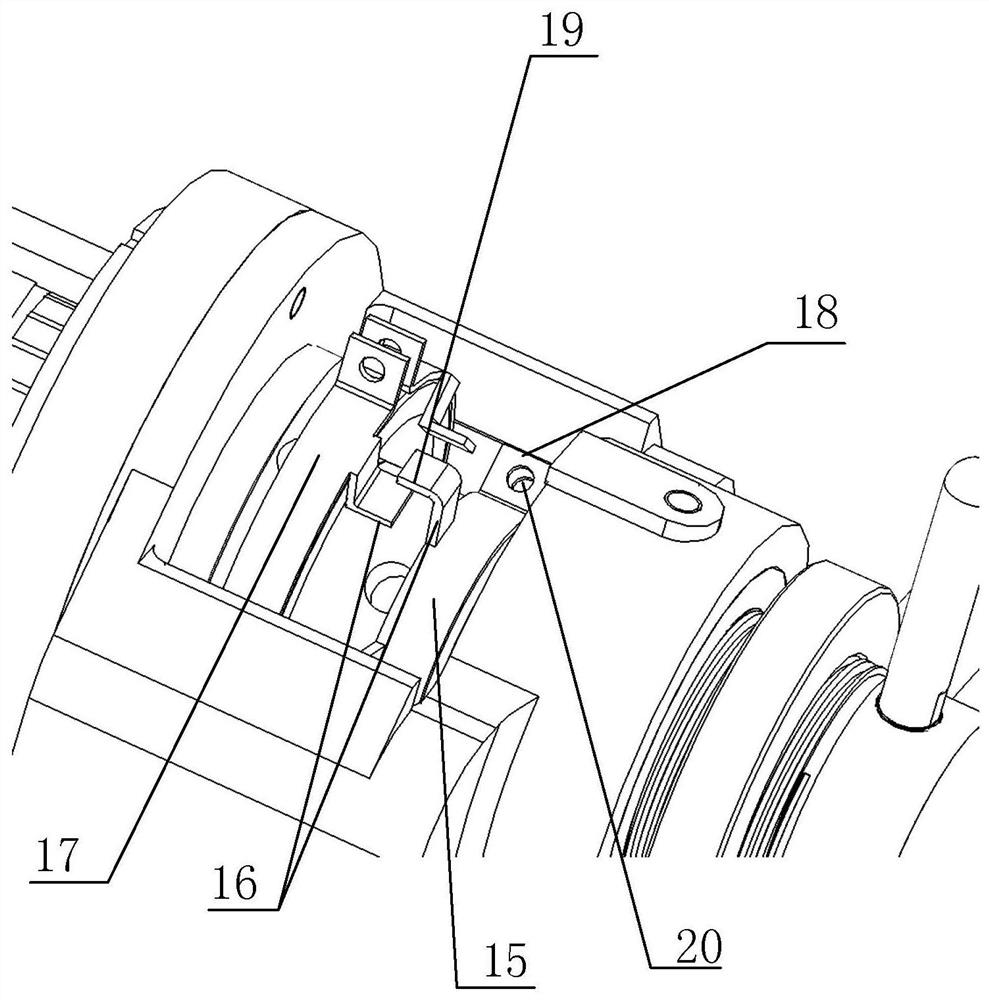

Oil Mist Filter

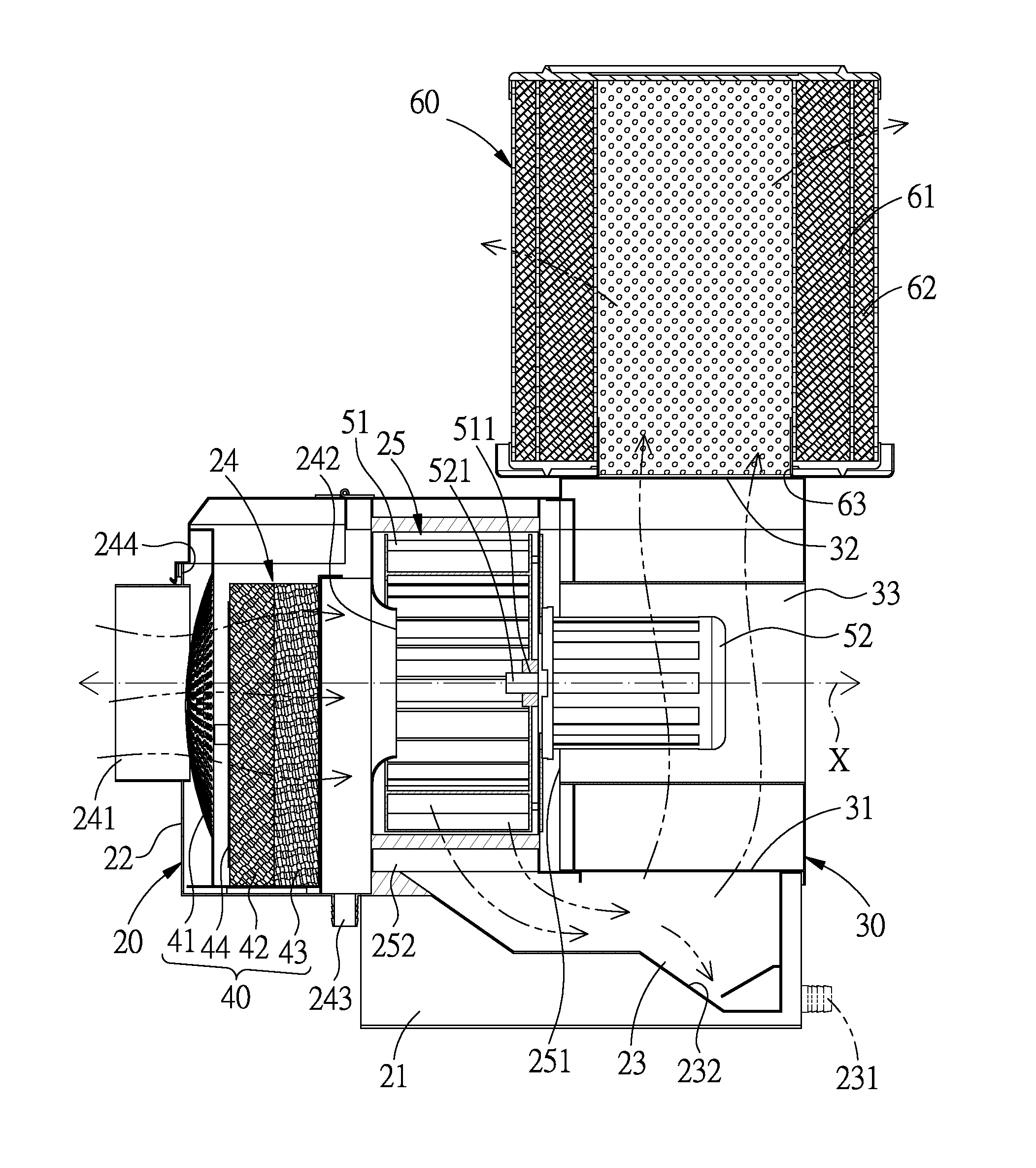

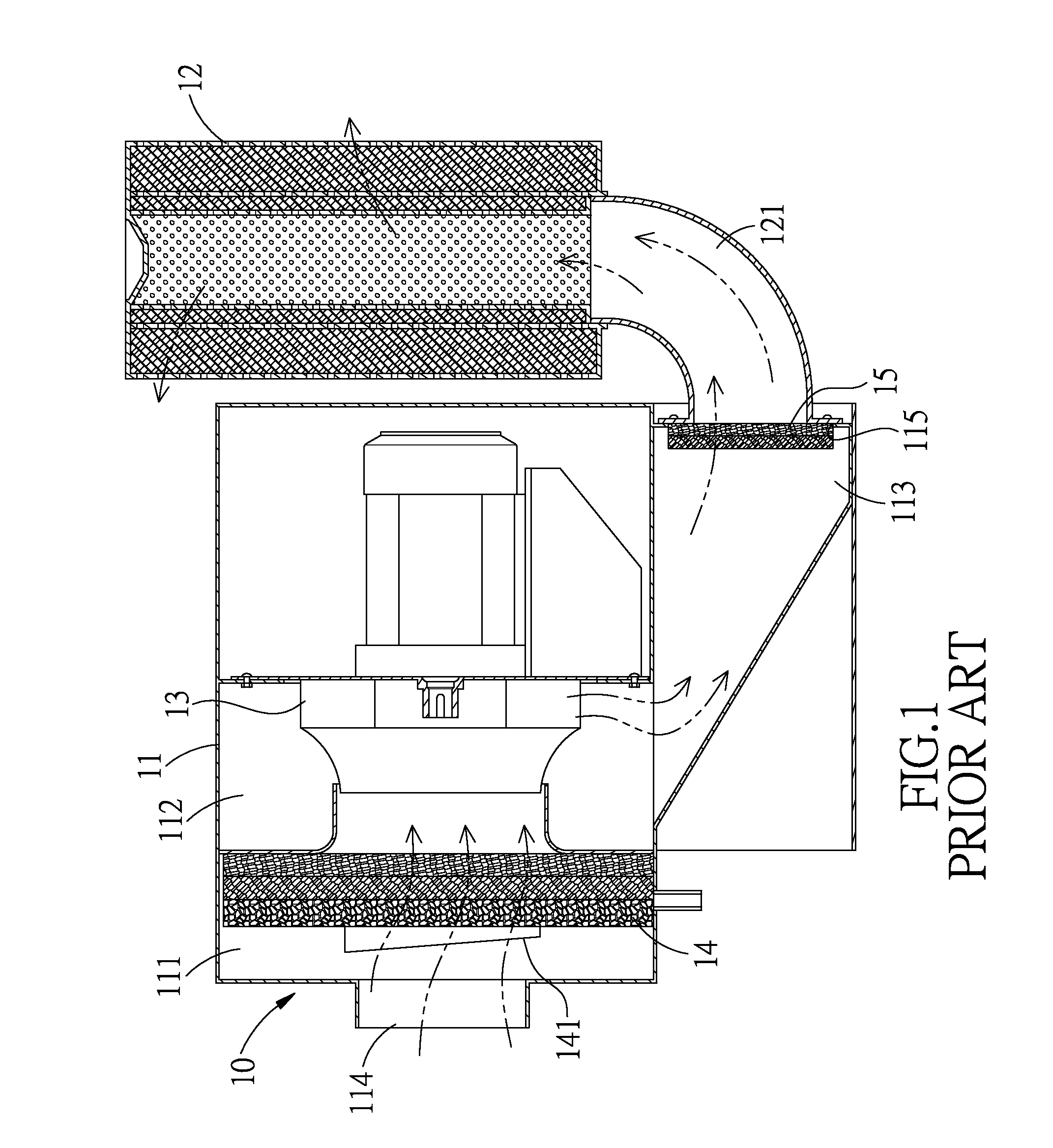

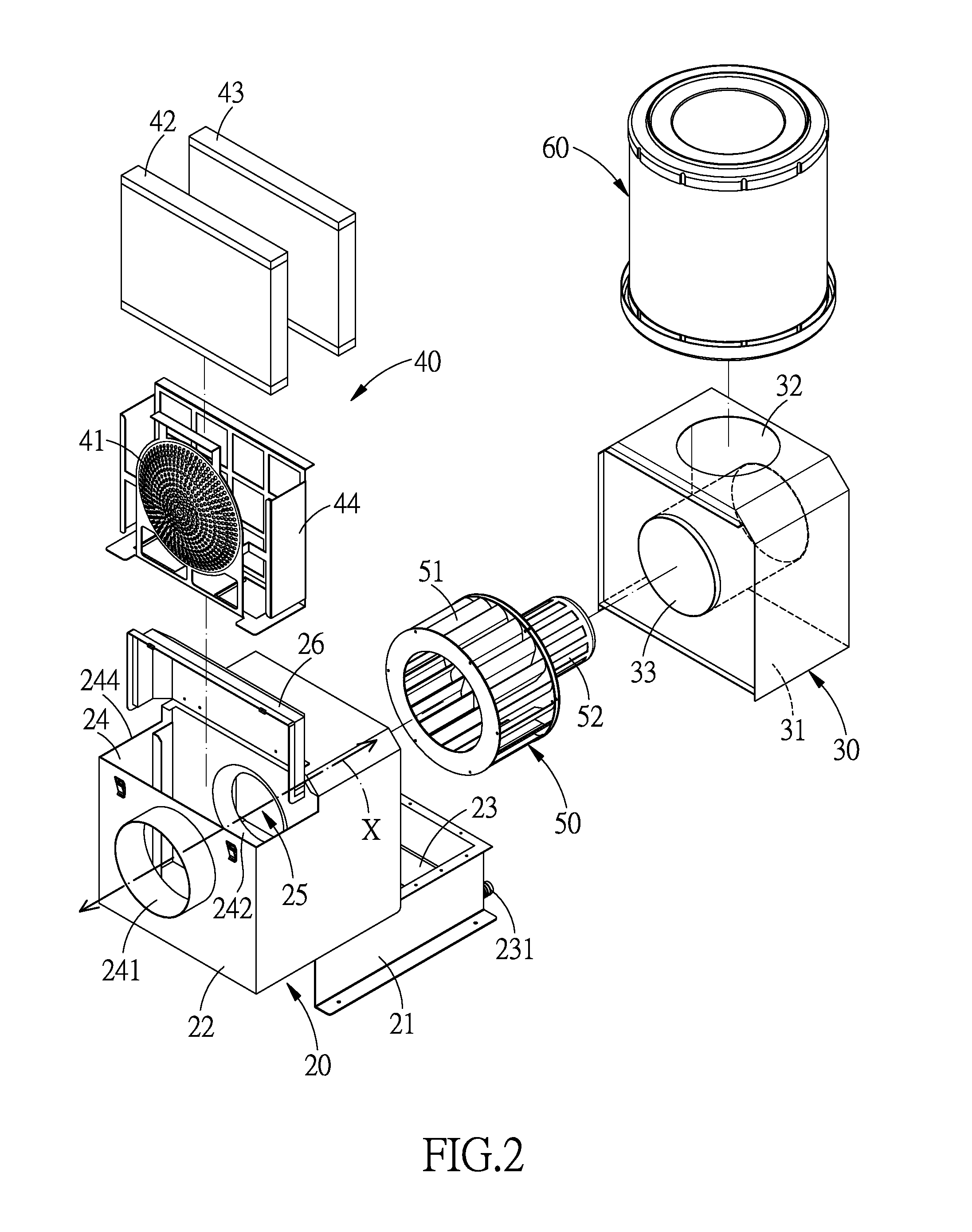

InactiveUS20130255501A1Improve oil filtration effectImprove filtering effectCombination devicesPositive displacement pump componentsWaste managementEngineering

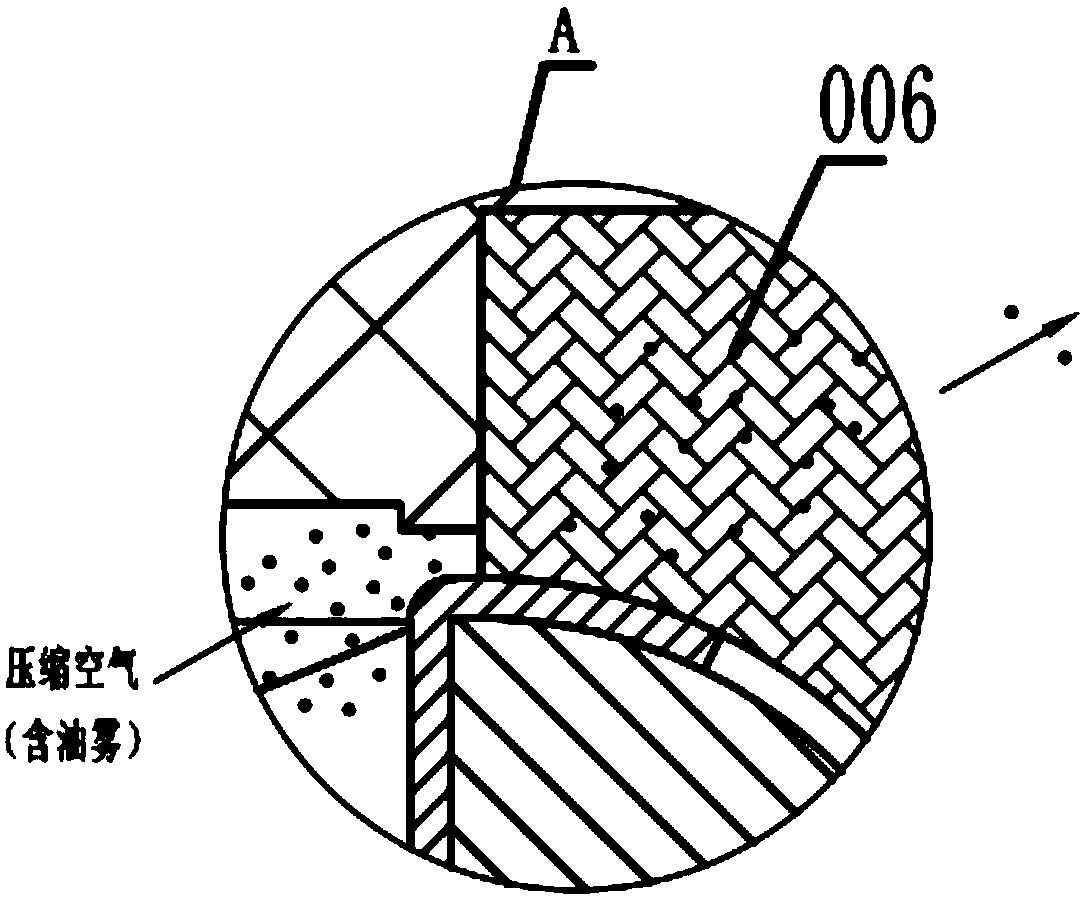

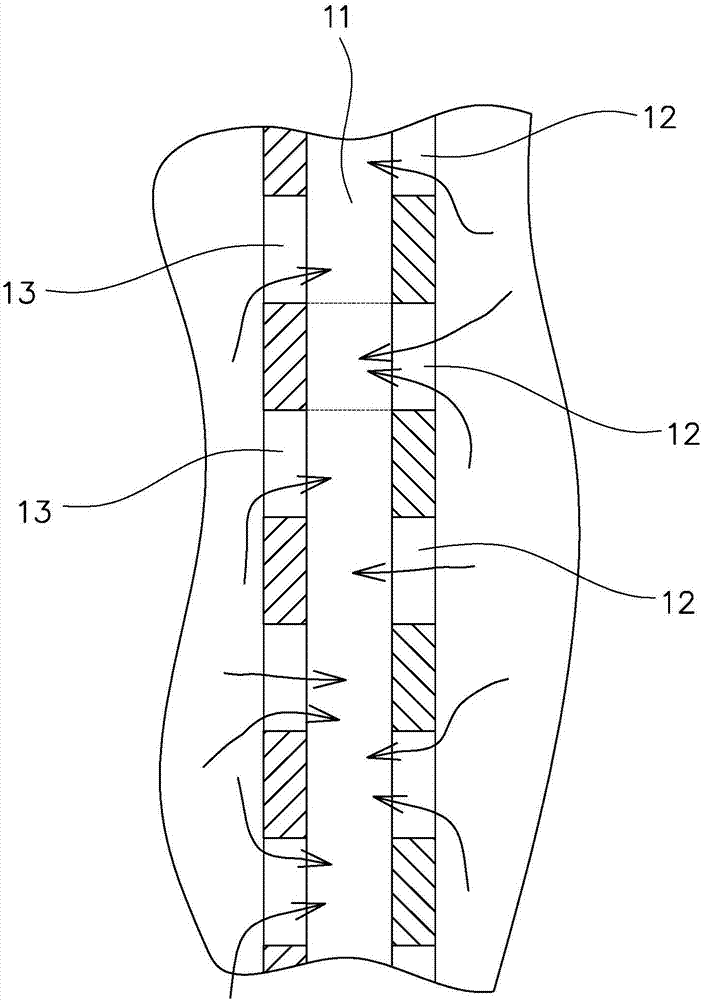

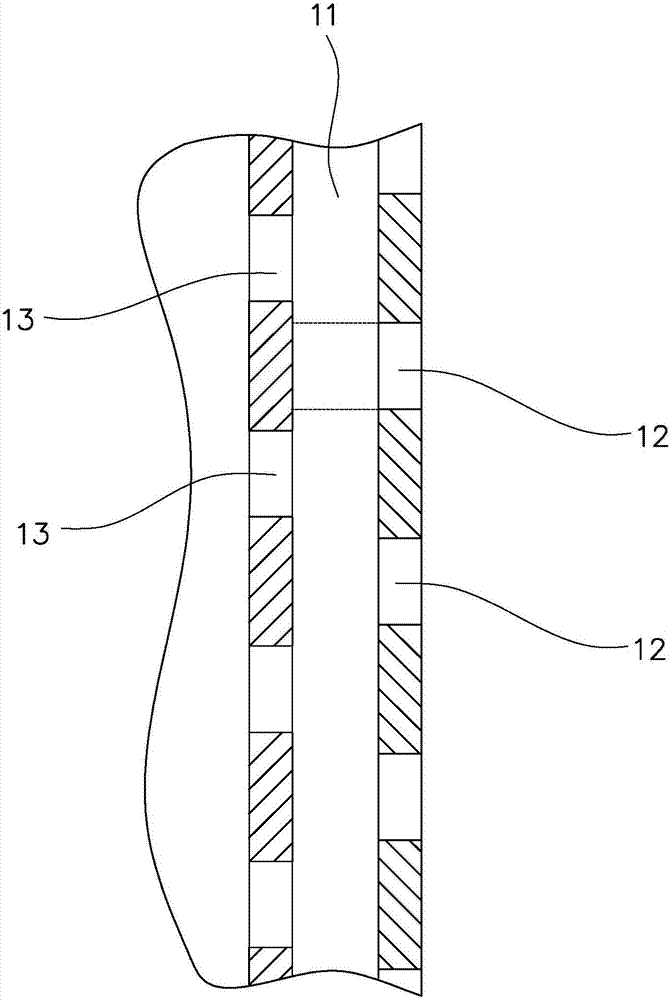

An oil mist filter is provided with a housing, a shell, a filtering assembly and a sucking mechanism which are disposed in the housing and the cover, and a filtering cylinder mounted outside the shell. The arrangement of the filtering space, the sucking space and the oil-collecting chamber inside the housing, and the interior of the shell being in communication of the filtering cylinder, changes the flow direction of the oil mist, so that the oil mist is guided to and discharged out of the filtering cylinder.

Owner:SUN WEI

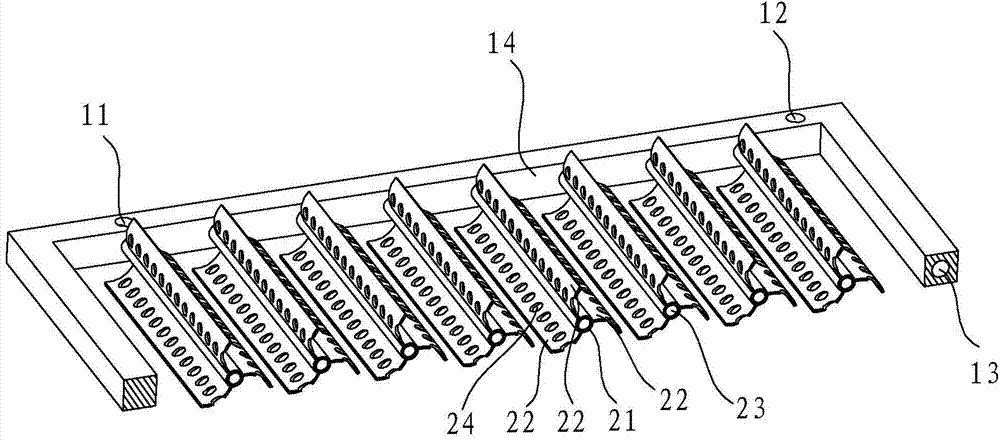

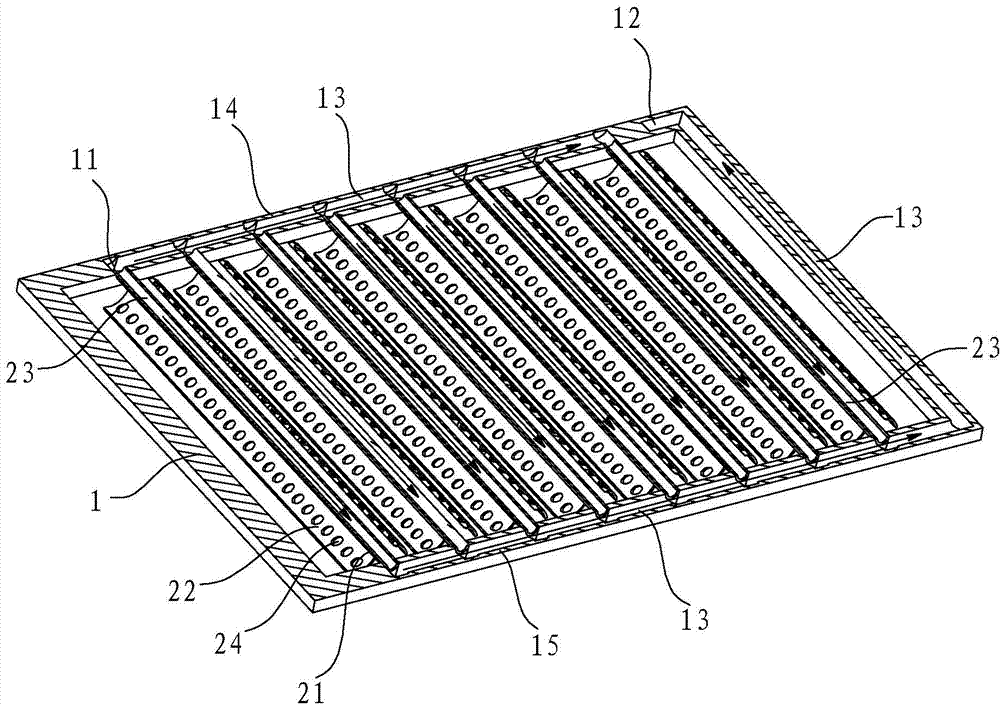

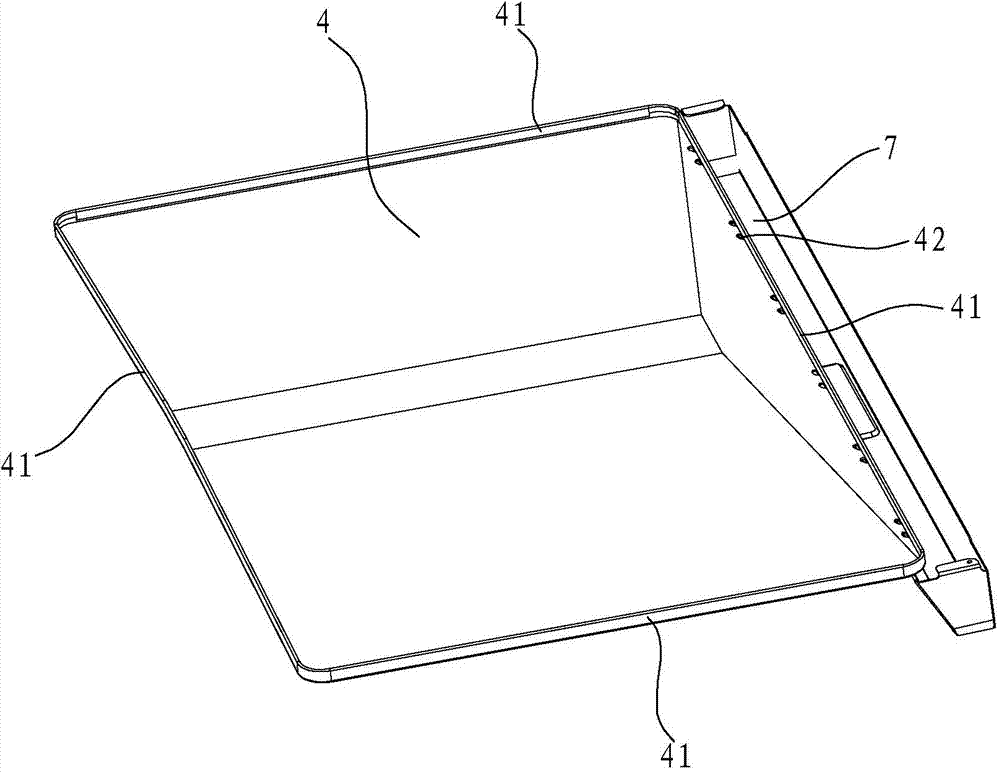

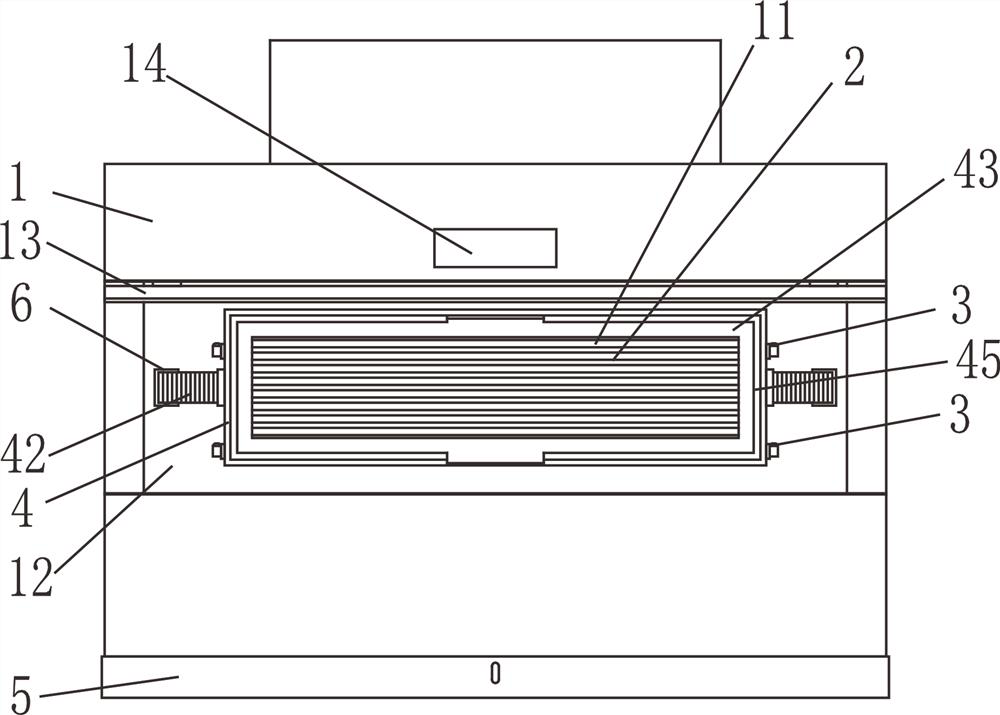

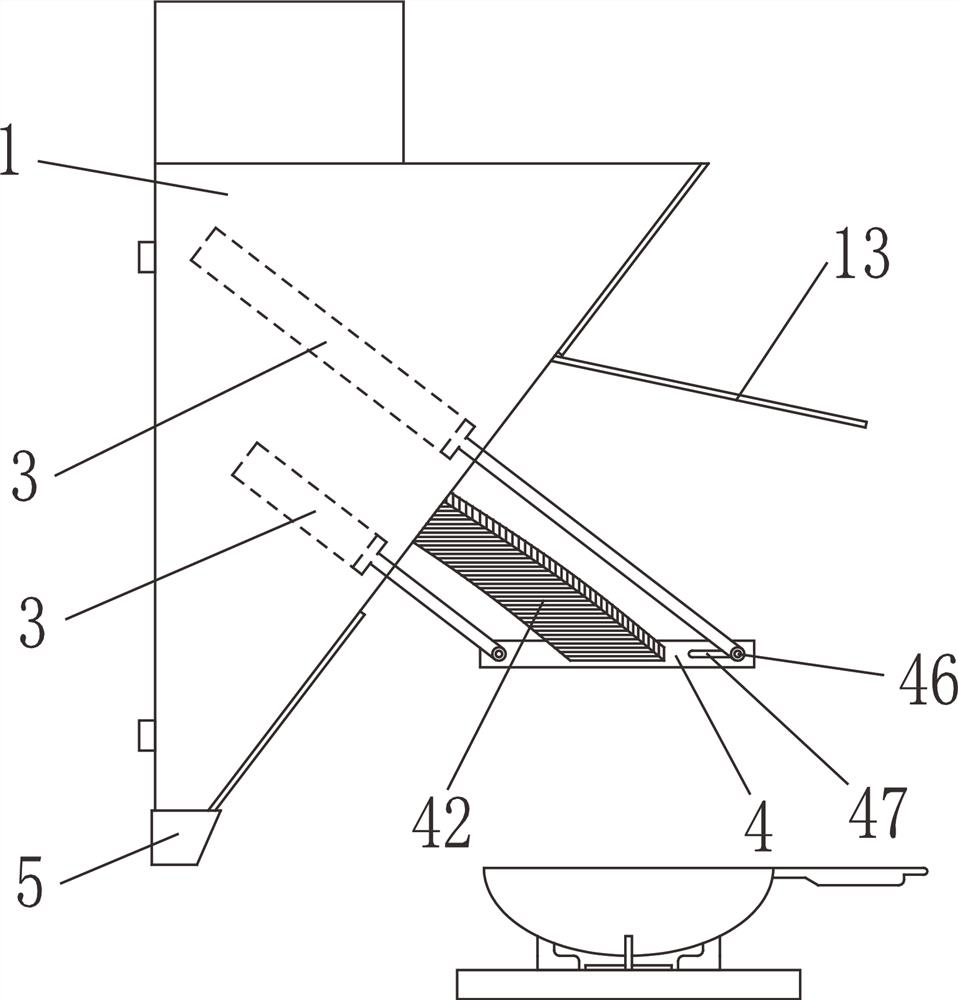

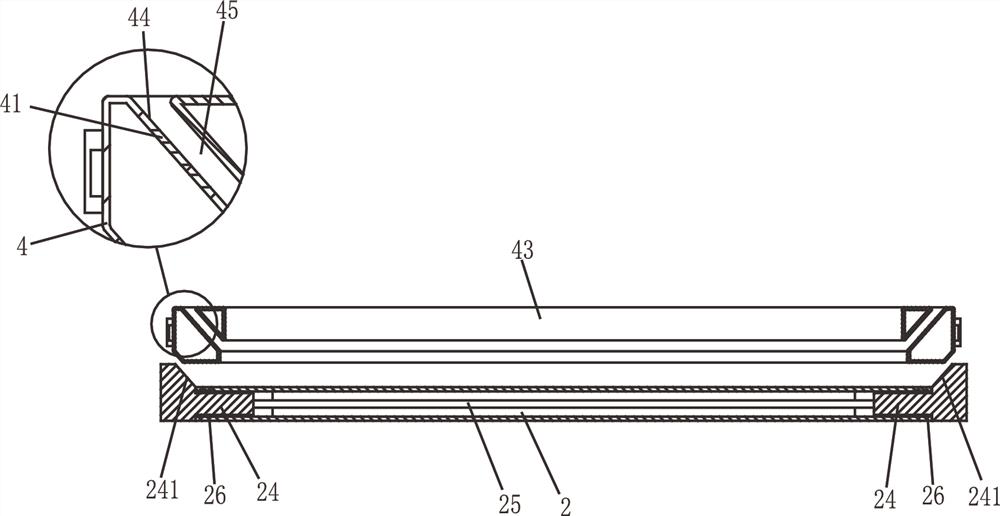

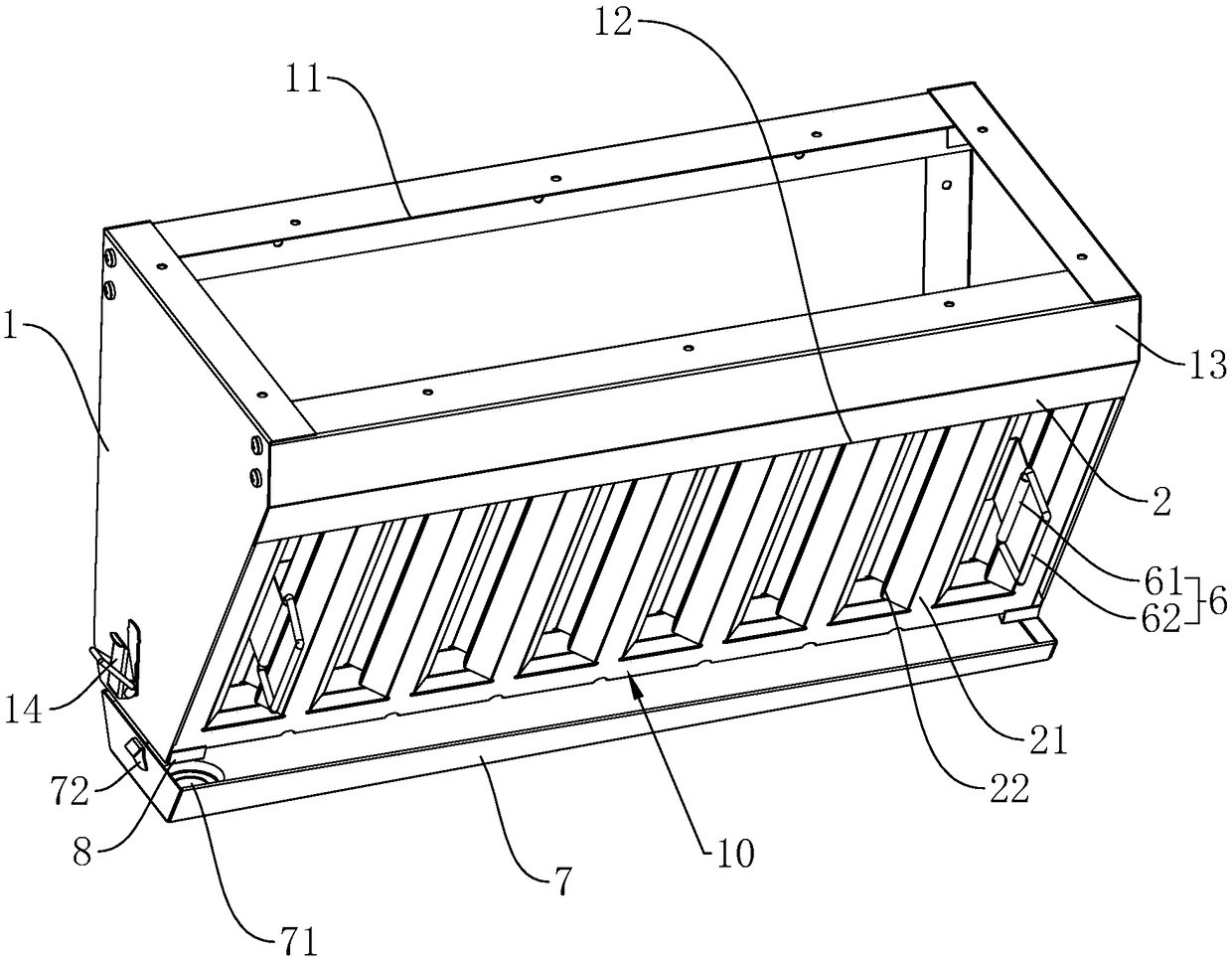

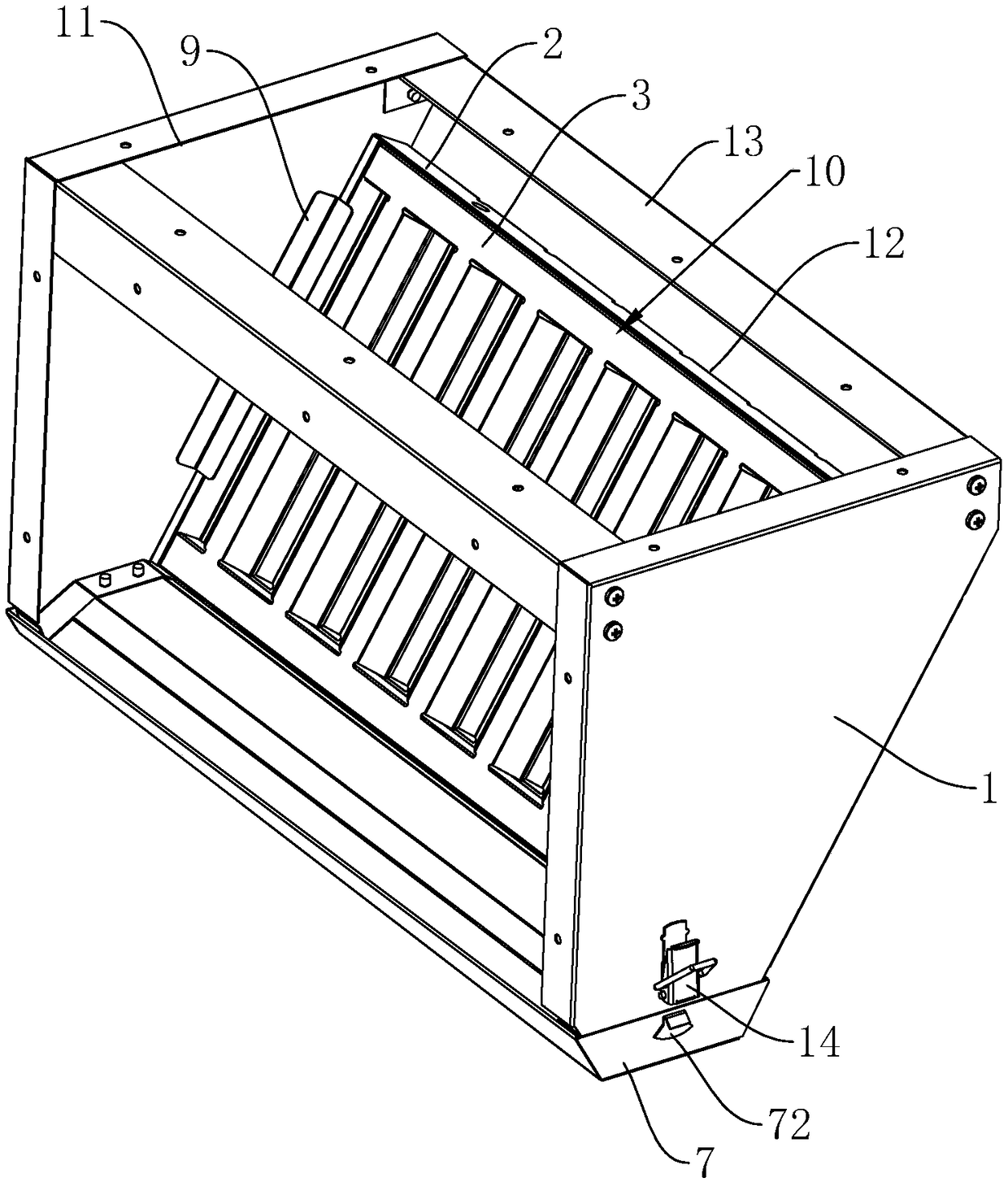

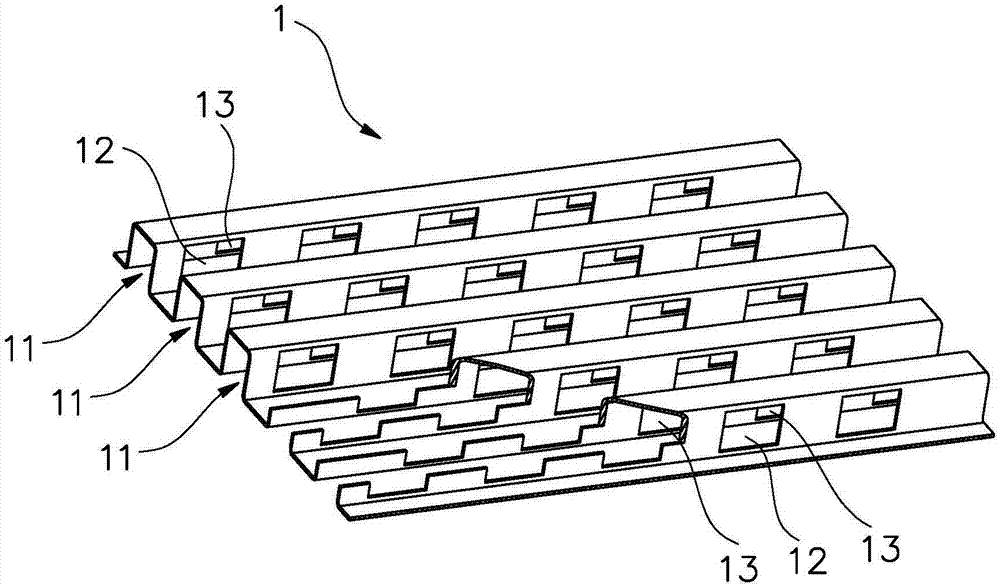

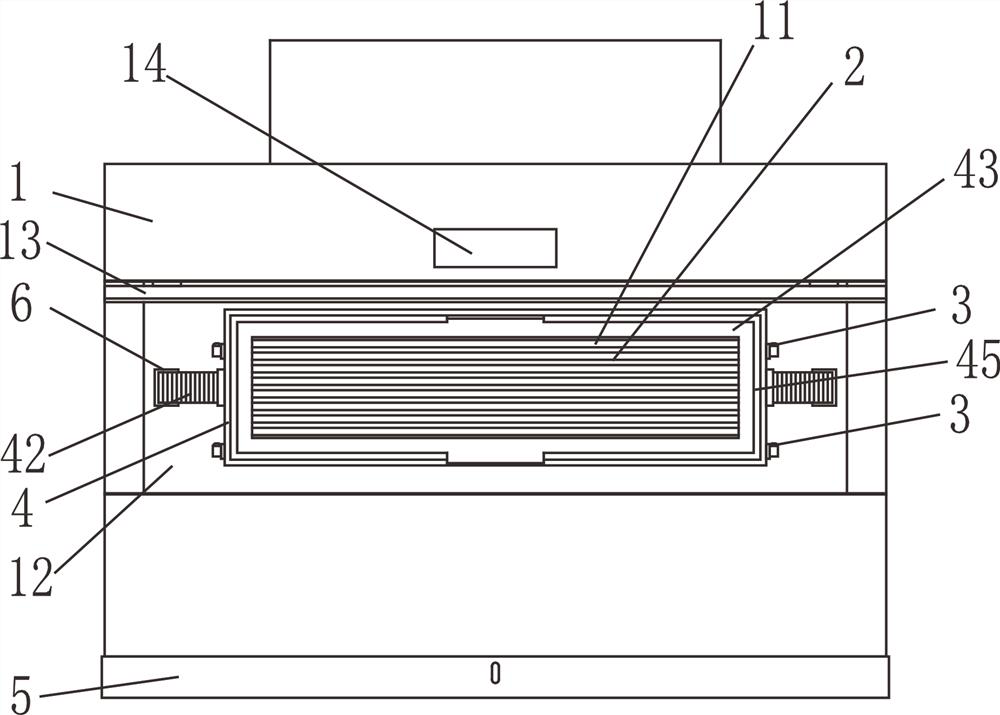

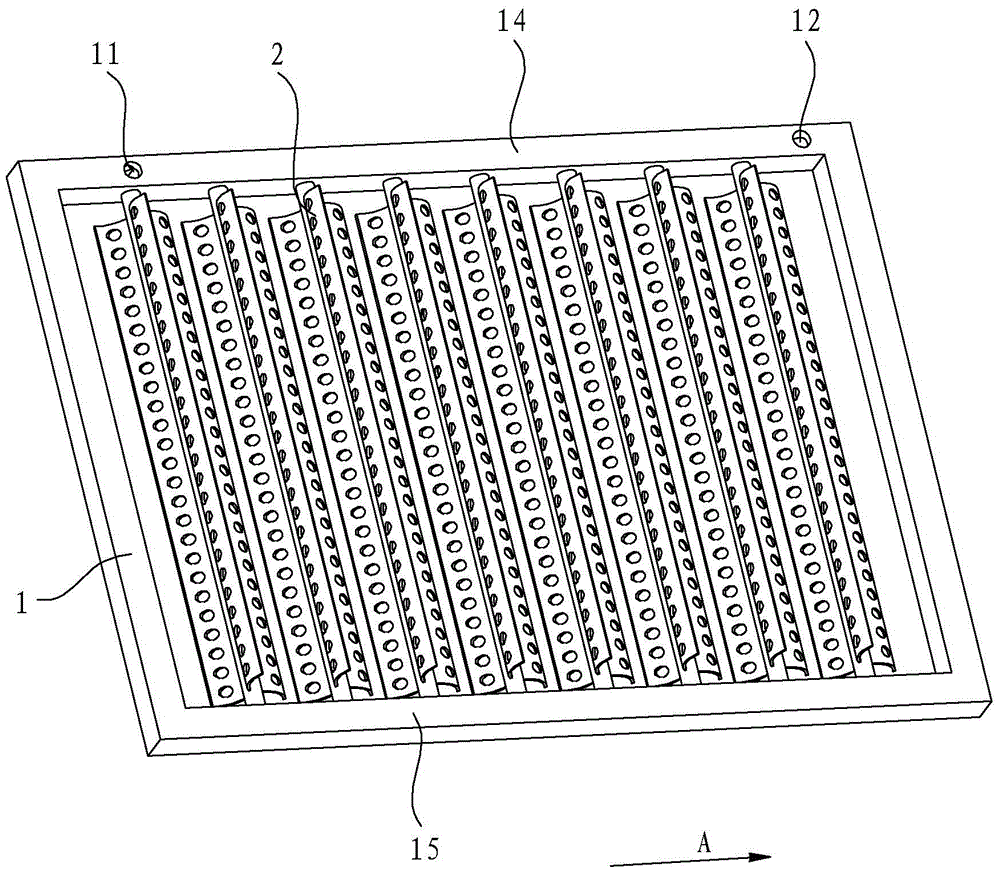

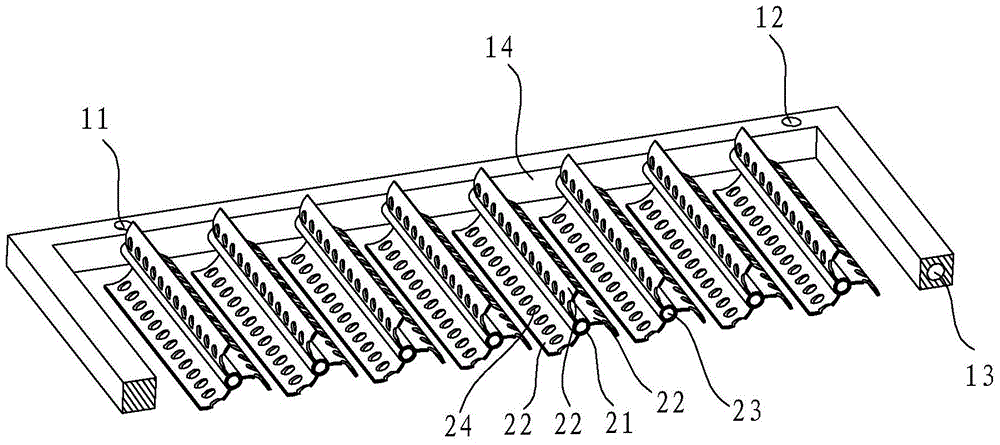

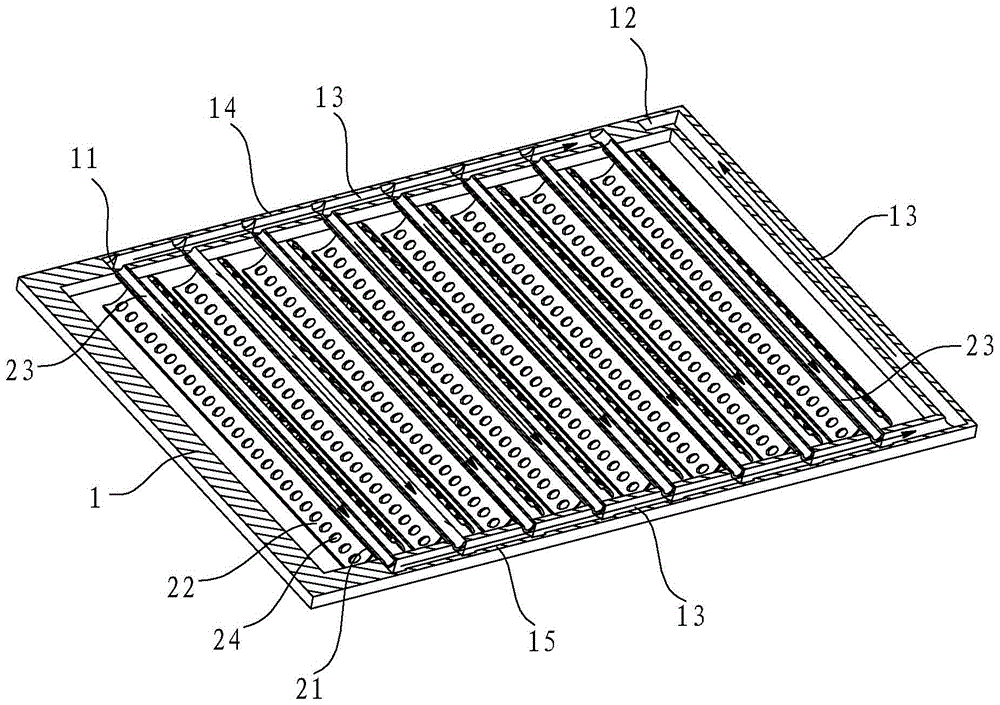

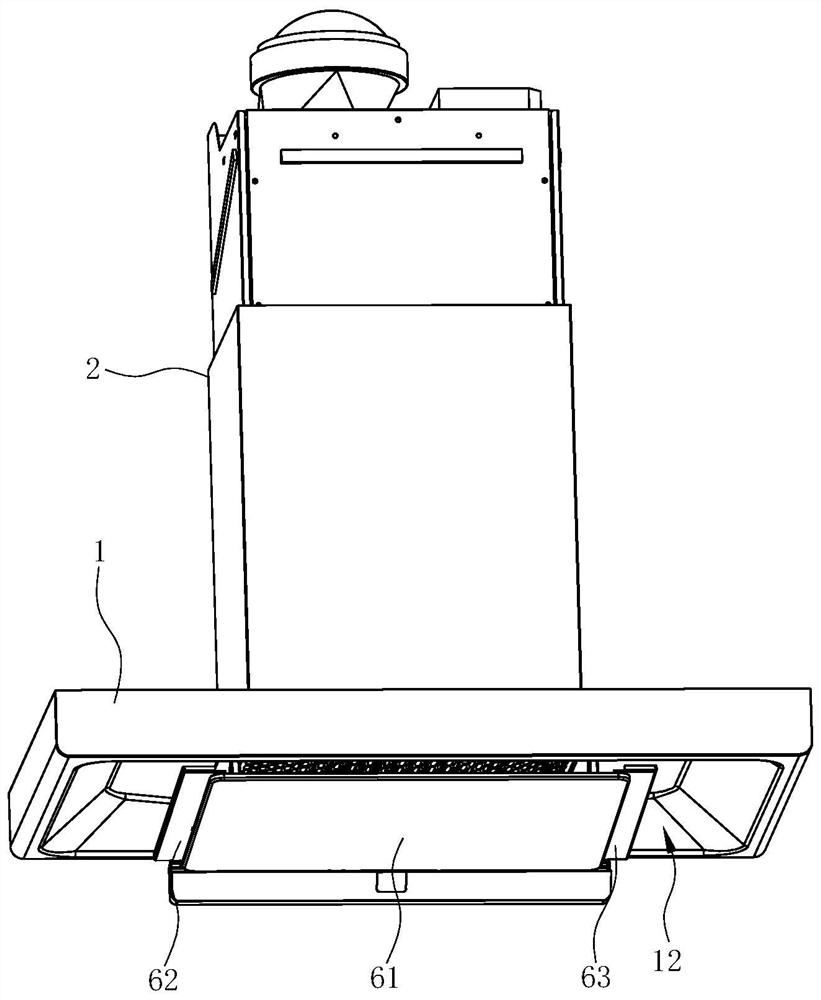

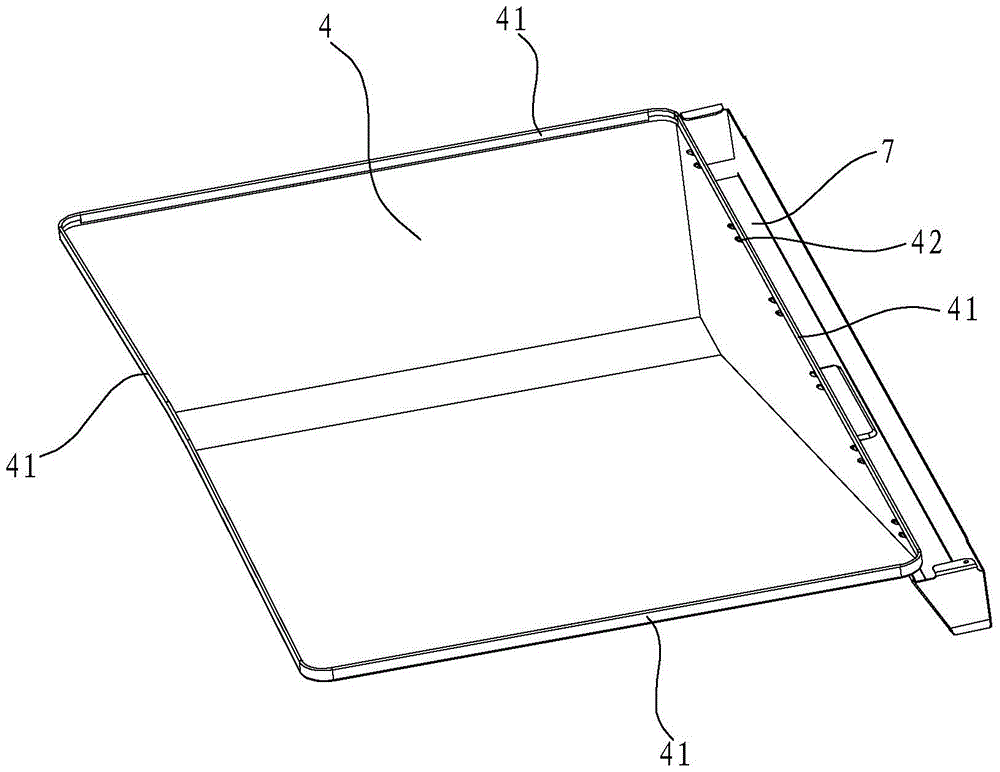

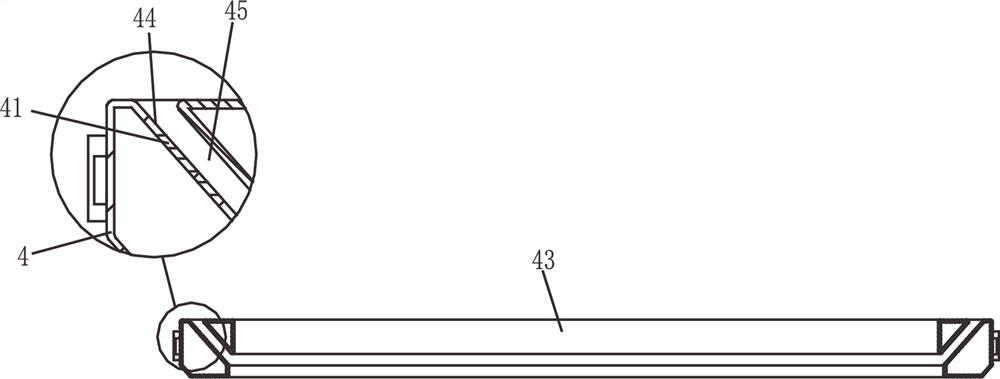

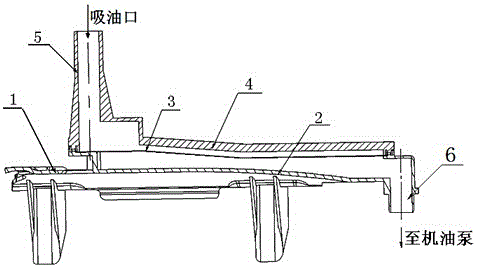

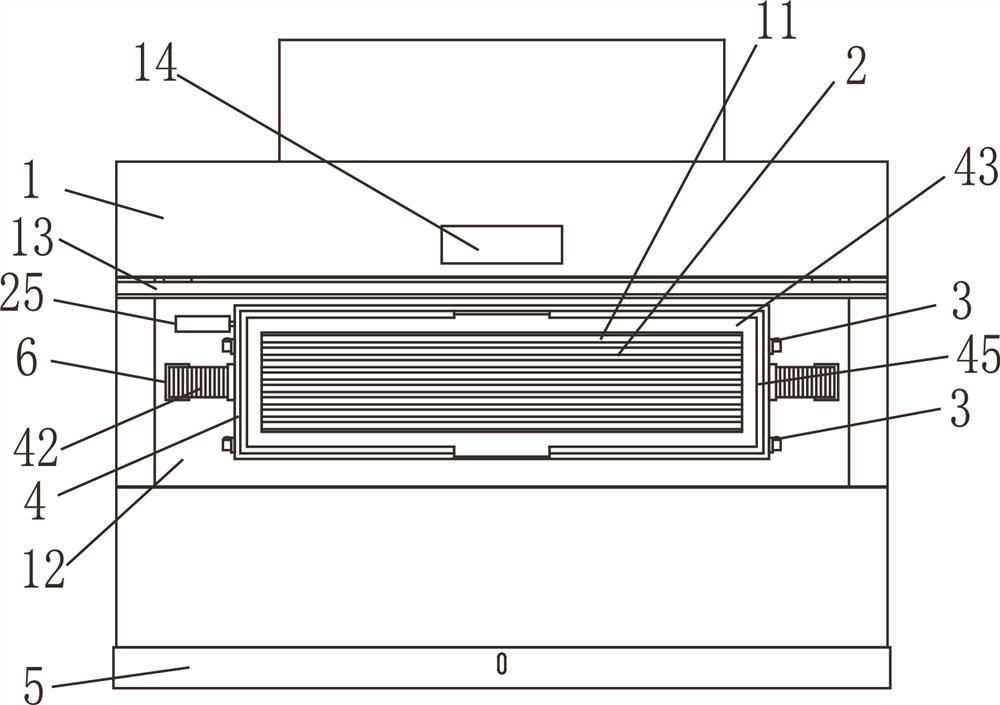

Oil filter device and range hood applying same

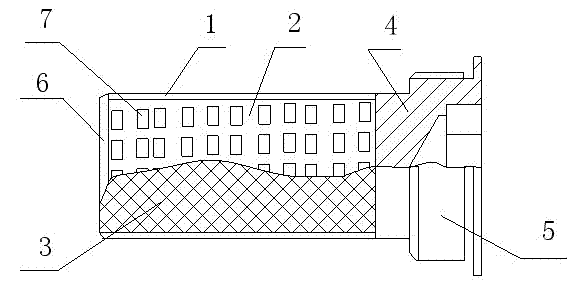

ActiveCN104296212AImprove oil filtration effectDomestic stoves or rangesLighting and heating apparatusThermodynamicsOil filter

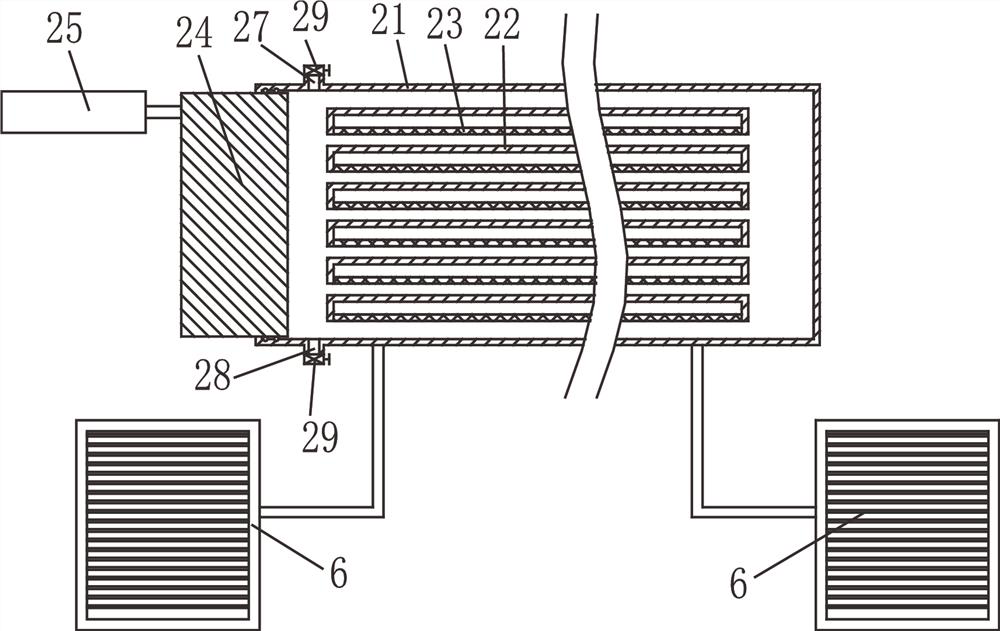

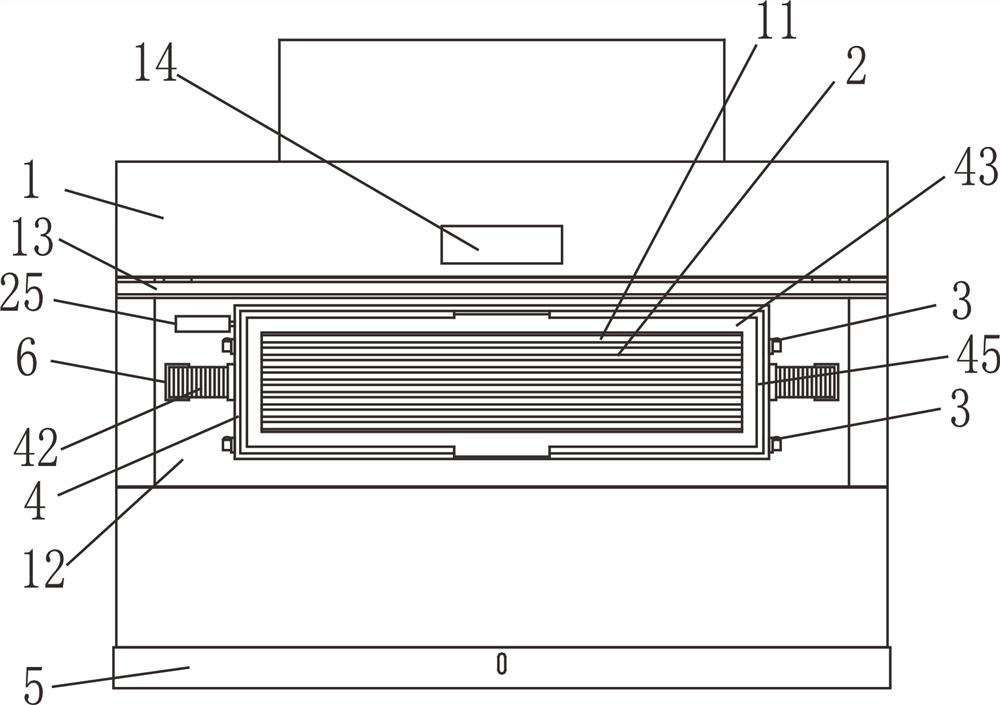

An oil filter device comprises a framework and an oil filter assembly arranged on the framework, and is characterized in that the framework is provided with a condensing liquid influx and a condensing liquid outflux; a first pipeline provided for a condensing liquid to flow through is formed inside the framework; the oil filter assembly is provided with a second pipeline provided for the condensing liquid to flow through and communicated with the first pipeline; and the first pipeline and the second pipeline together constitute a connecting channel between the condensing liquid influx and the condensing liquid outflux. The invention also discloses a range hood applying the oil filter device. The oil filter device and the range hood have the advantages that the condensing liquid produced from a condensing unit flows in through the condensing liquid influx, flows through the first pipeline and the second pipeline and then flows out from the condensing liquid outflux, the temperature of the oil filter assembly can be lowered to 0 DEG C or less, cooking fumes are rapidly condensed into oil droplets on the surface of the oil filter assembly when passing through the oil filter assembly, and thus the oil filtering effect is improved; and when the range hood adopting the oil filter device works, the cooking fume emissions are significantly reduced, and the cooking fume sucking effect is significantly improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

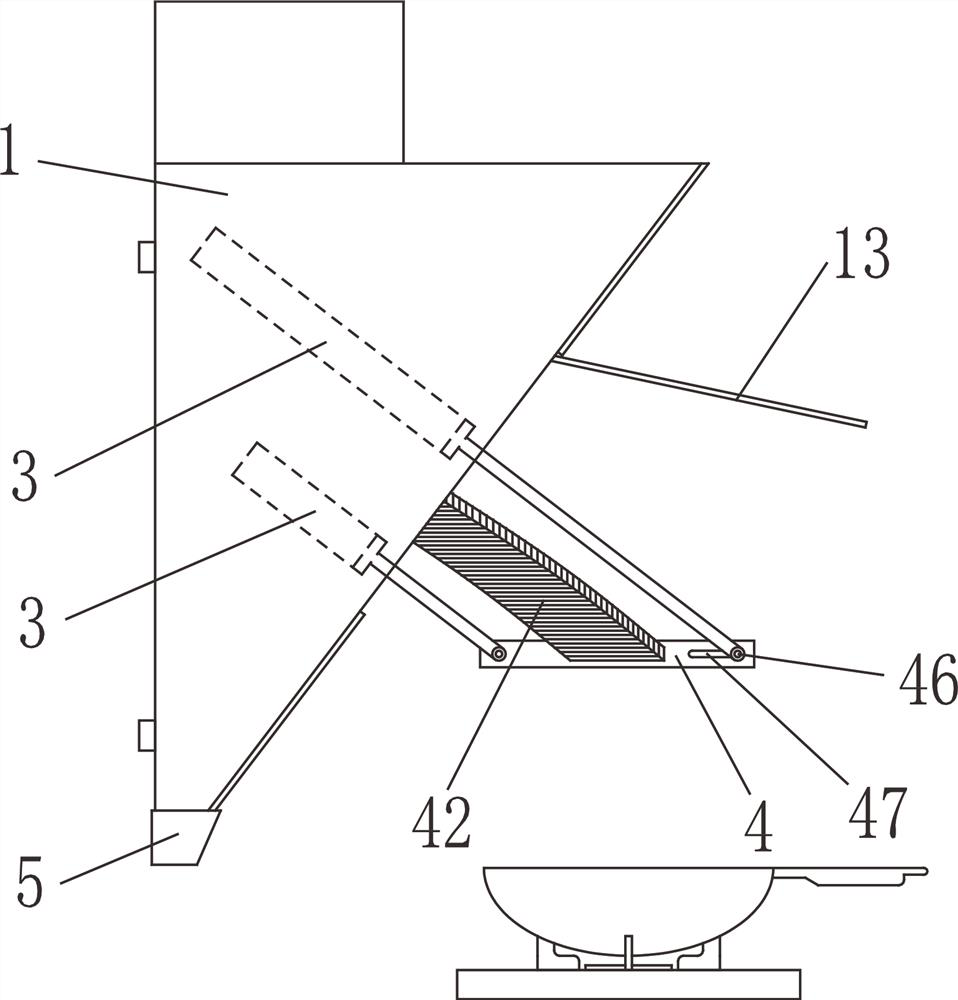

Oil filter type range hood

ActiveCN104266243AIncrease contact areaImprove oil filtration effectDomestic stoves or rangesLighting and heating apparatusExhaust fumesLiquid soap

The invention discloses an oil filter type range hood. The oil filter type range hood comprises a fan outer cover, an exhaust fume collecting hood, a filter screen and a rectifying plate arranged on the exhaust fume collecting hood and below the filter screen, wherein a fan is arranged in the fan outer cover, the range hood is characterized in that a bubble generator is arranged at an air inlet region between the rectifying plate and the filter screen, suction air current produced by the fan is matched with the bubble generator to product bubble blowing to the internal region between the rectifying plate and the filter screen. Compared with the prior art, the oil filter type range hood has the advantages that the bubble generator is arranged at an air inlet region between the rectifying plate and the filter screen, the fan can drive the airflow below the exhaust fume collecting hood to upward flow after bypassing the rectifying plate when being started, the airflow is blown to the bubble generator to enable the bubble generator to produce bubble, the contact area with the fume is increased by using the large surface area of the bubble, and the oil filter effect of the range hood is promoted by using the soluble performance of liquid soap to the grease under the condition of using the soap bubble.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

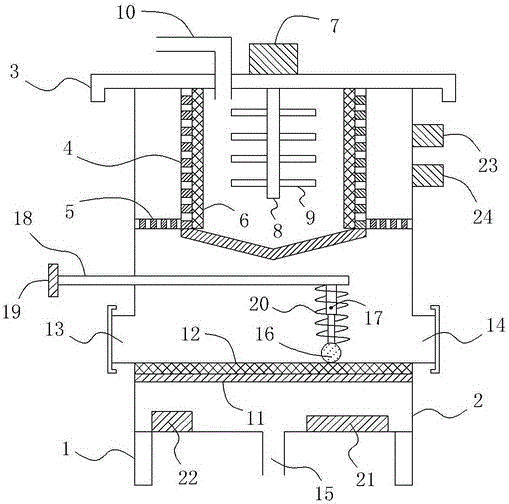

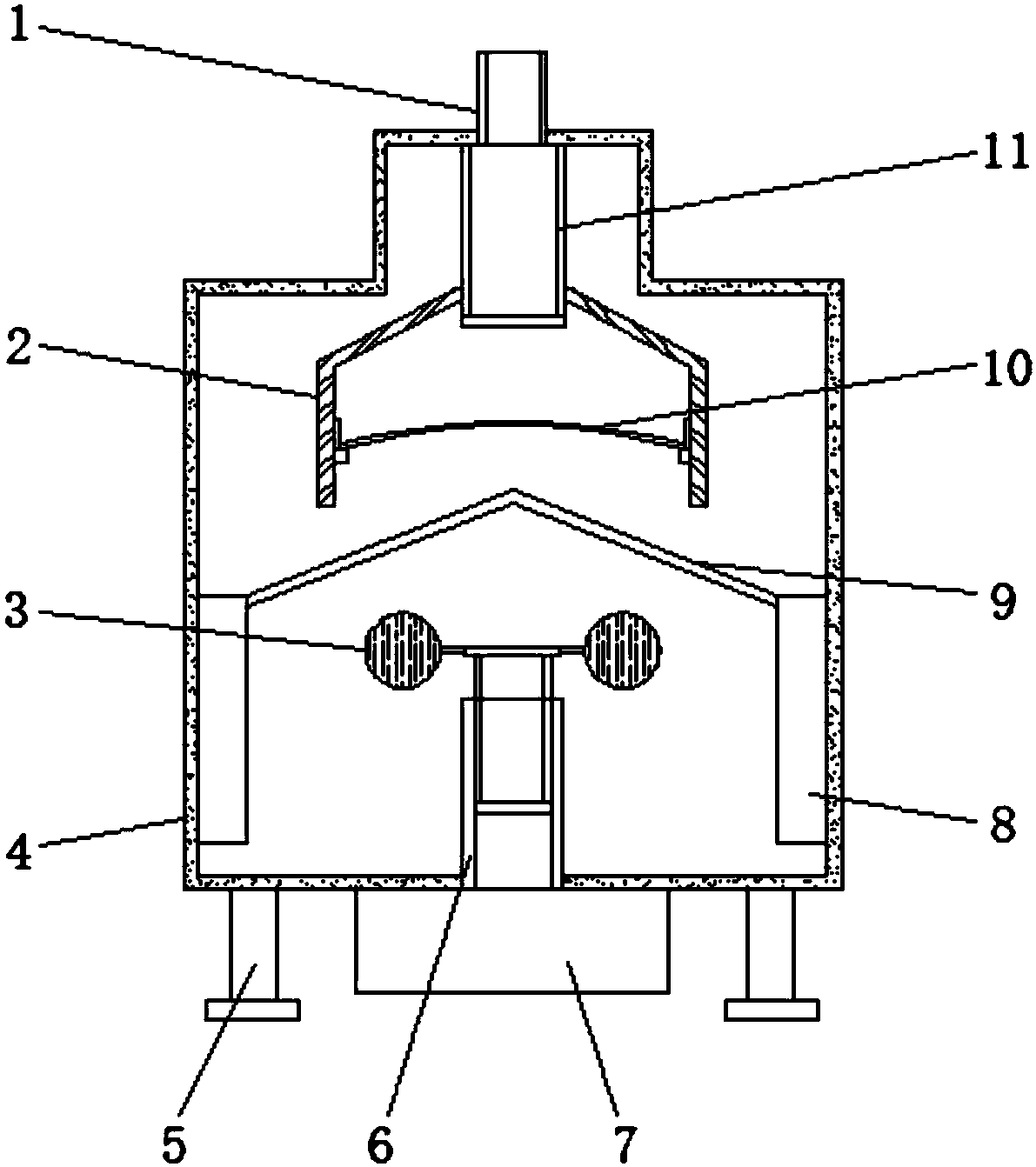

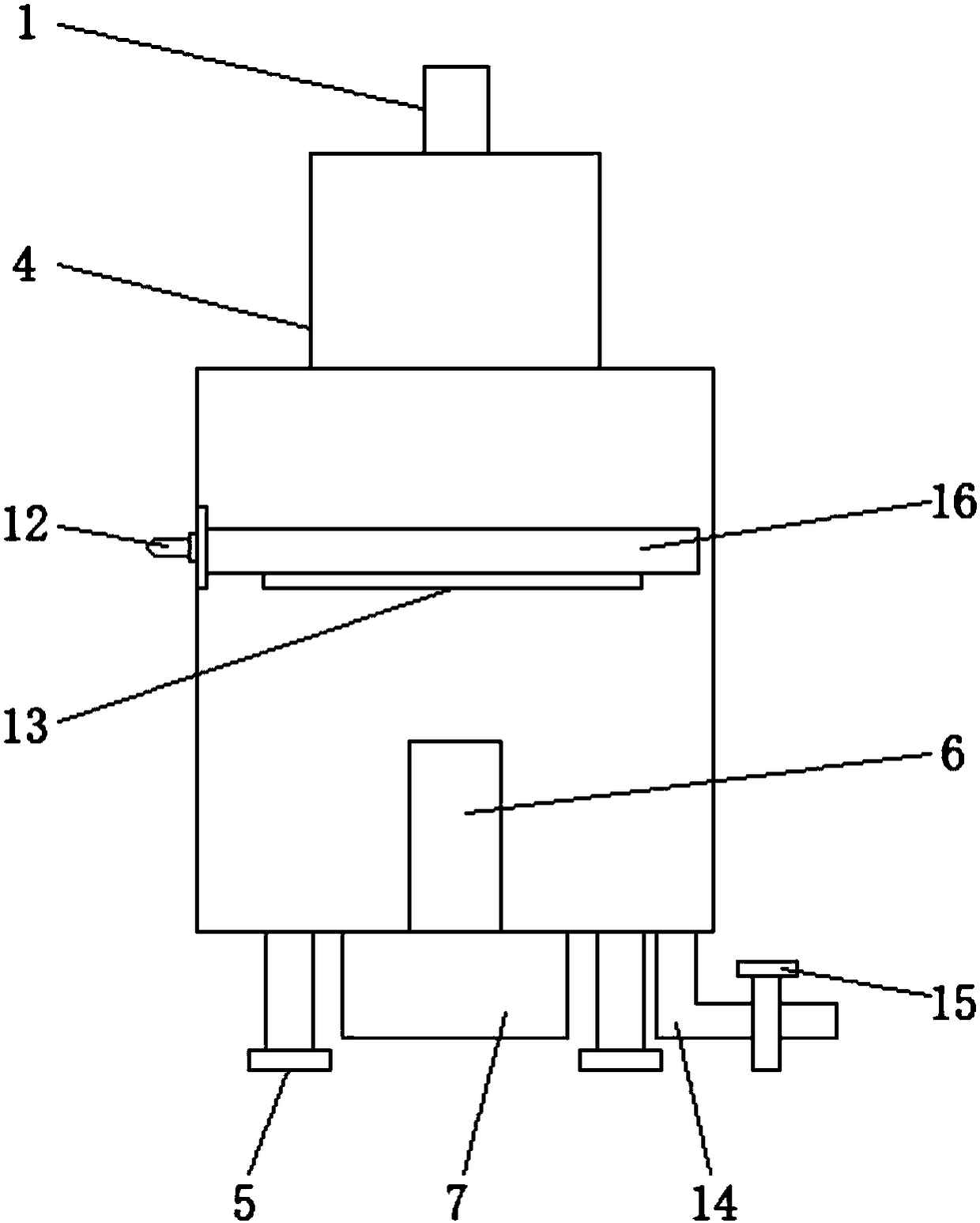

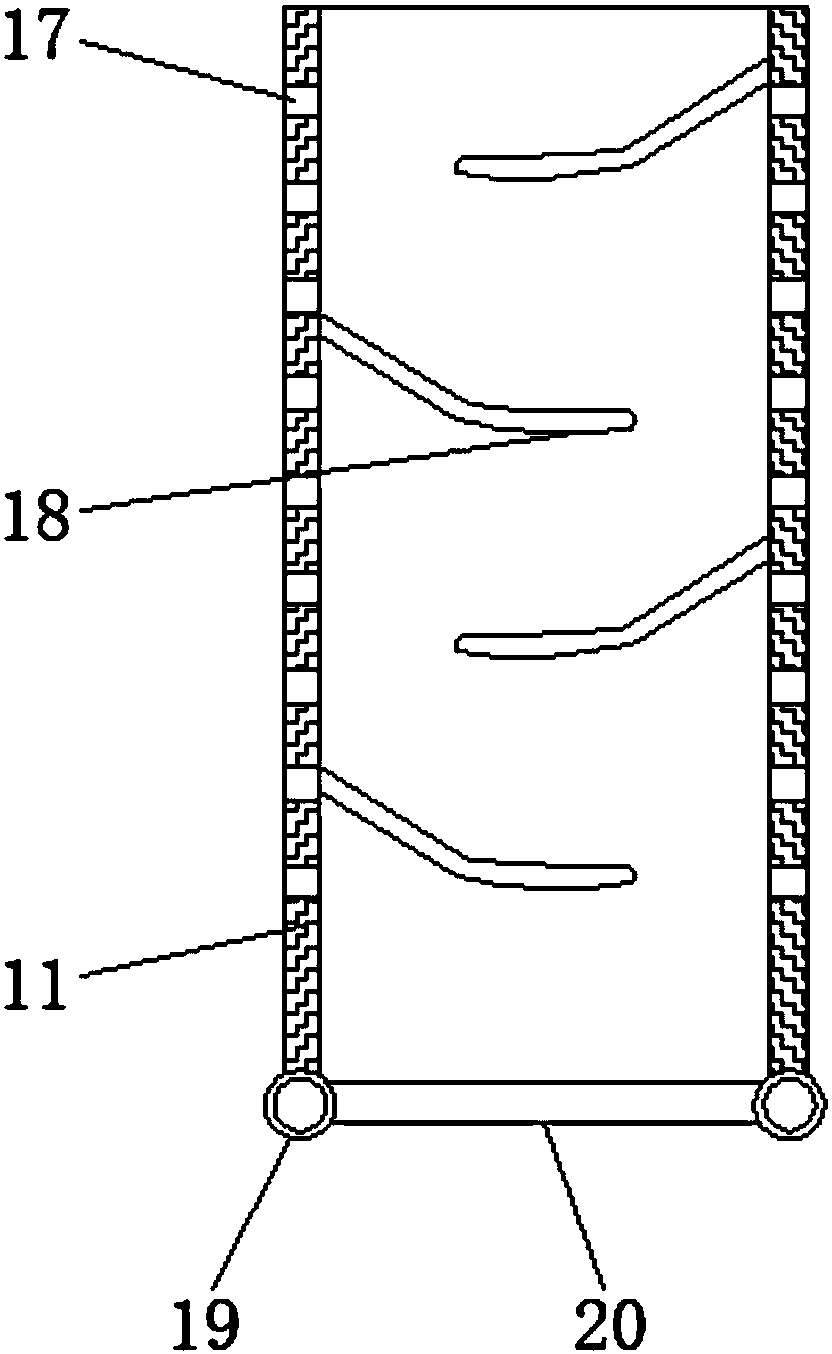

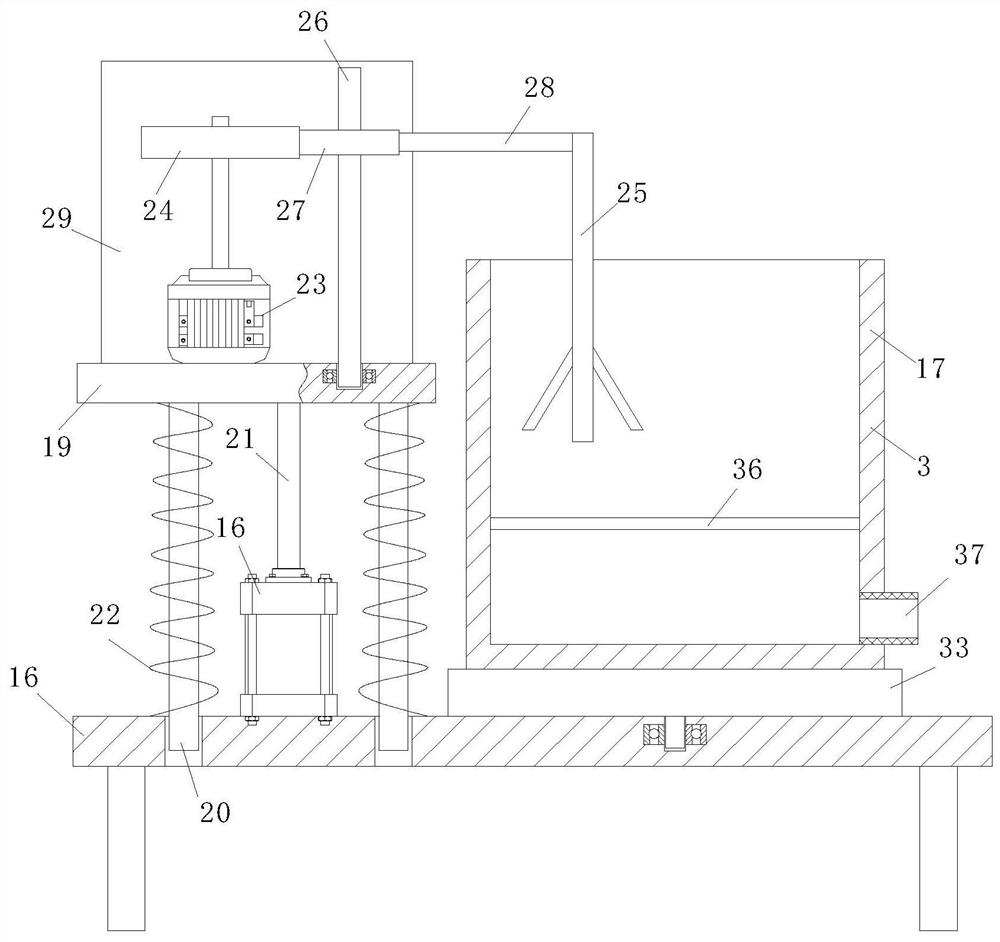

Novel electromechanical oil filtering device

InactiveCN106669245AEasy to cleanImprove efficiencyLoose filtering material filtersGravity filtersCoil springEngineering

The invention relates to a novel electromechanical oil filtering device. The novel electromechanical oil filtering device comprises a bracket, a box body and a box cover, wherein a filter cartridge is arranged in the box body; an annular filtering plate sleeves the bottom end of the filter cartridge; filtering holes are formed in a vertical side wall of the filter cartridge and the annular filtering plate; a first filter screen covers the inner surface of the filter cartridge; a motor is arranged on the box cover, and the motor is connected with a rotary shaft; stirring rods are distributed on the rotary shaft; an oil inlet pipe is arranged on the box cover; a separation plate is arranged below the filter cartridge; a separation plate through hole is formed in the separation plate; a second filter screen further covers the separation plate; a left cleaning hole and a right cleaning hole are respectively formed in left and right sides of the box body located above the separation plate; a bottom wall of the box body is connected with an oil outlet pipe; the second filter screen is provided with a brush rod; the top end of the brush rod is connected with a retractable rod; a pull rod is connected with the top end of the retractable rod; a handle is arranged at the left end of the pull rod; a spiral spring sleeves the retractable rod. With the adoption of the structure, the oil filtering efficiency and the oil filtering effect can be remarkably enhanced, so that the utilization performance is greatly improved.

Owner:CHENGDU JUZHI IND DESIGN

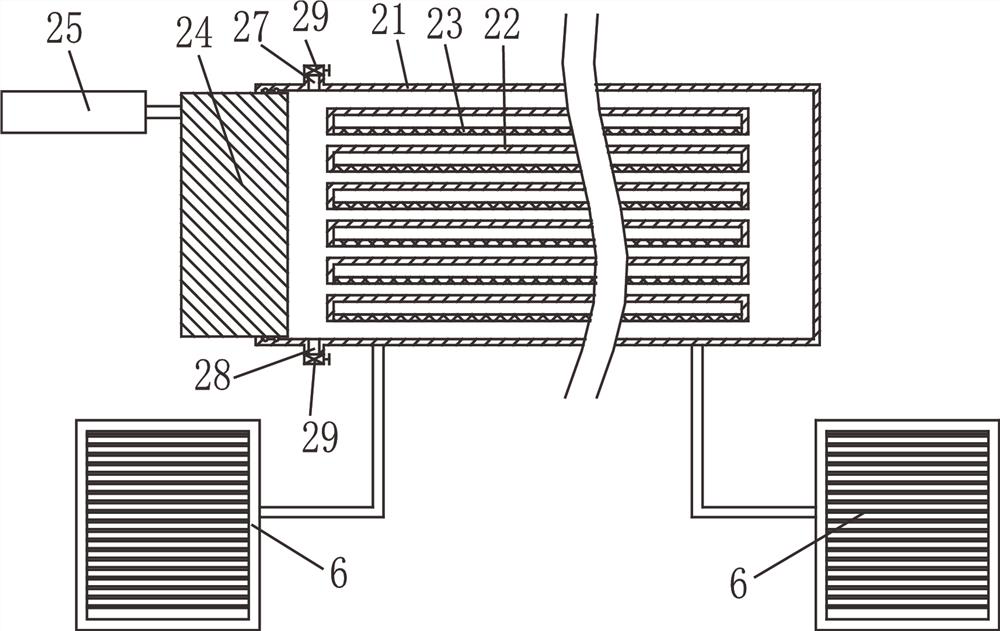

Novel oil filtering dryer assembly

InactiveCN107854975AExtended service lifeHigh strengthGas treatmentDispersed particle filtrationMolecular sieveImpurity

The invention discloses a novel oil filtering dryer assembly which comprises a pressure spring, a shell, an inner cylinder cover, an inner cylinder, a molecular sieve, a flange plate, an end cover, asealing ring and an O-shaped ring. The inner cylinder cover is installed at an opening in the top of the inner cylinder, the inner cylinder and the inner cylinder cover are both arranged inside the shell, the pressure spring is arranged between the inner cylinder cover and the top of the shell, the bottom of the inner cylinder is placed on the flange plate, and a center hole and an eccentric holeare formed in the center and the eccentric position of the flange plate respectively. The novel oil filtering dryer assembly has the advantages that due to the structure, a vacuum sponge gasket insidean existing drying cylinder is replaced with a stainless steel wire filter net, the good ventilation performance can be ensured while the strength of the filter net is improved, a molecular sieve isprotected, oil contamination on the filter net can be effectively brought away, the oil filtering effect is effectively enhanced, and the service life of the drying cylinder is prolonged; the qualityof the filter net is improved, and the phenomenon that impurities are generated due to the fact that the filter net is damaged earlier and blown out is avoided.

Owner:十堰莱安汽车零部件有限公司

Novel oil filter

InactiveCN103089607APromote repairLow costPositive displacement pump componentsLiquid fuel engine componentsBiochemical engineeringOil filter

The invention discloses a novel oil filter comprising a casing and a filter core arranged in the casing. The filter core comprises a framework and a filter screen sleeved on the framework. The novel oil filter is characterized in that one end of the filter screen is connected with a threaded joint, and the other end of the filter screen is connected with a U-shaped sheet joint. The novel oil filter has the advantages of simple structure, convenience in maintenance and easiness in cleaning.

Owner:NANTONG XINFENGXIANG HYDRAULIC CASTING

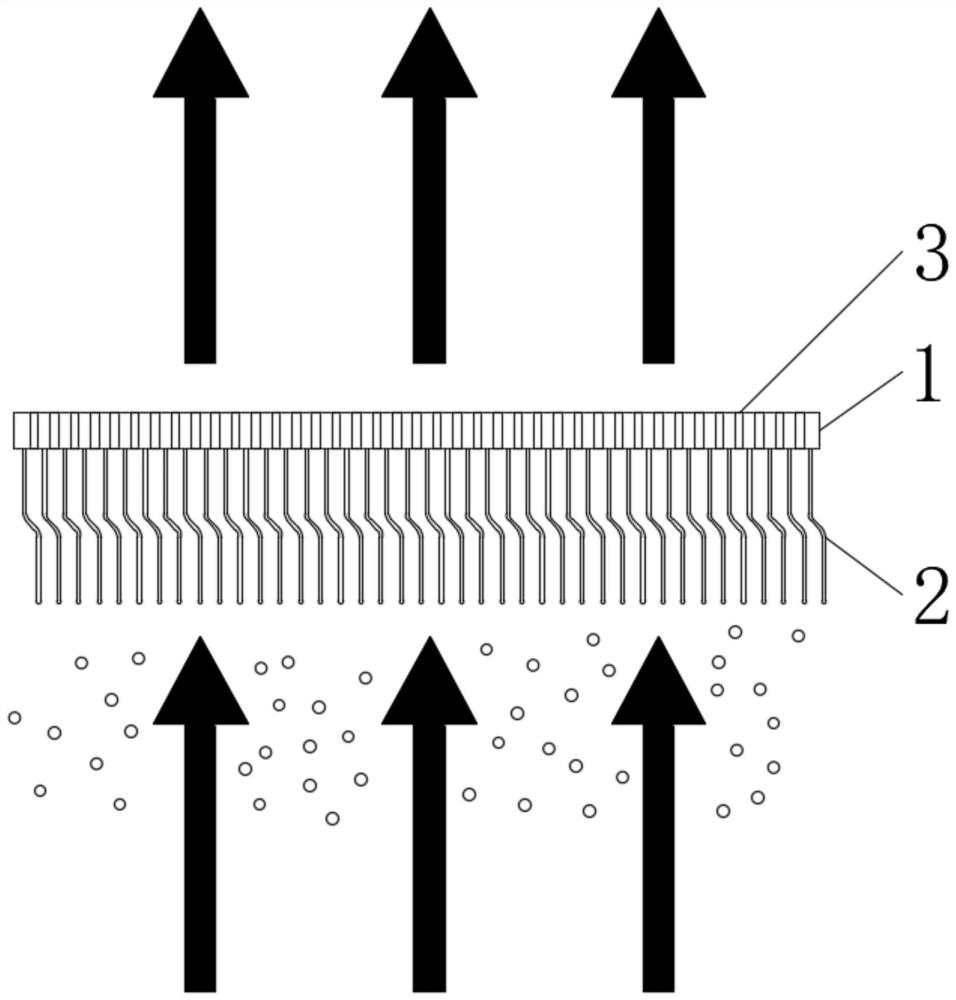

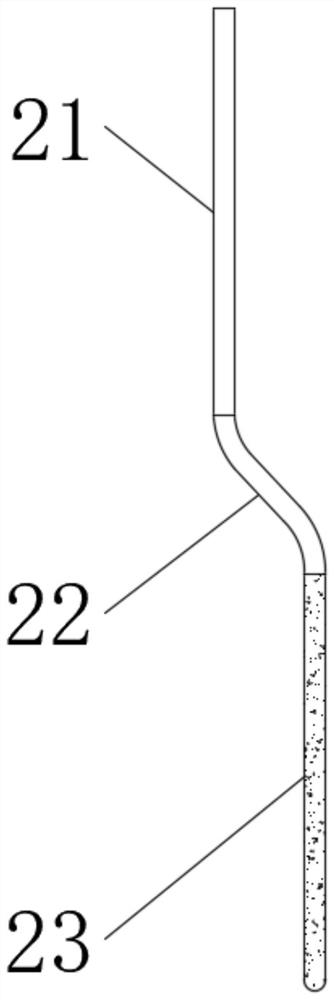

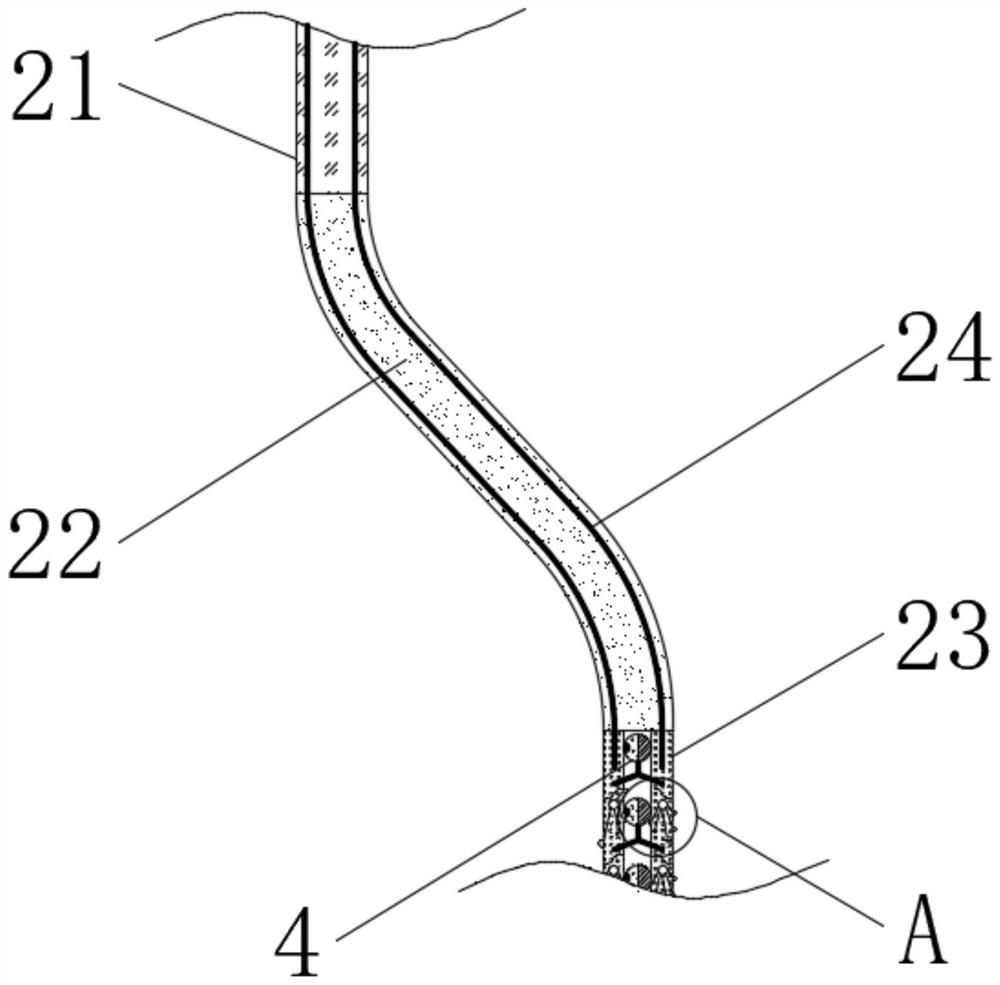

Self-deflection oil filtering device for oil-containing waste gas treatment

InactiveCN111888850AExtended service lifeLarge oil absorptionDispersed particle filtrationExhaust fumesFiber

The invention discloses a self-deflection oil filtering device for oil-containing waste gas treatment. The invention belongs to the technical field of oily waste gas treatment. Densely distributed segmental oil filtering fiber rods can be arranged at the lower end of an oil filtering plate; the characteristic that the upper and lower parts have deflection distances is utilized; an oil absorption gap between the adjacent segmental oil filtering fiber rods is eliminated; the contact sufficiency is improved in a space range; therefore, the oil filtering effect and efficiency of the oil-containingwaste gas are improved; after the segmental oil filtering fiber rods adsorb, saturate and gain weight; a lower movable oil filtering fiber rod on the segmental oil filtering fiber rods forces a middle deflection transition rod to generate self-deflection action due to the reason that the weight is increased; a pre-embedded magnetic pressure liquid release ball is used for carrying out extrusion action based on the magnetic repulsion effect, so that an emulsifier for oil stains is released and is guided to the emulsification-promoting disintegration microsphere, and the permeation of the emulsifier and the emulsification of the oil stains are accelerated by utilizing the characteristic that the emulsification-promoting disintegration microsphere fiercely releases gas and vibrates when meeting water.

Owner:刘宝军

Method for preparing air filter material

InactiveCN109954319AGood oil filter effectImprove mechanical propertiesMembrane filtersFiltration separationAir filtrationAbsorption capacity

The invention discloses a method for preparing an air filter material. The method comprises the following steps: preparation of a filter substrate, preparation of a filter film, and preparation of theair filter material. Polytetrafluoroethylene added to the air filter material enhances the tensile strength and the acid and alkali resistance of the filter film, so it is ensured that the filter film has a good oil filter performance and good mechanical properties and can adapt to air filtration in different environments including oil, acid or alkaline gases; the addition of polypropylene fibersand silica improves the oil filtration performance; the filter substrate and the filter film are quickly integrated by a filter material integration device to improve the production efficiency, so the adhesion of the filter substrate and the filter film is ensured; and activated carbon is compacted by a pressing plate to make the activated carbon sufficiently adhered to the surface of the air filter material, so the absorption capacity of the air filter material against toxic gases and other gases harmful to the human body is enhanced.

Owner:瑞德纳米科技(广州)有限公司

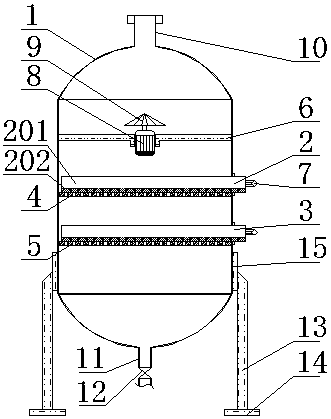

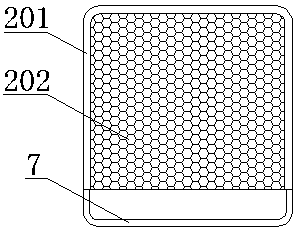

Oil residue filtering device for production of chemical raw materials

InactiveCN107774028APrevent the effect of oil filtrationImprove oil filtration effectMembrane filtersStationary filtering element filtersFixed frameFlow divider

The invention relates to an oil residue filtering device for production of chemical raw materials. The oil residue filtering device comprises an equipment shell body, an upper filtering plate and a lower filtering plate, wherein an upper supporting plate is arranged below the upper filtering plate; a lower supporting plate is arranged on the lower surface of the lower filtering plate; pull rods are arranged on the upper filtering plate and the lower filtering plate; a motor is mounted and fixed above the upper filtering plate through a fixing frame; a conical flow divider is mounted above themotor; a material inlet is formed in the top of the equipment shell body and a material outlet is formed in the bottom end of the equipment shell body; a stop valve is mounted below the material outlet; supporting legs are further arranged at the lower end of the equipment shell body; a bottom plate is fixed at the lower ends of the supporting legs; base plates are arranged at connecting parts ofthe supporting legs and the equipment shell body. According to the oil residue filtering device provided by the invention, two layers of the filtering plates which can be movably taken out are additionally arranged in the shell body and can be used for filtering oil residues layer by layer, so that the oil filtering effect is increased; the conical flow divider is arranged in the shell body so that raw materials are dispersed in an oil filtering process, so that a condition that filtering residues are accumulated to cause blocking so that an oil filtering effect is influenced is prevented; theoil residue filtering device provided by the invention has a relatively simple structure and relatively high practicability and is suitable for popularization and application.

Owner:JIANGSU JIHUA CHEMICAL CO LTD

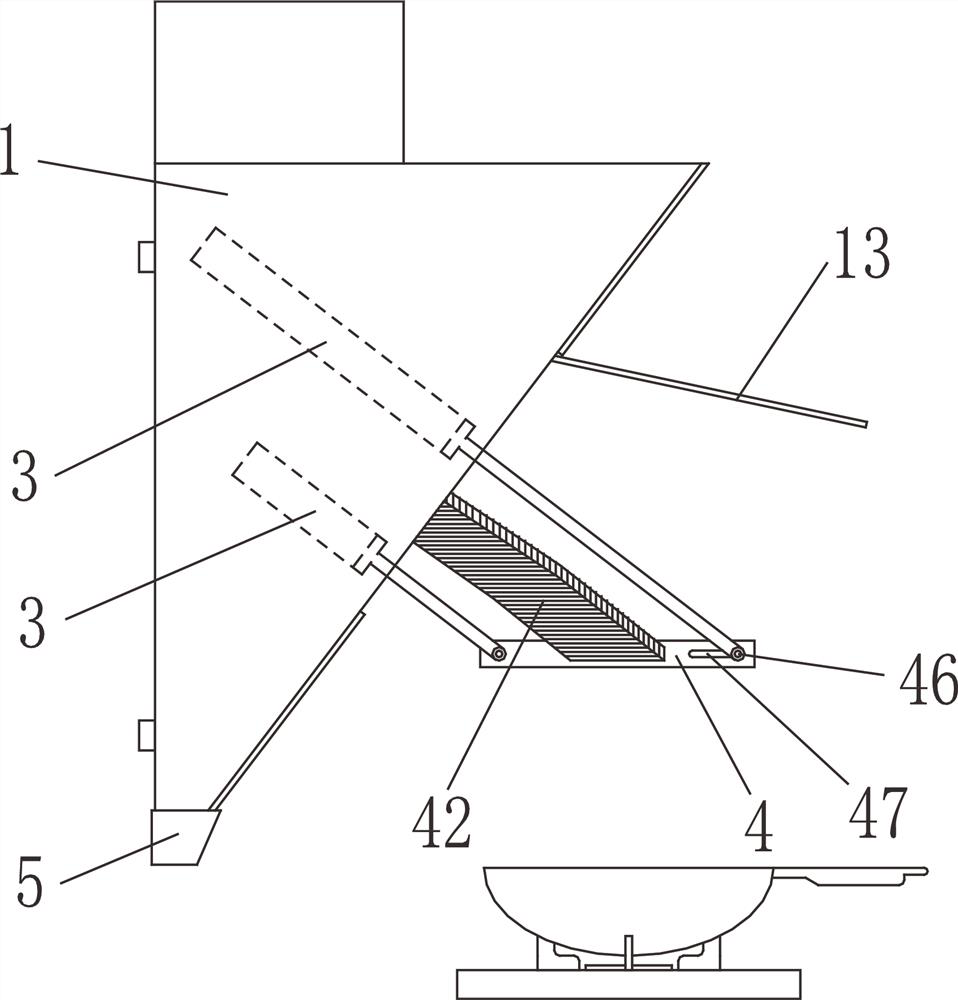

Environment-friendly collection and treatment device of kitchen swill

InactiveCN108553997AFacilitate unified collection and managementEasy to cleanFiltration circuitsFuel tankOil filter

The invention discloses an environment-friendly collection and treatment device of kitchen swill. The environment-friendly collection and treatment device comprises a housing, an oil storage tank, a partition and a filter pipe, wherein a swill inlet pipe is fixedly arranged on the upper surface of the housing; the filter pipe is fixed at the upper end in the housing; the swill inlet pipe is communicated with the filter pipe; arc plates are fixed in the filter pipe; the two ends of the bottom of the filter pipe are rotationally connected with two baffles through torsional springs respectively;a side baffle is welded to one end, close to the bottom, of the filter pipe; fixing blocks are fixed at the two ends in the side baffle; a filter drawer cage is fixed at the tops of the two fixing blocks; a convex filter screen is fixed in the filter drawer cage; a handle is fixed at one end of the filter drawer cage; the partition is mounted below the side baffle; connecting pipes are welded at the two ends of the partition; an oil filter outer pipe is welded to the lower surface in the housing. The device has the advantages that the device can centrally collect solid waste, does not need tobe cleaned frequently and saves time and labor.

Owner:FOSHAN JINJINGCHUANG ENVIRONMENTAL PROTECTION TECH CO LTD

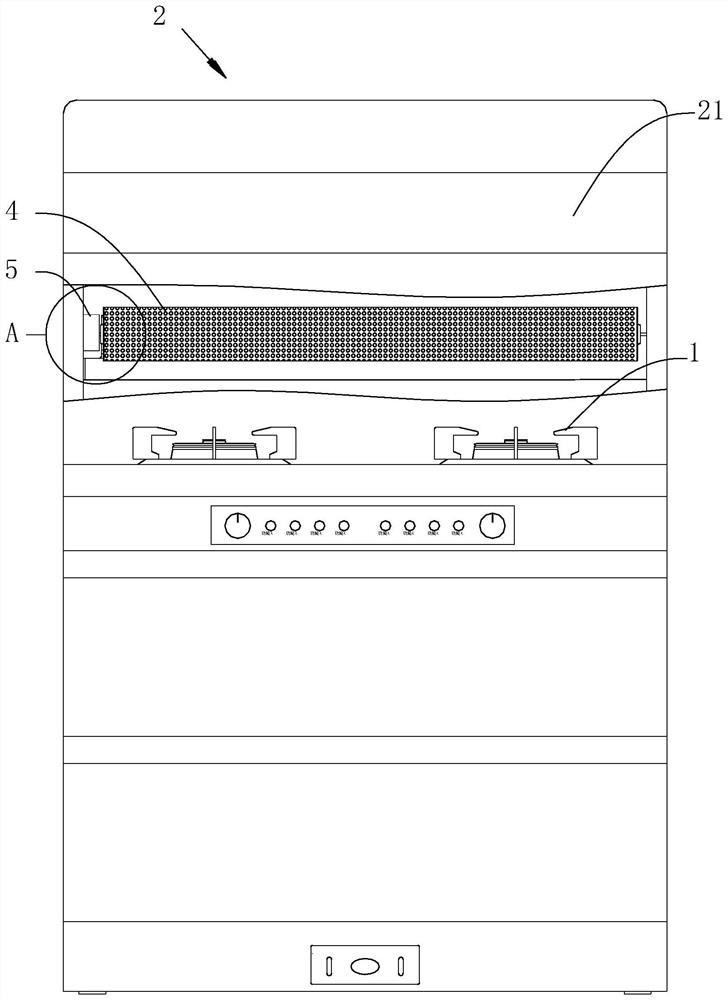

Range hood

ActiveCN112161310ALow powerImprove efficiencyDomestic stoves or rangesLighting and heating apparatusStructural engineeringRubber sheet

The invention discloses a range hood. The range hood comprises an range hood body, a draught fan and a control circuit board are arranged in the range hood body, an oil fume suction port is formed inthe range hood body, an oil filtering barrier is arranged on the oil fume suction port and comprises a frame and parallel oil filtering barrier plates arranged in the frame, the frame is in communication with the oil filtering barrier plates in a hollow mode, cooling water is arranged in the frame and the oil filtering barrier plates, at least one side of the oil filtering barrier plate is provided with an opening, an elastic rubber sheet is arranged on the opening, movable plugs are arranged on the two opposite sides of the frame, a tension spring is arranged between the movable plugs, firstinclined faces are arranged on the side faces of the movable plugs, electric push rods are arranged on the machine body, the telescopic ends of the electric push rods are connected with a hollow oil fume suction ring, oil fume suction holes are formed in the inner side ring face of the oil fume suction ring, and oil fume suction pipelines are arranged between the oil fume suction ring and the machine body. According to the range hood, the oil fume suction ring can be lifted as required, an original oil fume suction port can be automatically opened and closed in the lifting process, and the oilfiltering effect of the oil filtering barrier is better.

Owner:绍兴依利奥厨具有限公司

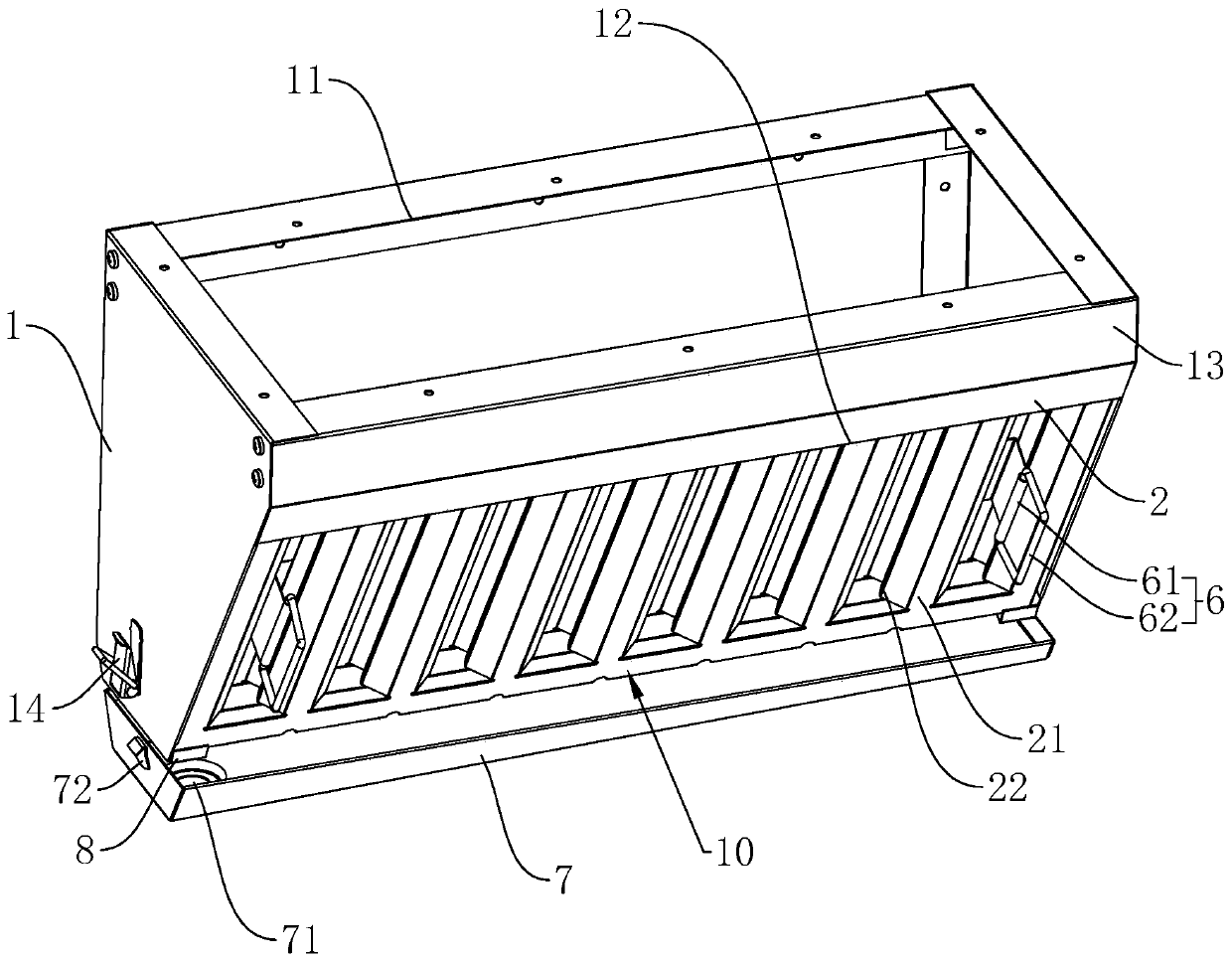

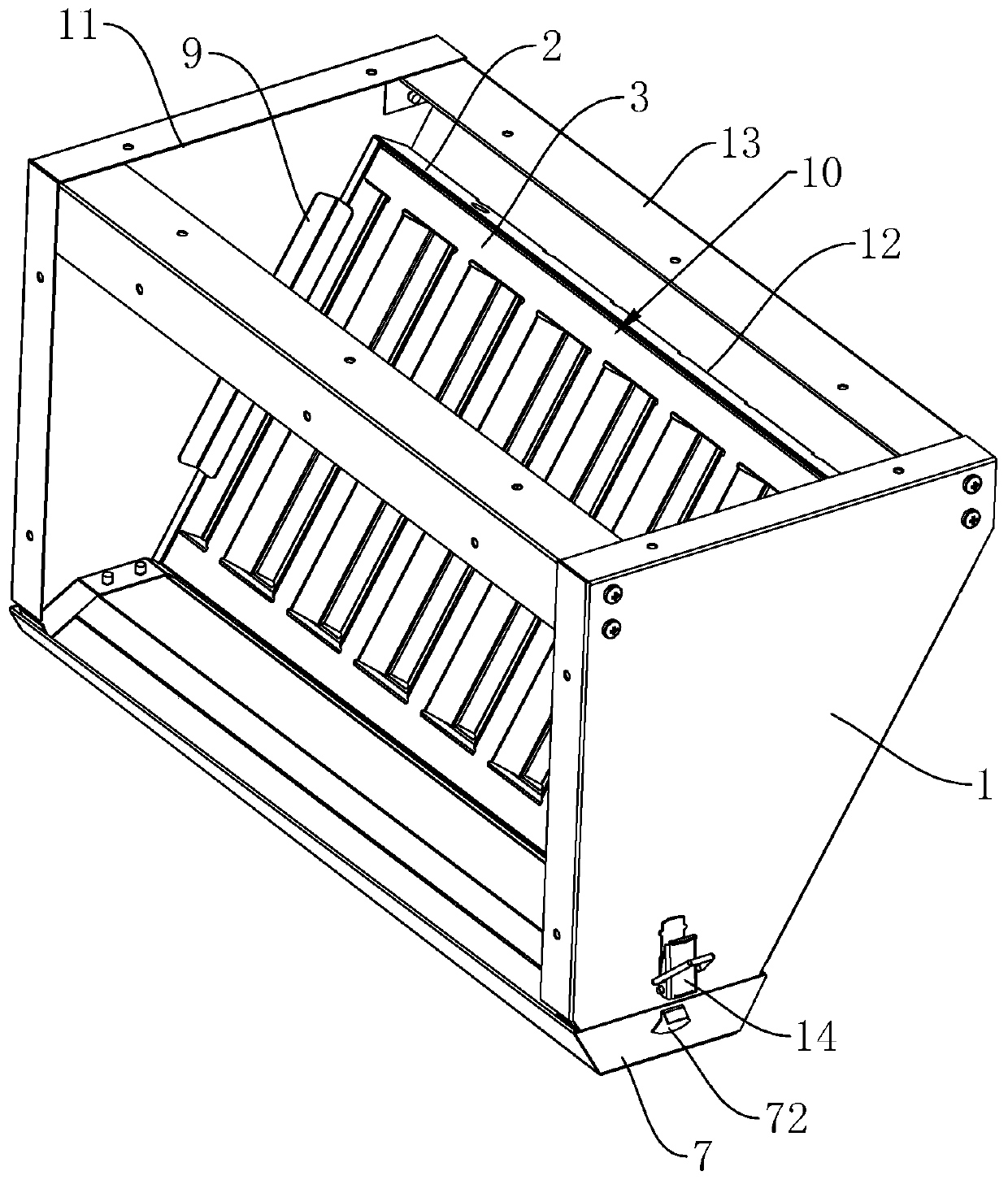

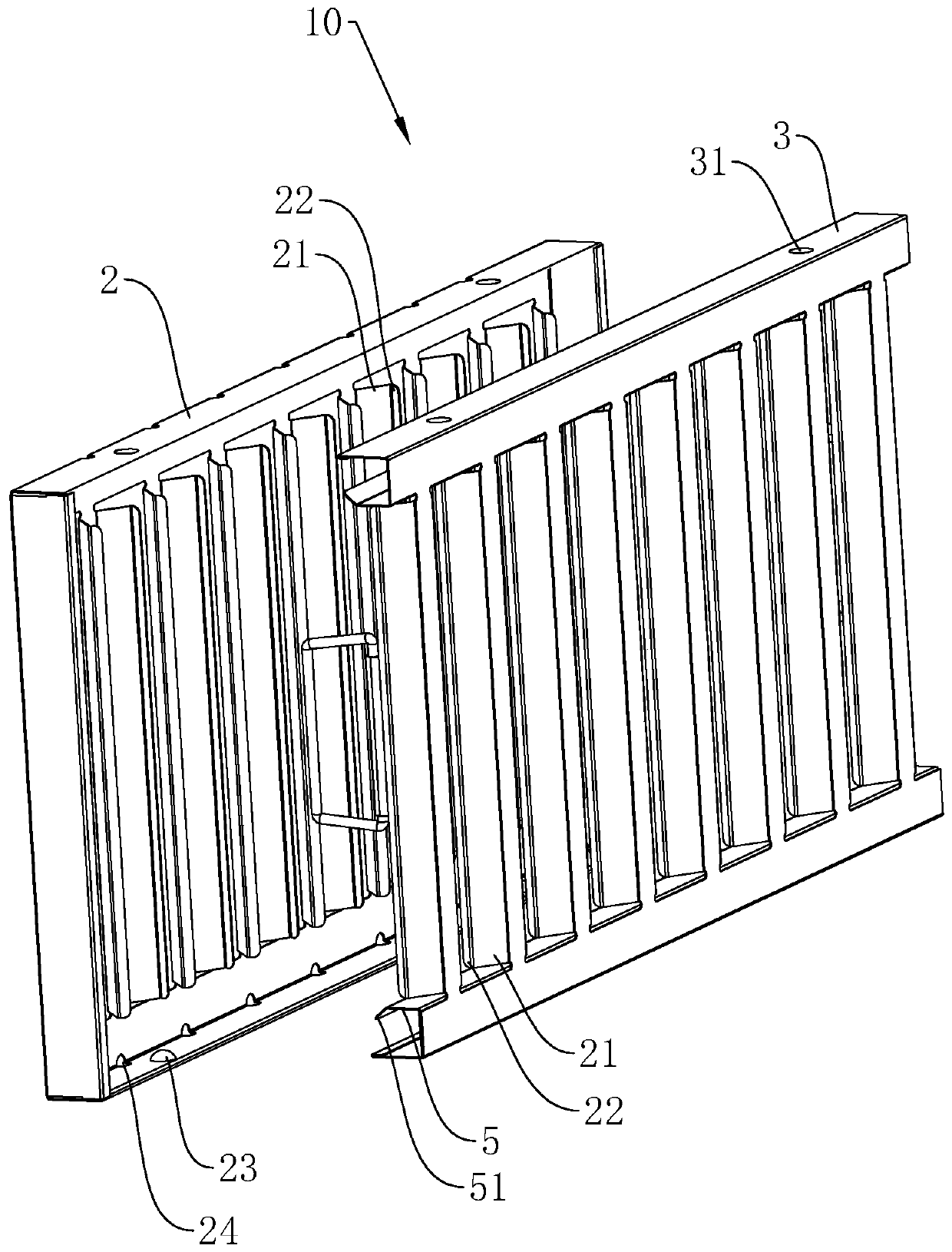

Lampblack filter with primary filter function

ActiveCN109373385AExtend the motion pathIncrease contact areaDomestic stoves or rangesLighting and heating apparatusEngineeringOil filter

The invention discloses a lampblack filter with a primary filter function, and belongs to the field of lampblack purifying devices. The lampblack filter comprises an air box; an air sucking port and an intake port are arranged on the top wall and the side wall of the air box; a first oil filter frame and a second oil filter frame, buckled with each other, are arranged in the intake port; multiplefirst guide plates bent into the air box are arranged on opposite side walls of the first oil filter frame and the second oil filter frame in parallel; two ends of the first guide plates are connectedwith second guide plates inwards bent; and the first guide plates and the second guide plates on the first oil filter frame are staggered from the first guide plates and the second guide plates on the second oil filter frame to form zigzag lampblack channels. The lampblack filter achieves the following effects: as oil drops in lampblack can be stopped, the oil drops are not easy to directly enterthe filter.

Owner:SUZHOU ZHAOHE ENVIRONMENT & ENERGY TECH CO LTD

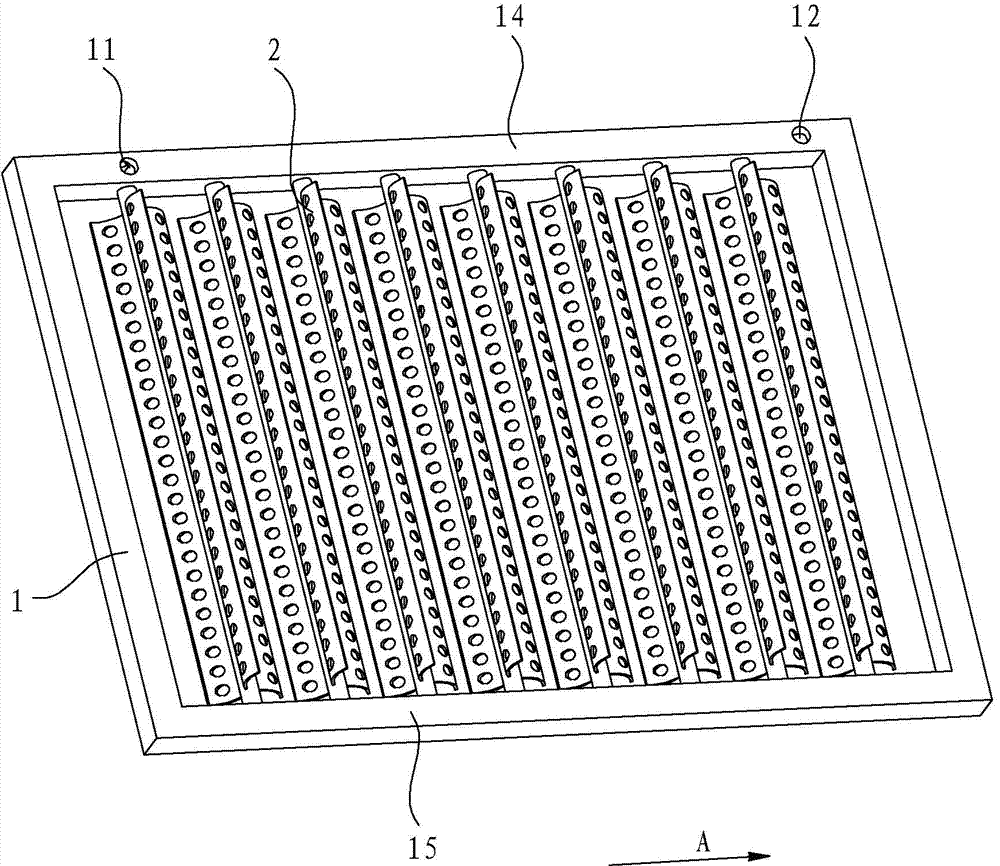

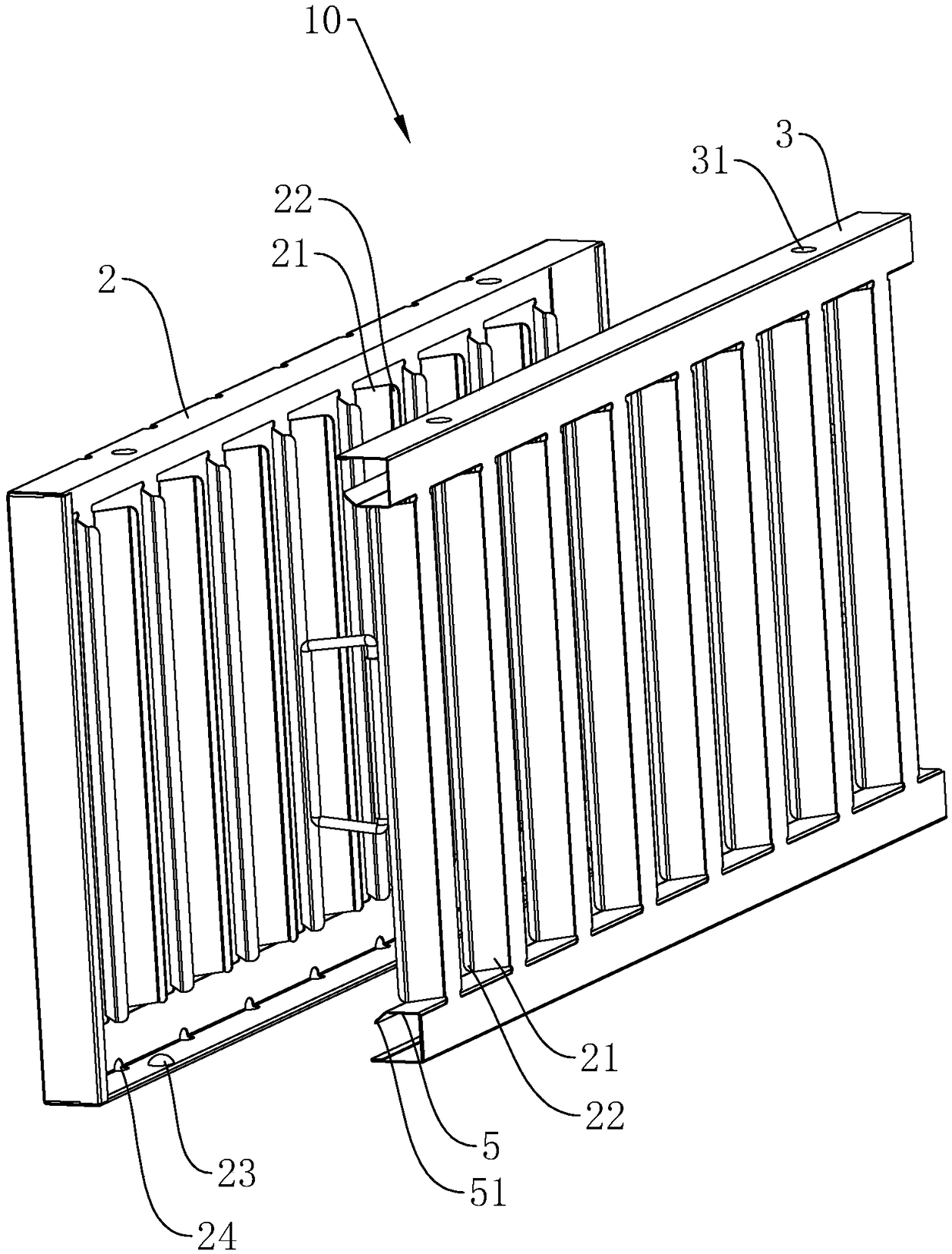

Multistage filtering device used for extractor hood

PendingCN107965810AImprove oil filtration effectDomestic stoves or rangesLighting and heating apparatusPetroleum engineering

A multi-stage filter device for a range hood, characterized in that it includes an oil filter plate, the oil filter plate has a U-shaped oil filter groove formed by indenting toward the same side of the oil filter plate, and the U-shaped filter plate The oil grooves are parallel to each other and distributed at intervals in turn. On the two opposite side walls of the U-shaped oil filter groove, there are respectively a first oil filter hole and a second oil filter hole. The first oil filter hole and the second oil filter hole are both Distributed at intervals along the length direction of the U-shaped oil filter groove and staggered from each other. The present invention has the advantages that: because the U-shaped oil filter grooves of the oil filter plate of the multi-stage filter device are parallel to each other and distributed in intervals in sequence, and the first oil filter hole and the second oil filter hole on the two opposite side walls of the U-shaped oil filter groove They are distributed at intervals along the length direction of the U-shaped oil filter groove and staggered from each other. Therefore, the oil fume entering the U-shaped oil filter groove can pass through the first oil filter hole and the inner surface of the oil filter groove while colliding with the inner surface of the oil filter groove. The side walls collide, thereby further improving the oil filtering effect.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

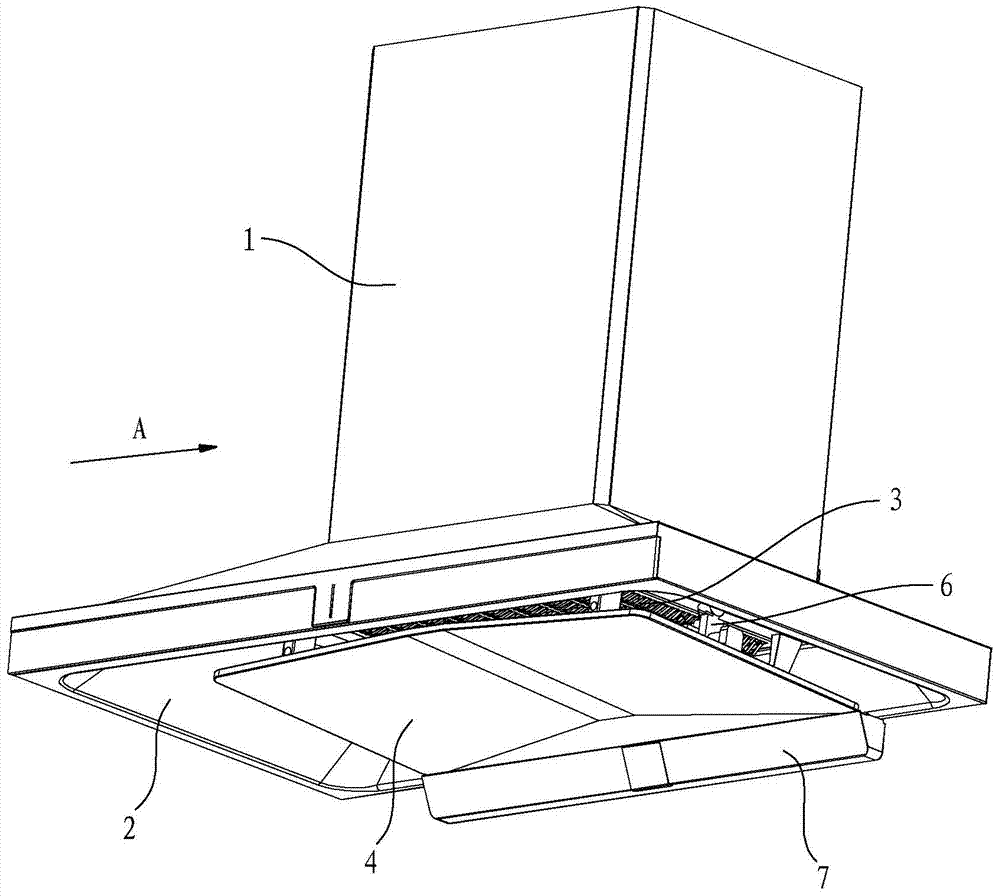

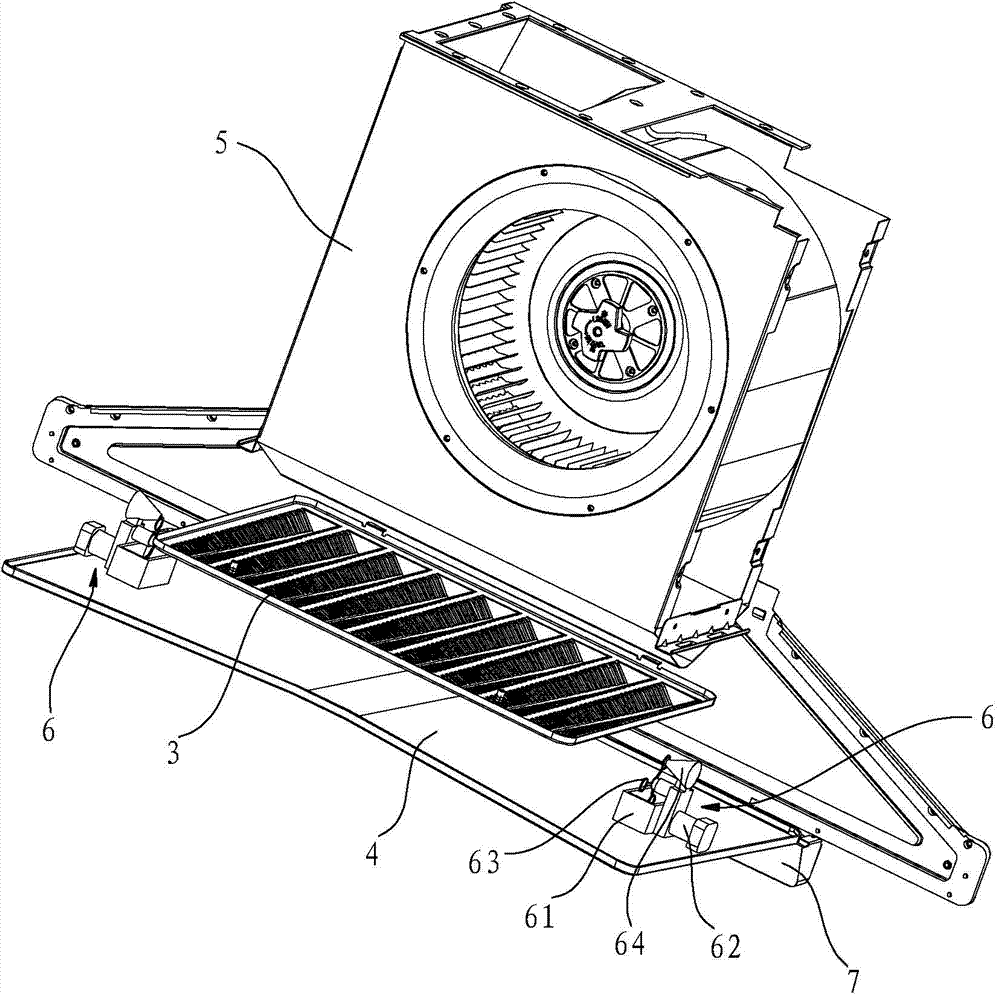

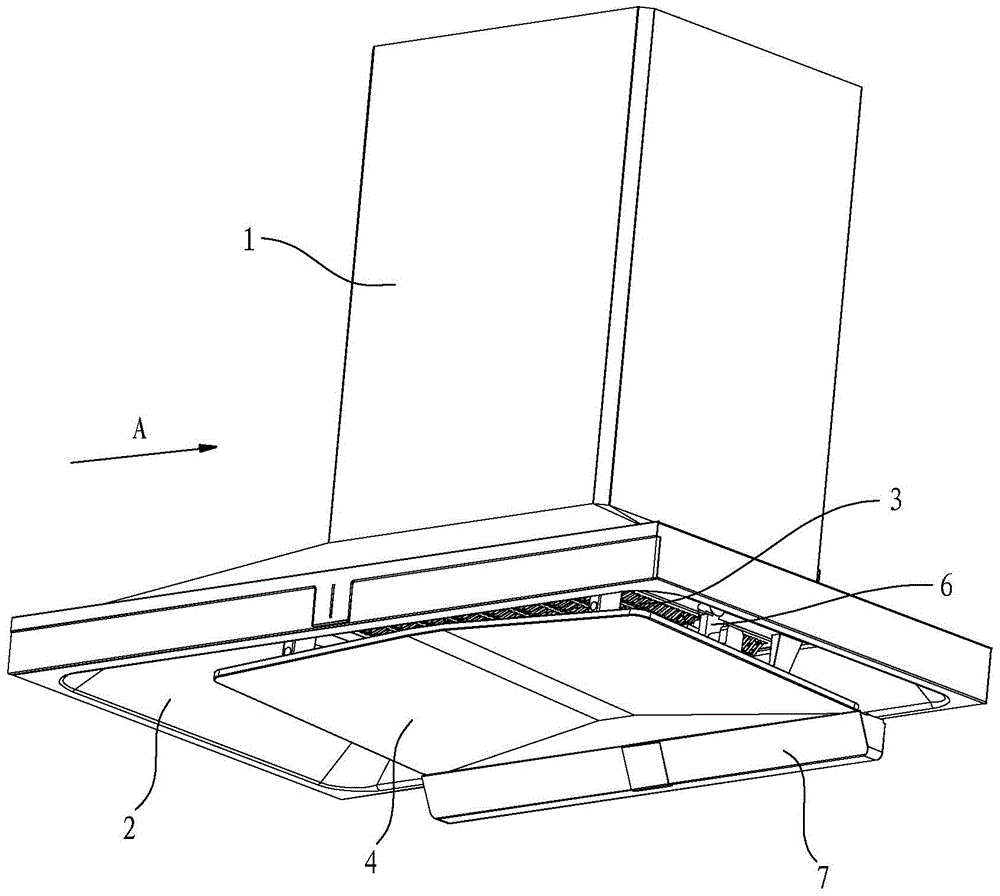

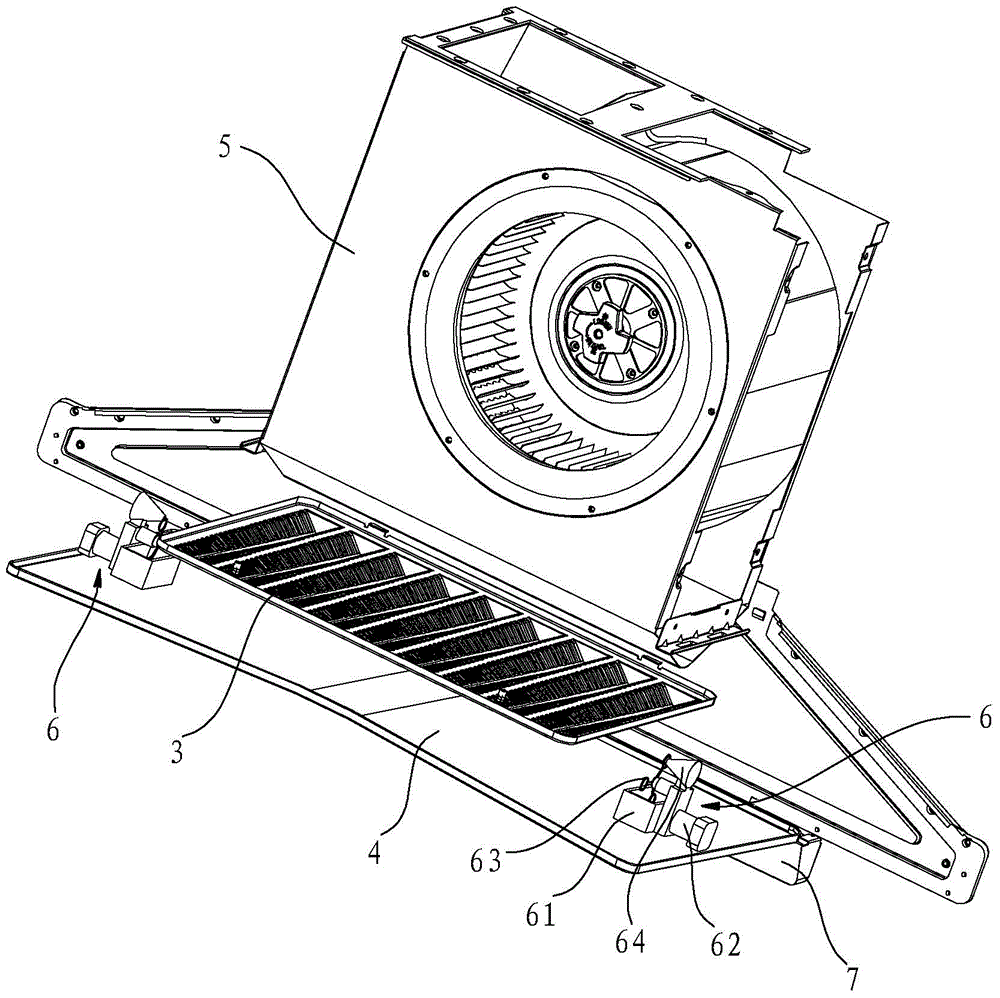

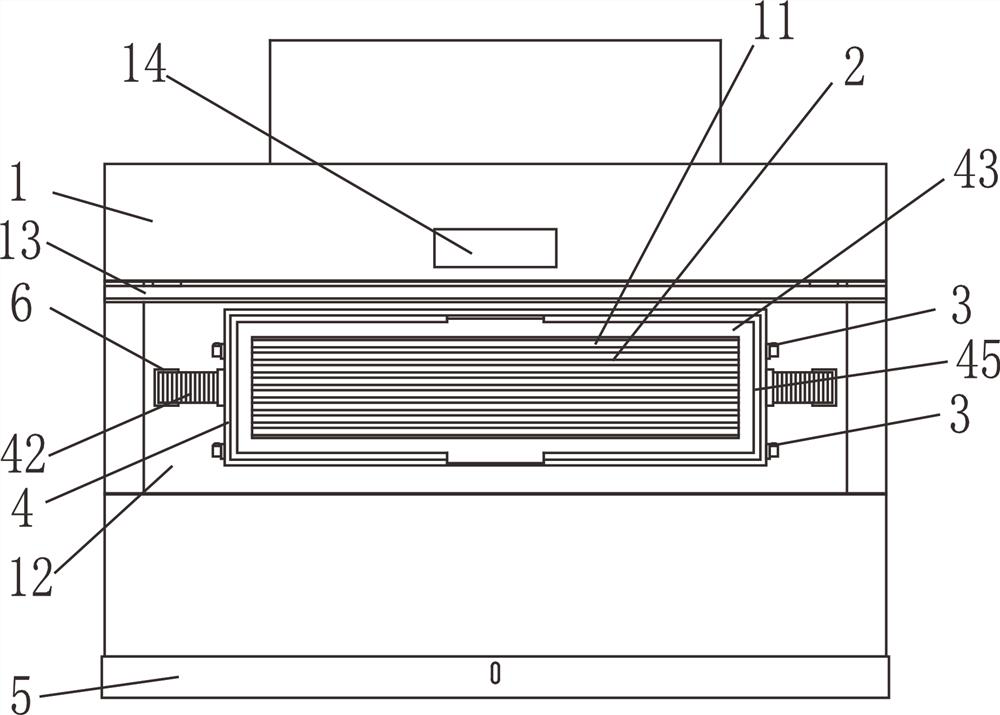

Openable and closable oil filtering barrier and range hood with same

ActiveCN112161309AReduce heating rateImprove oil filtration effectDomestic stoves or rangesLighting and heating apparatusProcess engineeringMechanical engineering

The invention discloses an openable and closable oil filtering barrier and a range hood with the same. The openable and closable oil filtering barrier is of a water cooling structure, the oil filtering effect is effectively improved, the oil filtering barrier can be controlled to be opened and closed, the range hood can suck oil fume in the same mode as a traditional range hood, an oil fume suction ring can extend out, the range hood sucks oil fume at a position closer to the oil fume generation position, does not influence the cooking sight and cause collision, can improve the oil fume suction efficiency, reduce the fan power and save energy, can be used for cooking for generating a large amount of oil fume, and can also be used for cooking for generating a small amount of oil fume; and an original oil fume suction port can be automatically opened and closed in the lifting process of the oil fume suction ring, and the oil filtering effect of the oil fume suction port is better.

Owner:绍兴依利奥厨具有限公司

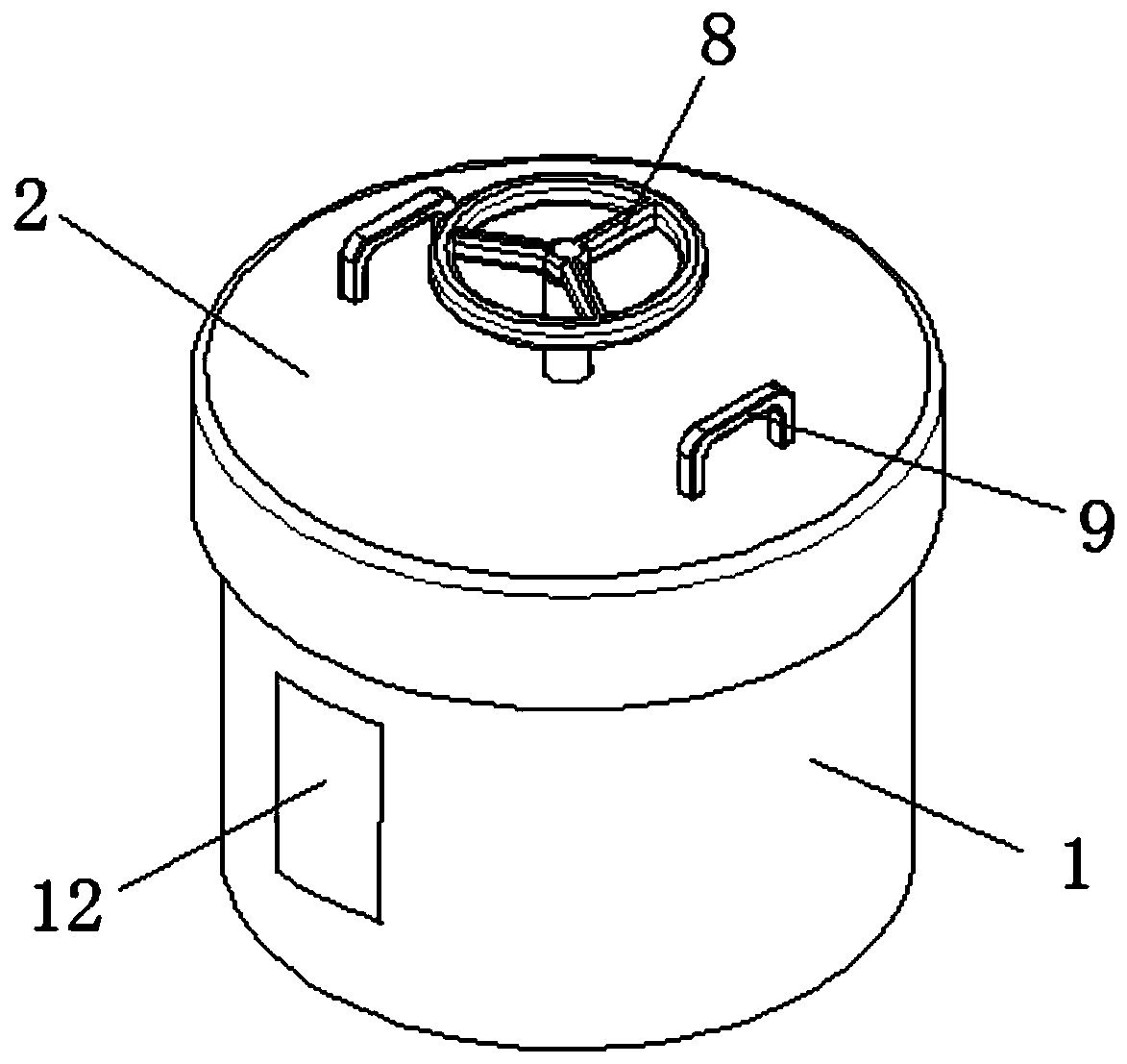

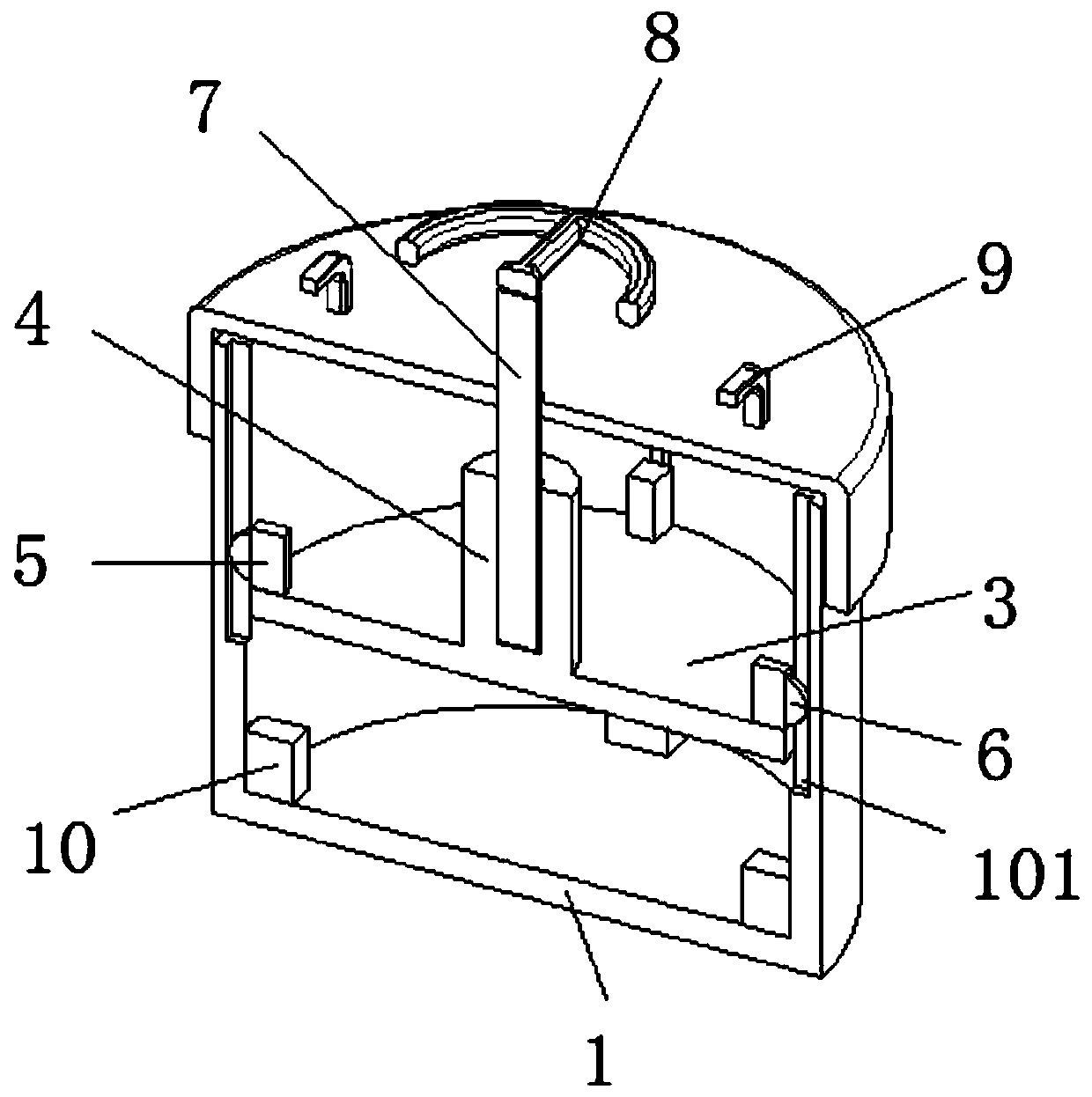

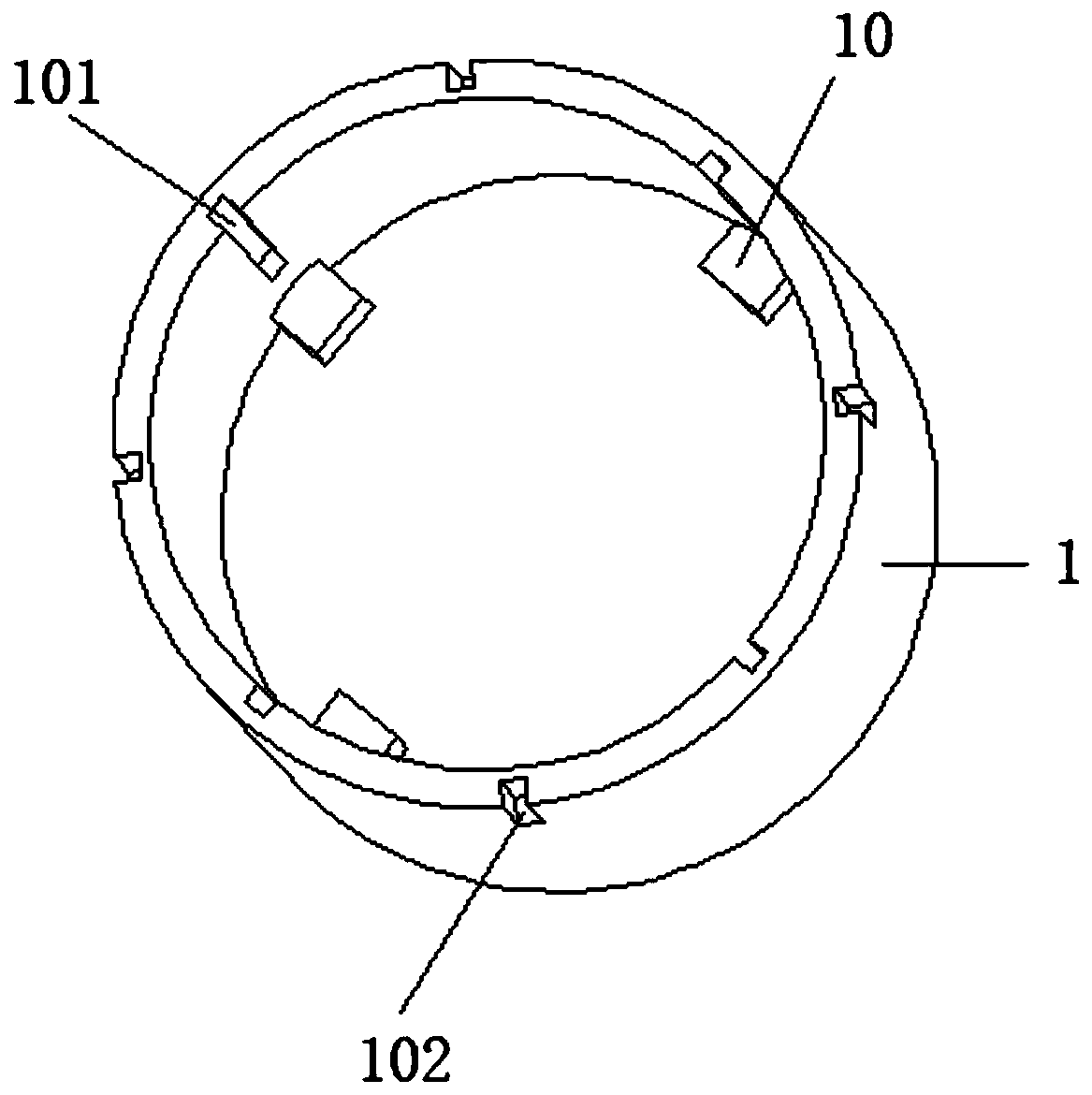

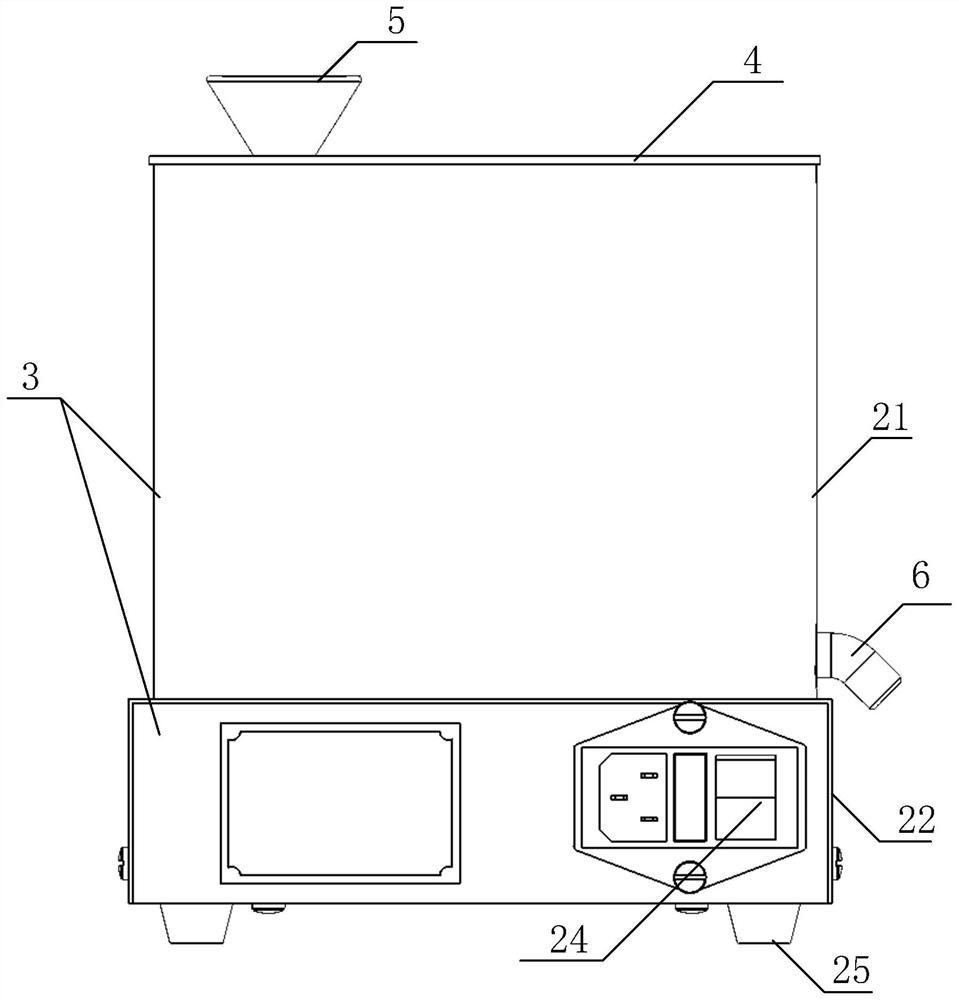

Oil filter

PendingCN112608789AIncreased oil filtration speedGood controllabilityFatty-oils/fats refiningMoving filtering element filtersElectric machineryProcess engineering

The invention discloses an oil filter, which comprises a motor, wherein a power output end is provided with a secondary filtering assembly in a detachable manner; a shell used for packaging the motor and the secondary filtering assembly; a cover body is detachably arranged at the upper end of the shell, wherein an oil inlet hopper matched with an oil outlet of the oil press is arranged on the cover body; and an oil outlet pipe matched with the secondary filtering assembly arranged on the shell. According to the oil filter provided by the invention, by designing the structure of the oil filter, compared with an existing oil filtering mode, the oil filter has a passive oil filtering effect and an active oil filtering effect, the oil filtering modes of the oil filter are remarkably different, and the oil filtering effect and the oil filtering efficiency can be effectively improved compared with the prior art; the oil filter can be adaptively applied to the matched oil filtering process of a large oil press and a small oil press, the oil product brightness after oil filtering can be improved by 20% or above, and the oil filtering speed is increased by 30% or above.

Owner:四川广鑫粮油机械制造有限公司

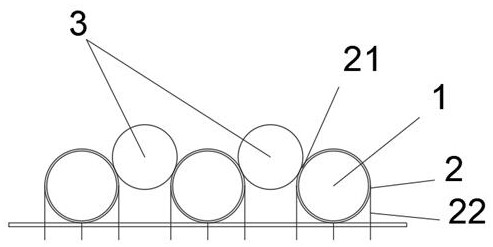

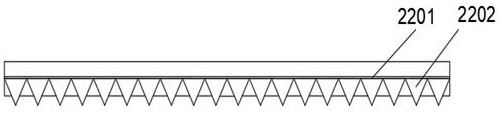

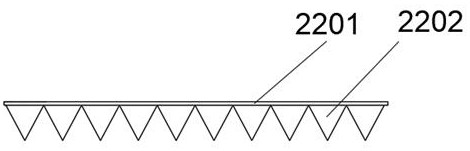

Conveying structure for steel ball oil filtering and oil filtering method thereof

PendingCN114042341AHigh speedImprove oil filtration effectStationary filtering element filtersSteel ballMechanical engineering

The invention discloses a conveying structure for steel ball oil filtering and an oil filtering method of the conveying structure. The conveying structure is composed of a supporting rod and an oil filtering mechanism. wherein the supporting rod is provided with an oil filtering mechanism, the oil filtering mechanism is provided with an oil sticking layer and oil guide suspensions, the oil sticking layer is connected with the supporting rod to support a conveyed steel ball, the top surfaces of the oil guide suspensions are connected with the oil sticking layer, and the oil guide suspensions are arranged at intervals in the length direction of the supporting rod. According to the oil filtering method, supporting rods of the conveying structure are arranged in parallel at intervals, steel balls at one ends of the supporting rods are conveyed in a rolling mode on the upper sides of the supporting rod intervals, and the supporting rods are obliquely arranged in a high-end and low-end mode, so that the steel balls can roll to the bottom ends from the top ends of the supporting rods under the gravity effect, and oil filtering is completed in the rolling process. According to the invention, the oil adsorbed by the oil sticking layer can be blocked, and oil is prevented from being guided from the top to the bottom of the supporting rod, so that the oil on the oil sticking layer is guided in time, and the oil filtering effect of the oil sticking layer is improved.

Owner:山东东阿鑫星钢球股份有限公司

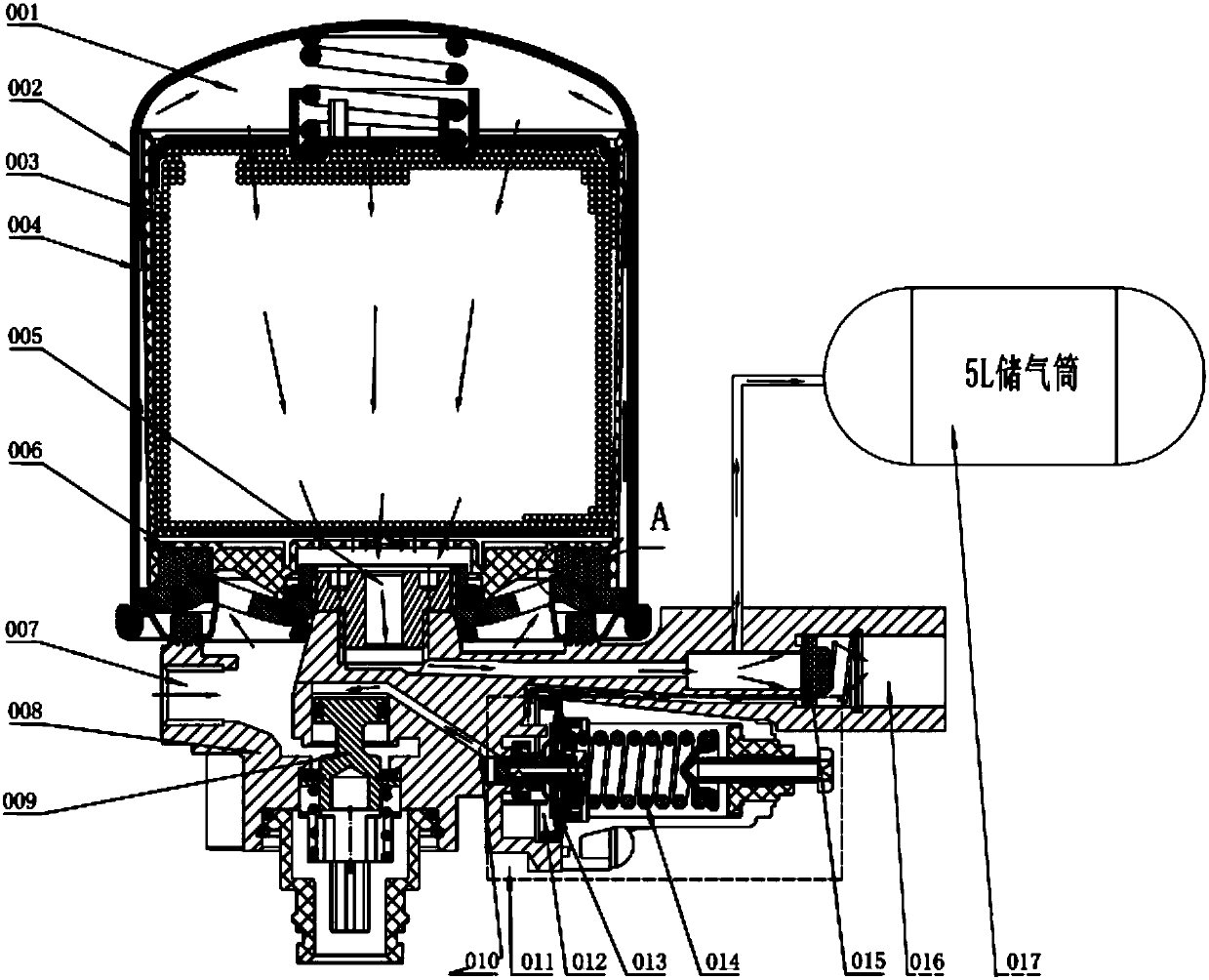

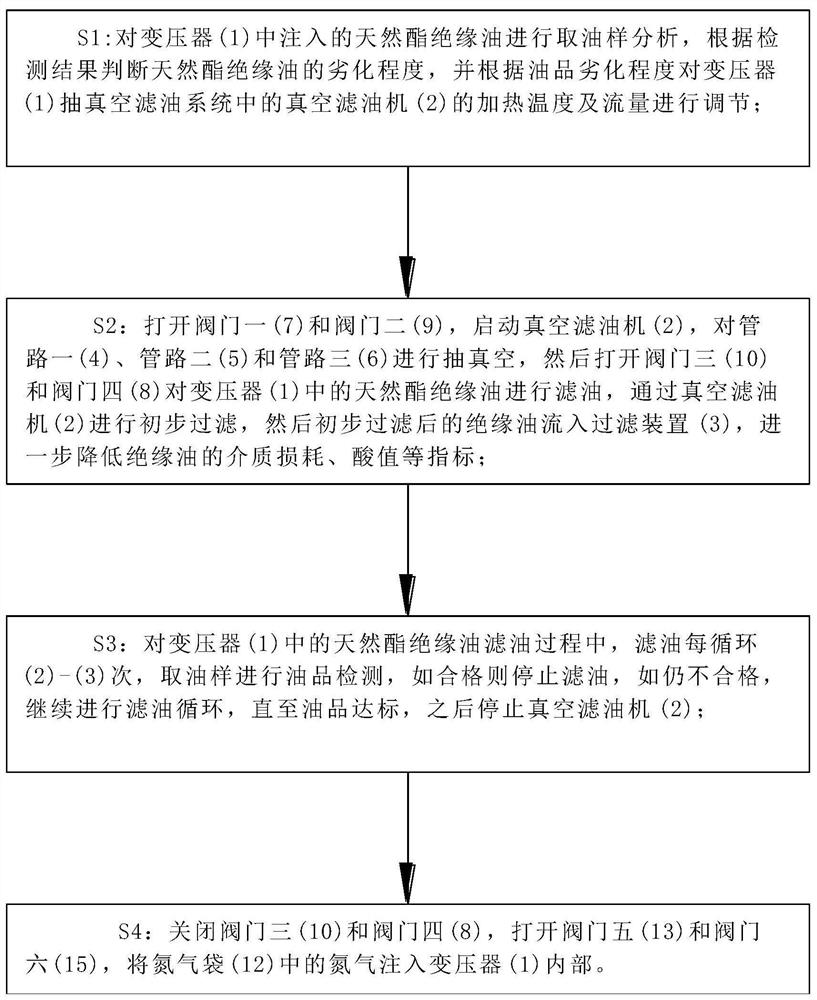

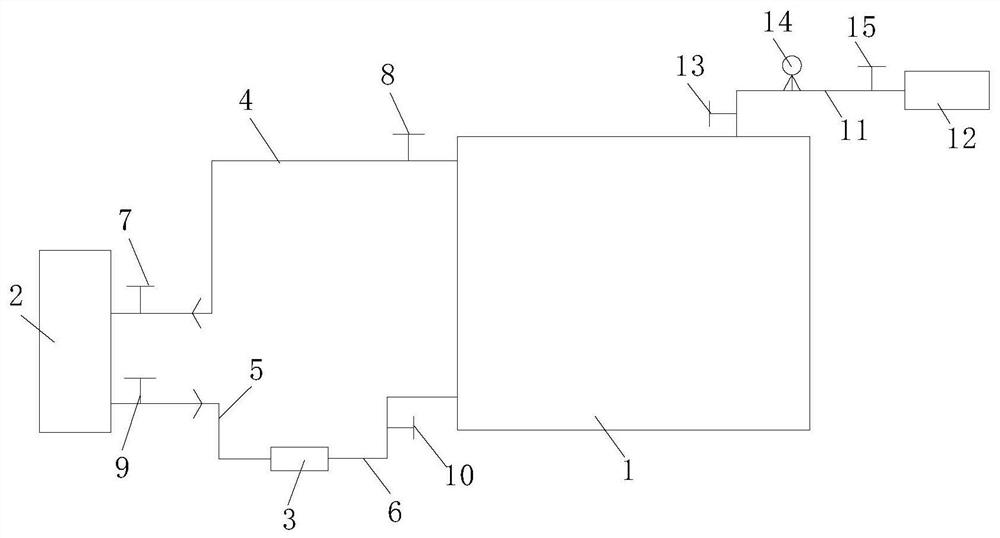

Oil filtering method for natural ester insulating oil transformer

PendingCN114093645AImprove oil filtration effectImprove efficiencyTransformers/inductances coolingInductances/transformers/magnets manufactureVacuum pumpingThermodynamics

The invention relates to the technical field of transformers, in particular to an oil filtering method for a natural ester insulating oil transformer. The oil filtering method comprises the following steps of: S1, carrying out oil sampling analysis on natural ester insulating oil injected into the transformer, judging the deterioration degree of the natural ester insulating oil according to a detection result, and adjusting the heating temperature and the flow of a vacuum oil filter in a vacuum pumping oil filtering system of the transformer according to the deterioration degree of an oil product; S2, opening a first valve and a second valve, starting a vacuum oil filter, vacuumizing a first pipeline, a second pipeline and a third pipeline, and then opening a third valve and a fourth valve to filter the natural ester insulating oil in the transformer. By carrying out preliminary filtering through using the vacuum oil filter, in the natural ester insulating oil filtering process, impurities of the natural ester insulating oil are reduced, the dielectric loss, an acid value and the like of the insulating oil are reduced, the oil quality is improved, and the oil injection efficiency is considered.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

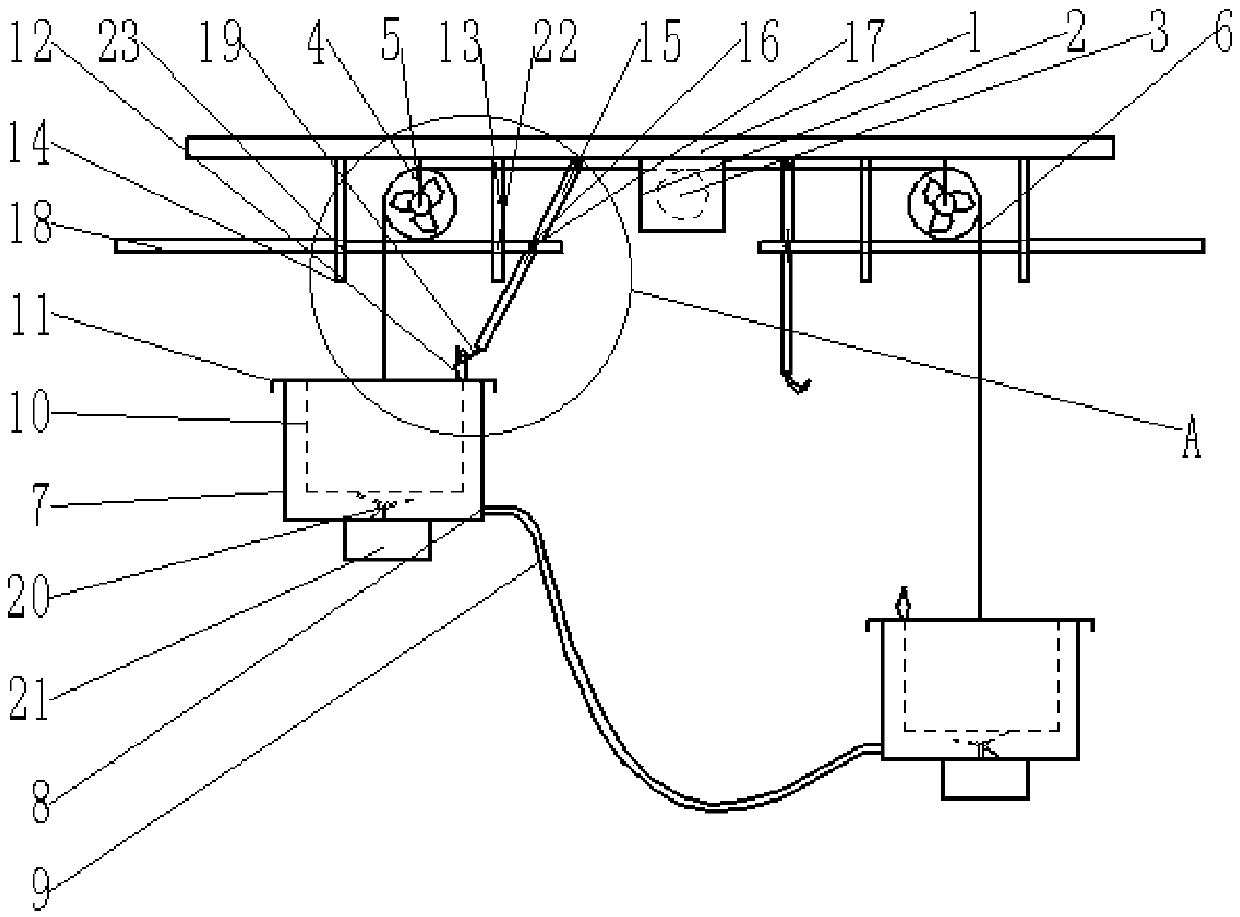

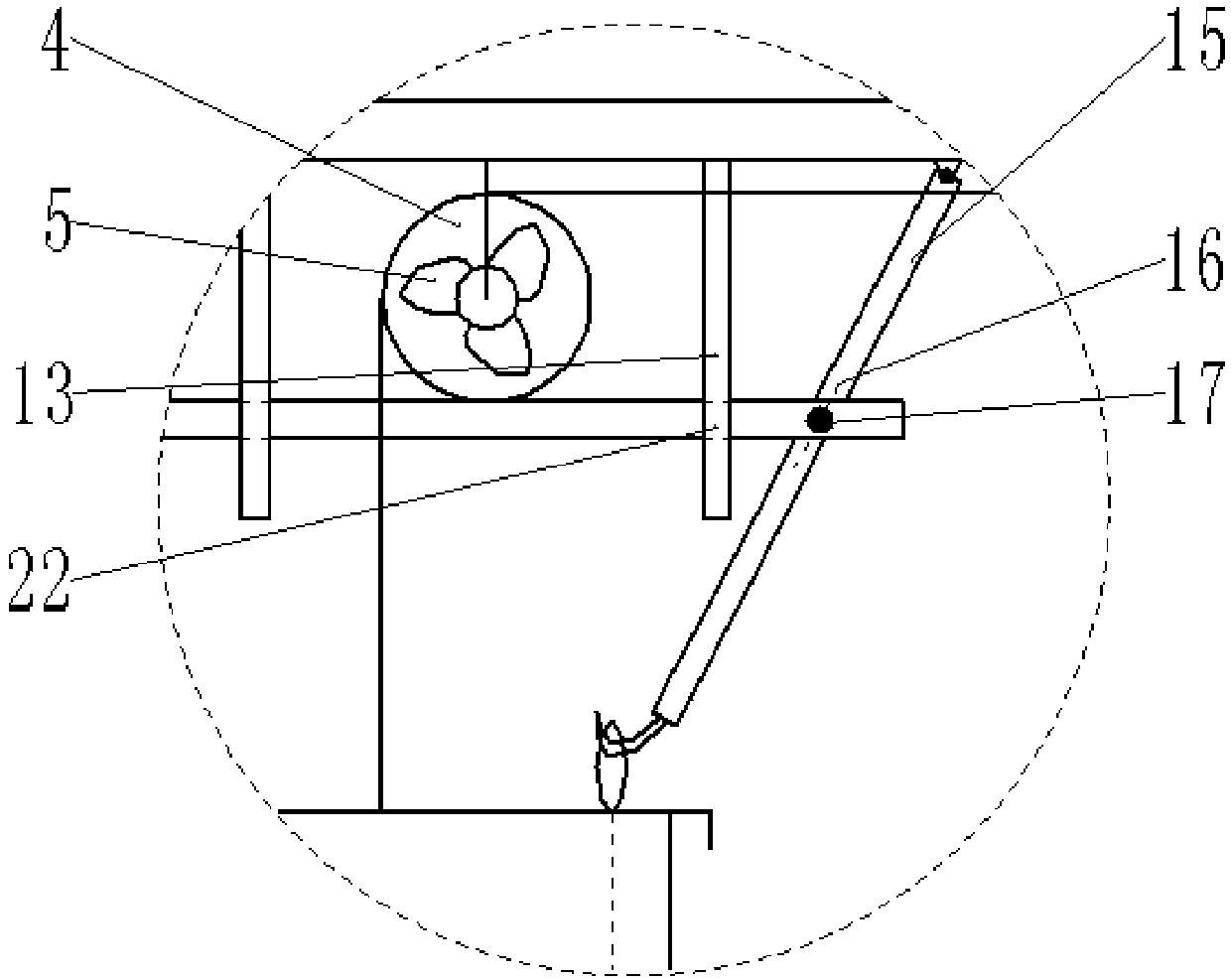

a range hood

ActiveCN112161310BImprove oil filtration effectLow powerDomestic stoves or rangesLighting and heating apparatusStructural engineeringRubber sheet

The invention discloses a range hood, which comprises a body, a fan and a control circuit board are arranged in the body, an oil suction mouth is arranged on the body, an oil filter barrier is arranged on the oil suction mouth, the oil filter barrier includes a frame and a The inner parallel oil filter fence, the frame is connected with the hollow oil filter fence, the frame and the oil filter fence are provided with cooling water, at least one side of the oil filter fence is open and an elastic rubber sheet is arranged on the opening, and the frame is opposite There are movable plugs on both sides, tension springs are arranged between the movable plugs, a first slope is arranged on the side of the movable plugs, an electric push rod is arranged on the body, and a hollow oil suction smoke ring is connected to the telescoping end of the electric push rod. An oil suction hole is arranged on the inner ring surface, and an oil suction pipe is arranged between the oil suction ring and the machine body. This kind of range hood can raise and lower the range hood according to needs, and can automatically open and close the original range hood during the lifting process, and makes the oil filtering effect of the oil filter compartment better.

Owner:绍兴依利奥厨具有限公司

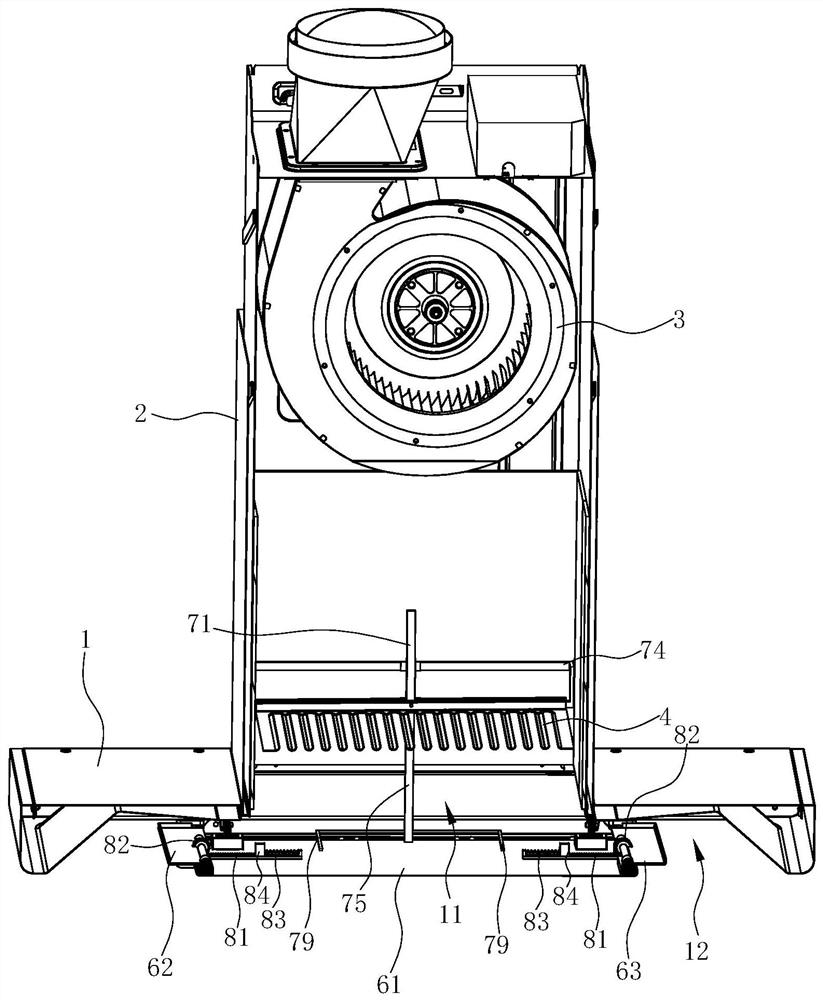

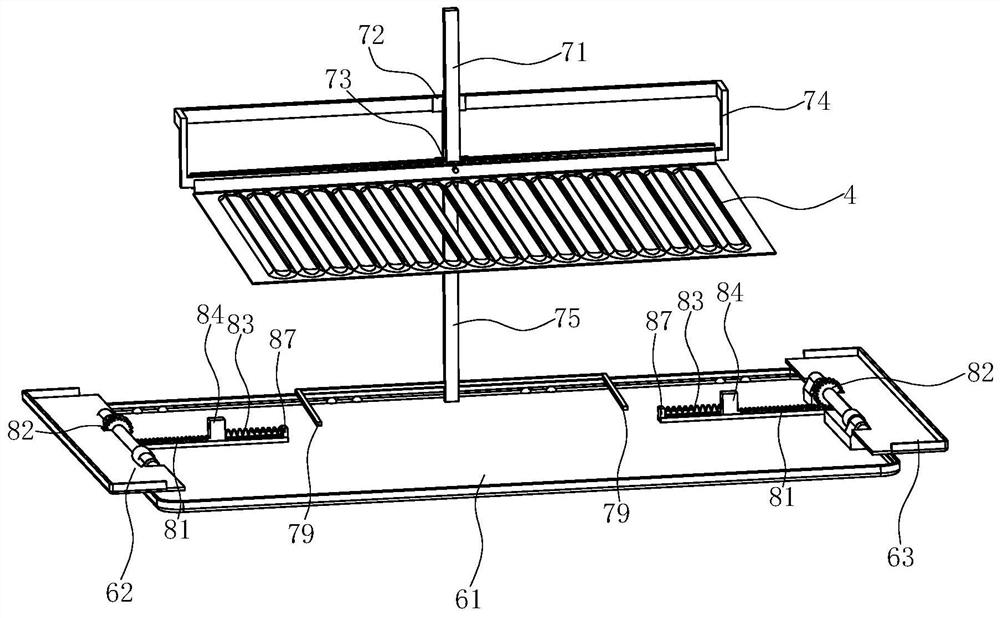

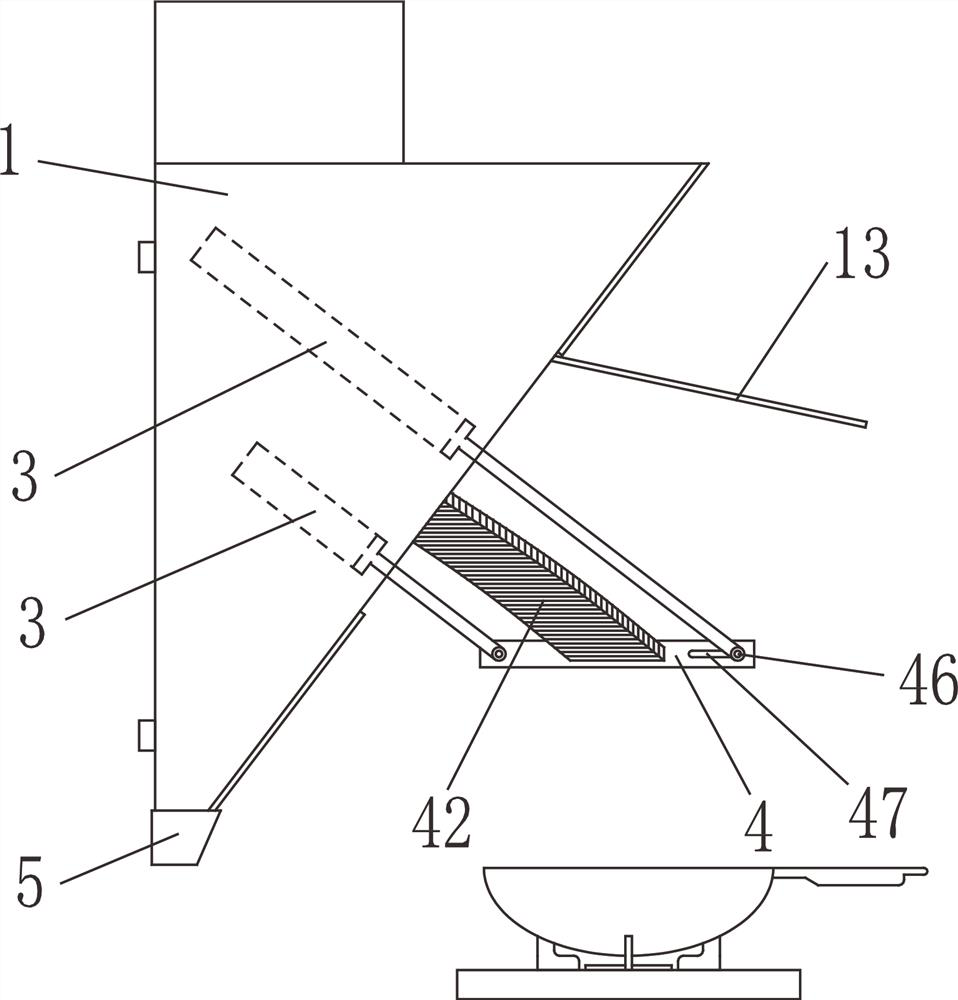

A range hood with a liftable range hood

ActiveCN112161311BImprove oil filtration effectGood oil filter effectDomestic stoves or rangesLighting and heating apparatusThermodynamicsGear wheel

The invention discloses a range hood with a liftable range hood, which comprises a machine body, a fan and a control circuit board are arranged in the body, an oil filter barrier is arranged on the range exhaust port of the body, and the oil filter barrier includes a frame and a filter The oil fence, the frame and the oil filter fence are connected in hollow, the frame and the oil filter fence are provided with cooling water, the oil filter fence is provided with an elastic rubber sheet, the frame is provided with a movable plug, and the movable plug is provided with a first Rack, there are double-layer gears rotating inside the body, an electric push rod is arranged on the body, a second rack is arranged on the telescopic rod of the electric push rod, the first rack and the second rack mesh with the double-layer gear, and the electric push rod The telescoping rod of the push rod is connected with an oil suction fume ring, and an oil suction fume pipe is arranged between the oil suction fume ring and the body. This range hood can raise and lower the oil suction smoke ring and automatically open and close the gap between the oil filter fence and the oil suction smoke pipe according to the needs, so as to improve the oil filtering effect.

Owner:绍兴依利奥厨具有限公司

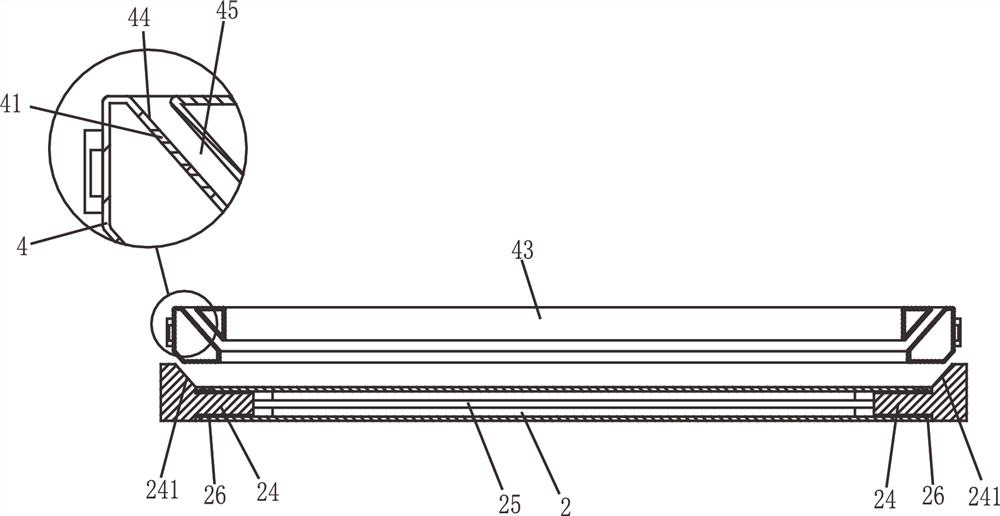

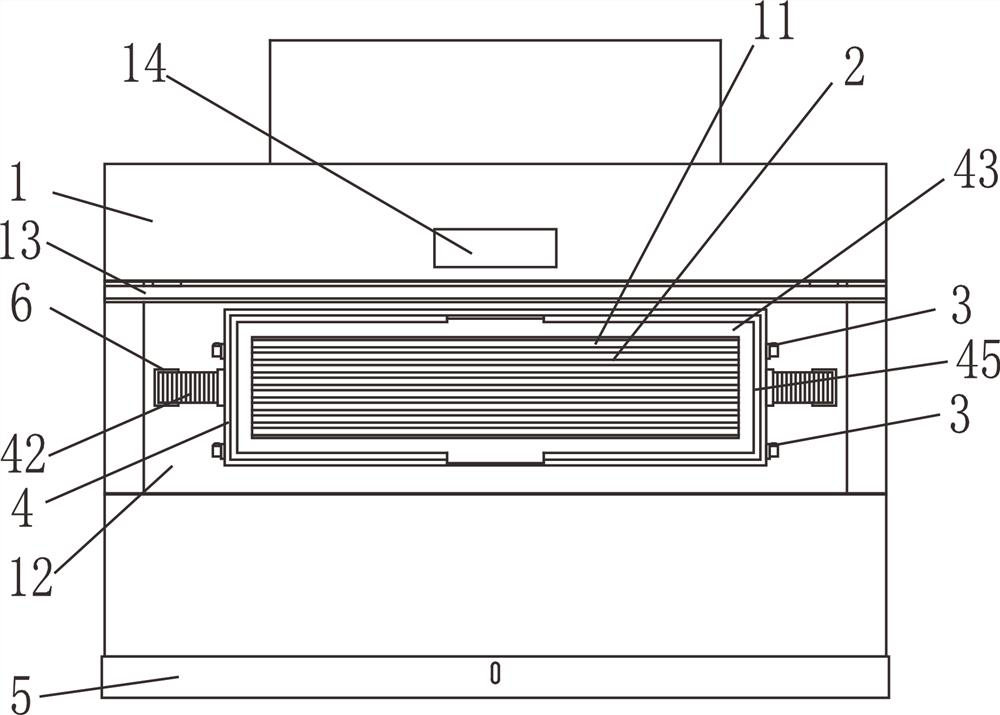

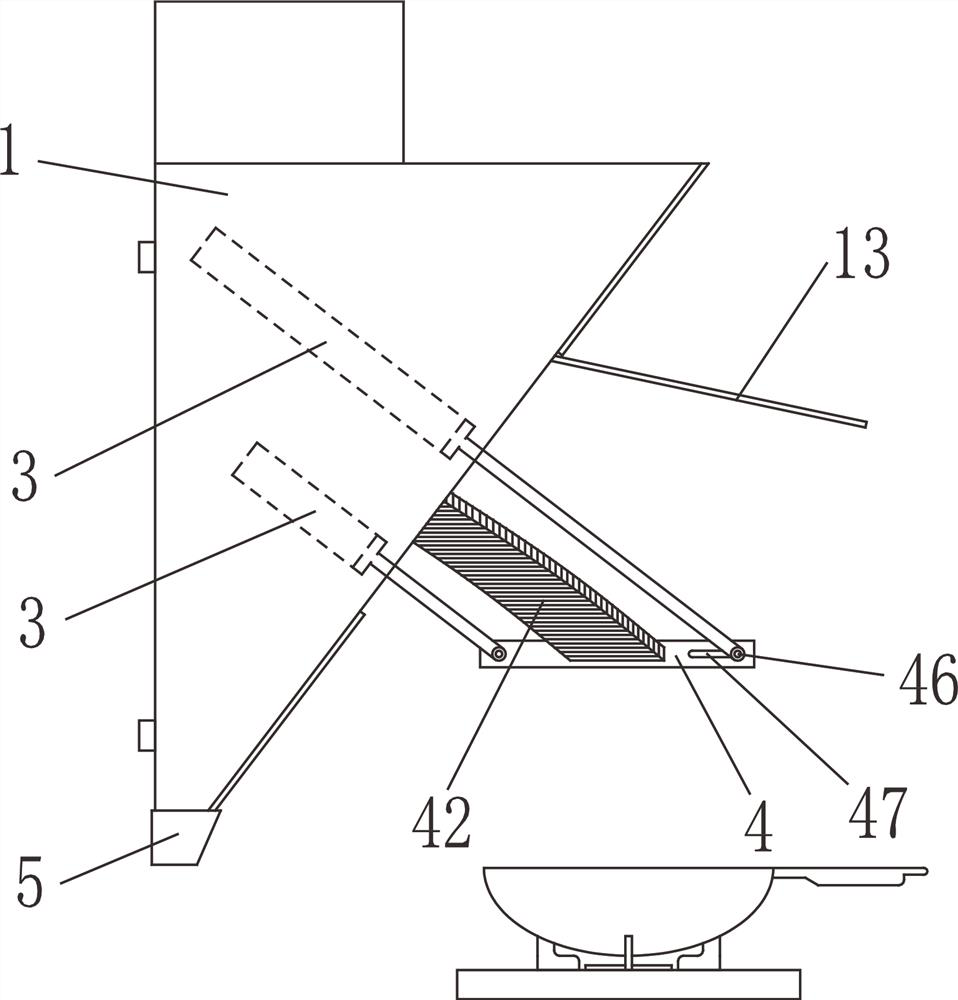

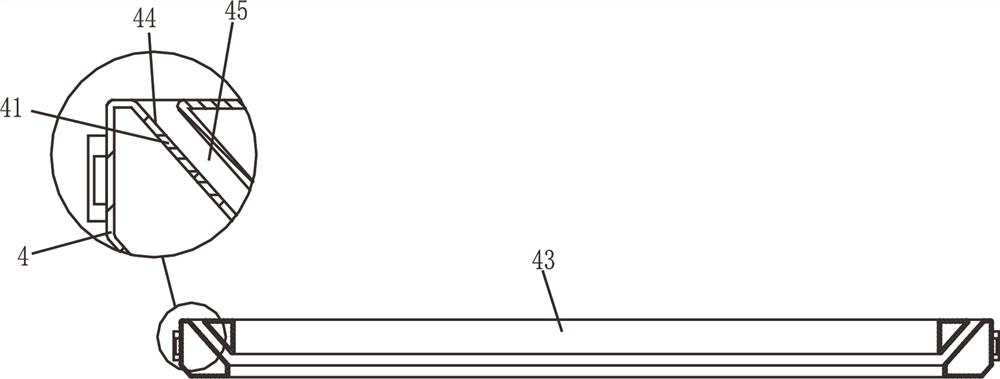

An oil filter device and a range hood using the device

ActiveCN104296212BImprove oil filtration effectDomestic stoves or rangesLighting and heating apparatusEngineeringMechanical engineering

An oil filter device comprises a framework and an oil filter assembly arranged on the framework, and is characterized in that the framework is provided with a condensing liquid influx and a condensing liquid outflux; a first pipeline provided for a condensing liquid to flow through is formed inside the framework; the oil filter assembly is provided with a second pipeline provided for the condensing liquid to flow through and communicated with the first pipeline; and the first pipeline and the second pipeline together constitute a connecting channel between the condensing liquid influx and the condensing liquid outflux. The invention also discloses a range hood applying the oil filter device. The oil filter device and the range hood have the advantages that the condensing liquid produced from a condensing unit flows in through the condensing liquid influx, flows through the first pipeline and the second pipeline and then flows out from the condensing liquid outflux, the temperature of the oil filter assembly can be lowered to 0 DEG C or less, cooking fumes are rapidly condensed into oil droplets on the surface of the oil filter assembly when passing through the oil filter assembly, and thus the oil filtering effect is improved; and when the range hood adopting the oil filter device works, the cooking fume emissions are significantly reduced, and the cooking fume sucking effect is significantly improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

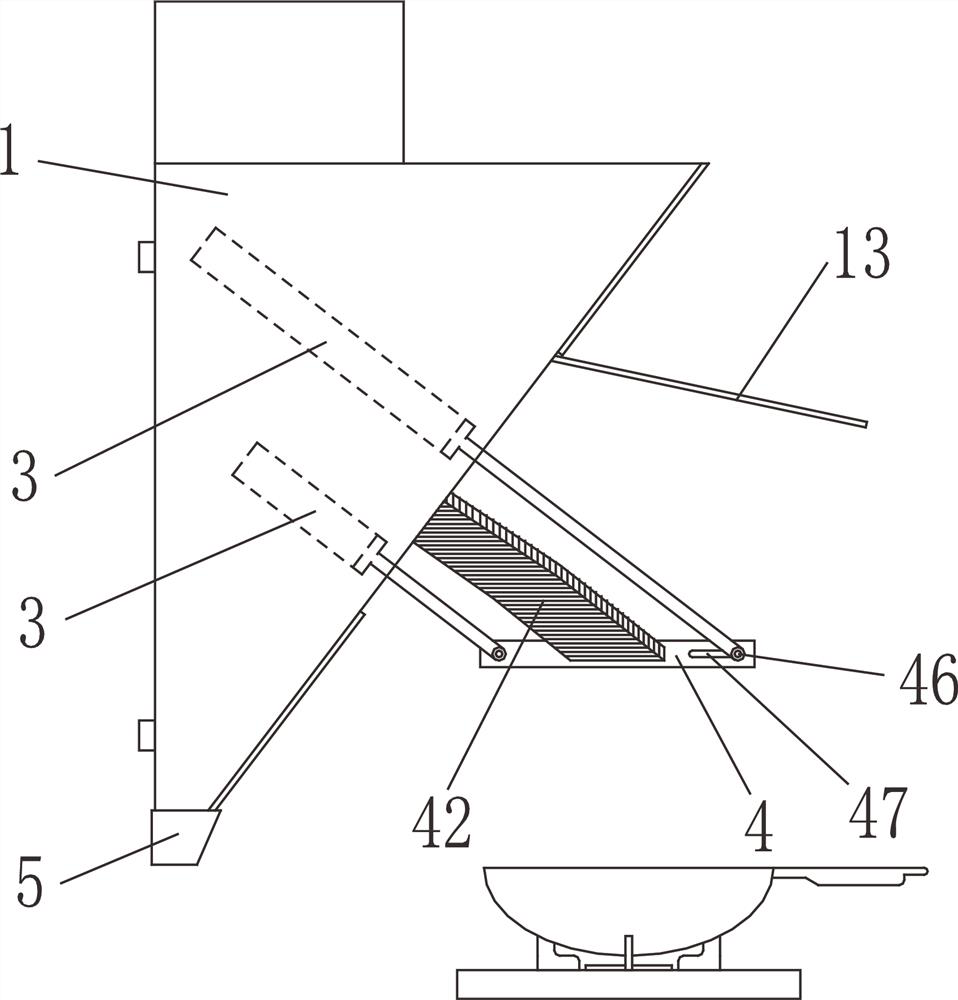

Range hood and control method thereof

PendingCN113834102AImprove oil filtration effectMeet multiple scenariosDomestic stoves or rangesLighting and heating apparatusStructural engineeringMechanical engineering

The invention discloses a range hood and a control method thereof. The range hood comprises a fume collecting hood, a draught fan frame arranged above the fume collecting hood and a draught fan system arranged in the draught fan frame, wherein an air inlet is formed in the fume collecting hood; a fume guide plate assembly is arranged below the air inlet, and the fume guide plate assembly comprises a main fume guide plate located in the middle; the range hood is characterized in that a movable filter screen is arranged below the draught fan system in the draught fan frame, and the movable filter screen can rotate around an axis extending front and back so as to face a left channel or a right channel in the draught fan frame; and the fume guide plate assembly further comprises a first auxiliary fume guide plate located at the left side of the main fume guide plate and a second auxiliary fume guide plate located at the right side of the main fume guide plate, and the first auxiliary fume guide plate and the second auxiliary fume guide plate can rotate around the axis extending front and back.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

An oil filter type range hood

ActiveCN104266243BImprove oil filtration effectIncrease contact areaDomestic stoves or rangesLighting and heating apparatusSoap bubbleExhaust fumes

The invention discloses an oil filter type range hood. The oil filter type range hood comprises a fan outer cover, an exhaust fume collecting hood, a filter screen and a rectifying plate arranged on the exhaust fume collecting hood and below the filter screen, wherein a fan is arranged in the fan outer cover, the range hood is characterized in that a bubble generator is arranged at an air inlet region between the rectifying plate and the filter screen, suction air current produced by the fan is matched with the bubble generator to product bubble blowing to the internal region between the rectifying plate and the filter screen. Compared with the prior art, the oil filter type range hood has the advantages that the bubble generator is arranged at an air inlet region between the rectifying plate and the filter screen, the fan can drive the airflow below the exhaust fume collecting hood to upward flow after bypassing the rectifying plate when being started, the airflow is blown to the bubble generator to enable the bubble generator to produce bubble, the contact area with the fume is increased by using the large surface area of the bubble, and the oil filter effect of the range hood is promoted by using the soluble performance of liquid soap to the grease under the condition of using the soap bubble.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Workpiece oil immersion device

ActiveCN107716209AAccelerate evaporationSpeed up the oil filterLiquid surface applicatorsCoatingsSprocketRust

The invention discloses a workpiece oil immersion device and relates to the field of rust prevention. The workpiece oil immersion device comprises a suspension beam, a motor, a first chain wheel and second chain wheels. The motor is arranged on the suspension beam. The first chain wheel is arranged on the motor. Suspension rods, first positioning rods, the second chain wheels and second positioning rods are sequentially arranged towards the two sides from the motor on the suspension beam. The suspension rods are hinged to the suspension beam, and the suspension rods are provided with sliding grooves and hooks. Sliding shafts are arranged in the sliding grooves, and the hooks are arranged on the lower sides of the suspension rods. The second chain wheels are coaxially fixedly provided withgears, racks are engaged with the lower sides of the gears, and the racks are rotationally connected with the sliding shafts. The second chain wheels are fixedly provided with fan blades. The first chain wheel is engaged with a chain, and the chain is engaged with the second chain wheels. The two ends of the chain are fixedly connected with oil barrels, oil holes are formed in the lower sides of the oil barrels, and the oil holes communicate with each other through a hose. Net pockets are arranged in the oil barrels, rope sleeves are arranged at opening portions of the net pockets, the rope sleeves are arranged outside the oil barrels, and the rope sleeves can be hooked by the hooks. By means of the workpiece oil immersion device, air can be blown towards the interiors of the oil barrels for accelerating oil filtering, the efficiency is improved, the net pockets are hooked out of the barrels automatically after oil filtering is over, the structure is simple, and operation is simplified.

Owner:重庆达小丰机械有限公司

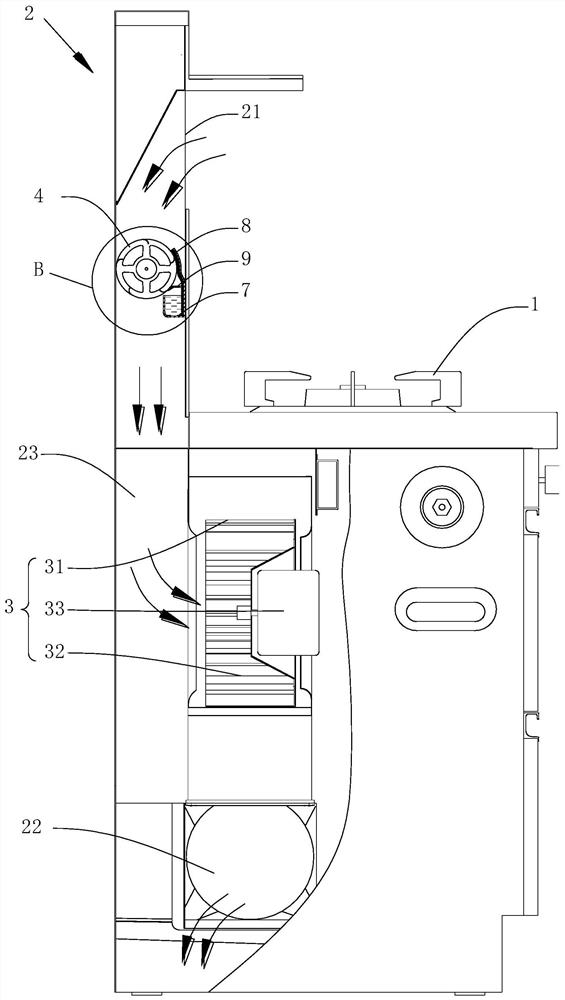

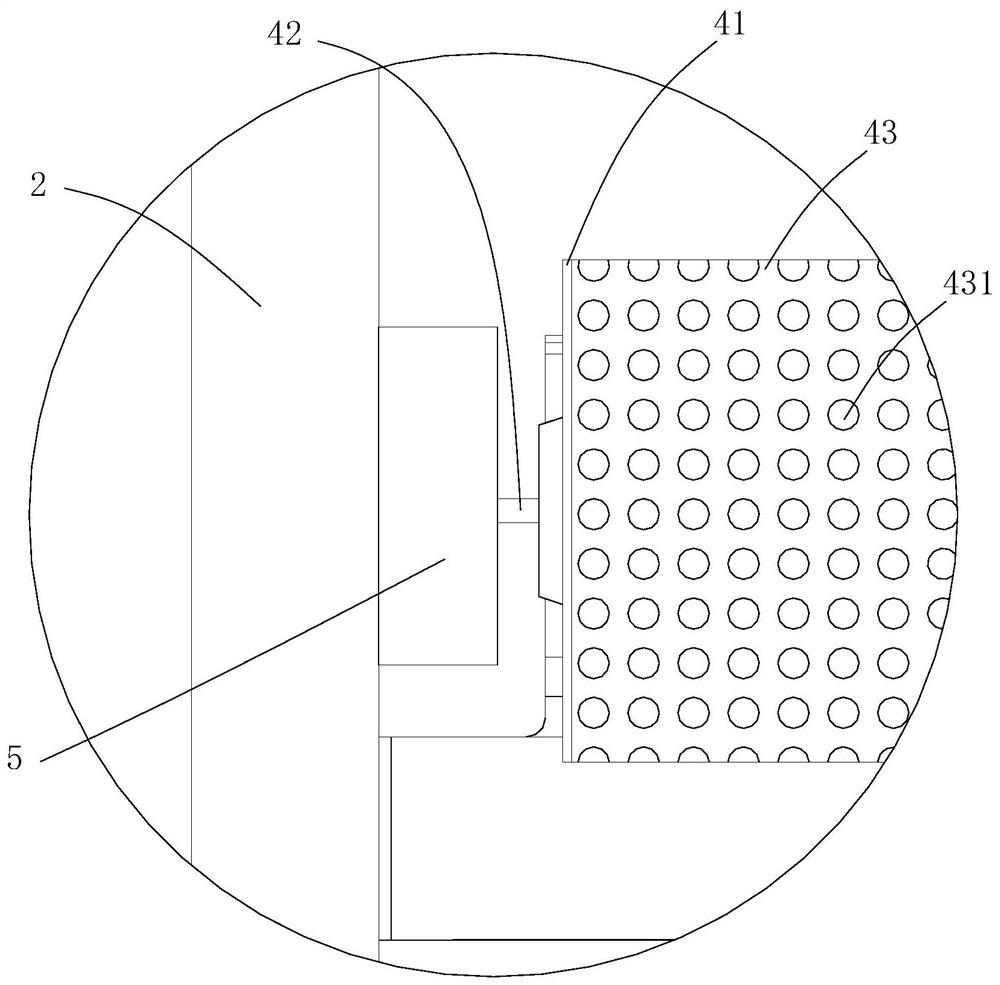

Integrated cooker

PendingCN114110681AImprove oil filtration effectEasy to cleanDomestic stoves or rangesDispersed particle filtrationProcess engineeringCooker

The invention belongs to the technical field of electrical equipment, and particularly provides an integrated stove which comprises a stove body and a range hood which are integrally arranged, and the range hood comprises a shell, a smoke exhaust channel, a smoke exhaust fan and a smoke exhaust fan, the oil smoke filtering device comprises a filtering component, the filtering component is of a cylindrical structure, and the filtering component is arranged in the smoke discharging channel and can rotate relative to the shell; a liquid storage member; on one hand, the adsorption component extends into the liquid storage component and can adsorb the cleaning liquid in the liquid storage component to the adsorption component, and on the other hand, the adsorption component can abut against the outer wall of the filtering component, so that a liquid film is formed on the surface of the filtering component on the basis of abutting in the process that the filtering component rotates relative to the shell. Through the arrangement, when oil fume penetrates through the liquid film, grease in the oil fume is captured by the liquid film, so that the oil filtering effect of the filtering component can be improved, and in the operation process, the adsorption component can continuously absorb cleaning liquid from the liquid storage component to supplement the cleaning liquid.

Owner:QINGDAO HAIER WISDOM KITCHEN APPLIANCE CO LTD +1

An oil fume filter with primary effect filtering function

ActiveCN109373385BExtend the motion pathReduced filtering effect is affectedDomestic stoves or rangesLighting and heating apparatusStructural engineeringControl theory

The invention discloses a lampblack filter with a primary filter function, and belongs to the field of lampblack purifying devices. The lampblack filter comprises an air box; an air sucking port and an intake port are arranged on the top wall and the side wall of the air box; a first oil filter frame and a second oil filter frame, buckled with each other, are arranged in the intake port; multiplefirst guide plates bent into the air box are arranged on opposite side walls of the first oil filter frame and the second oil filter frame in parallel; two ends of the first guide plates are connectedwith second guide plates inwards bent; and the first guide plates and the second guide plates on the first oil filter frame are staggered from the first guide plates and the second guide plates on the second oil filter frame to form zigzag lampblack channels. The lampblack filter achieves the following effects: as oil drops in lampblack can be stopped, the oil drops are not easy to directly enterthe filter.

Owner:SUZHOU ZHAOHE ENVIRONMENT & ENERGY TECH CO LTD

Range hood with liftable oil fume suction ring

ActiveCN112161311AImprove oil filtration effectGood oil filter effectDomestic stoves or rangesLighting and heating apparatusGear wheelMachine

The invention discloses a range hood with a liftable oil fume suction ring. The range hood comprises a machine body, a draught fan and a control circuit board are arranged in the machine body, an oilfiltering barrier is arranged on an oil fume suction opening of the machine body, the oil filtering barrier comprises a frame and an oil filtering barrier plate, the frame is in communication with theoil filtering barrier plate in a hollow mode, cooling water is arranged in the frame and the oil filtering barrier plate, an elastic rubber sheet is arranged on the oil filtering barrier plate, a movable plug is arranged on the frame, a first rack is arranged on the movable plug, a double-layer gear is rotationally arranged in the machine body, an electric push rod is arranged on the machine body, a second rack is arranged on a telescopic rod of the electric push rod, the first rack and the second rack are meshed with the double-layer gear, the telescopic rod of the electric push rod is connected with an oil fume suction ring, an oil fume suction pipeline is arranged between the oil fume suction ring and the machine body, and the electric push rod stretches to control opening and closingof an oil filtering barrier plate gap and the oil fume suction pipeline. The range hood can lift the oil fume suction ring and automatically open and close the oil filtering fence plate gap and the oil fume suction pipeline as required, so that the oil filtering effect is improved.

Owner:绍兴依利奥厨具有限公司

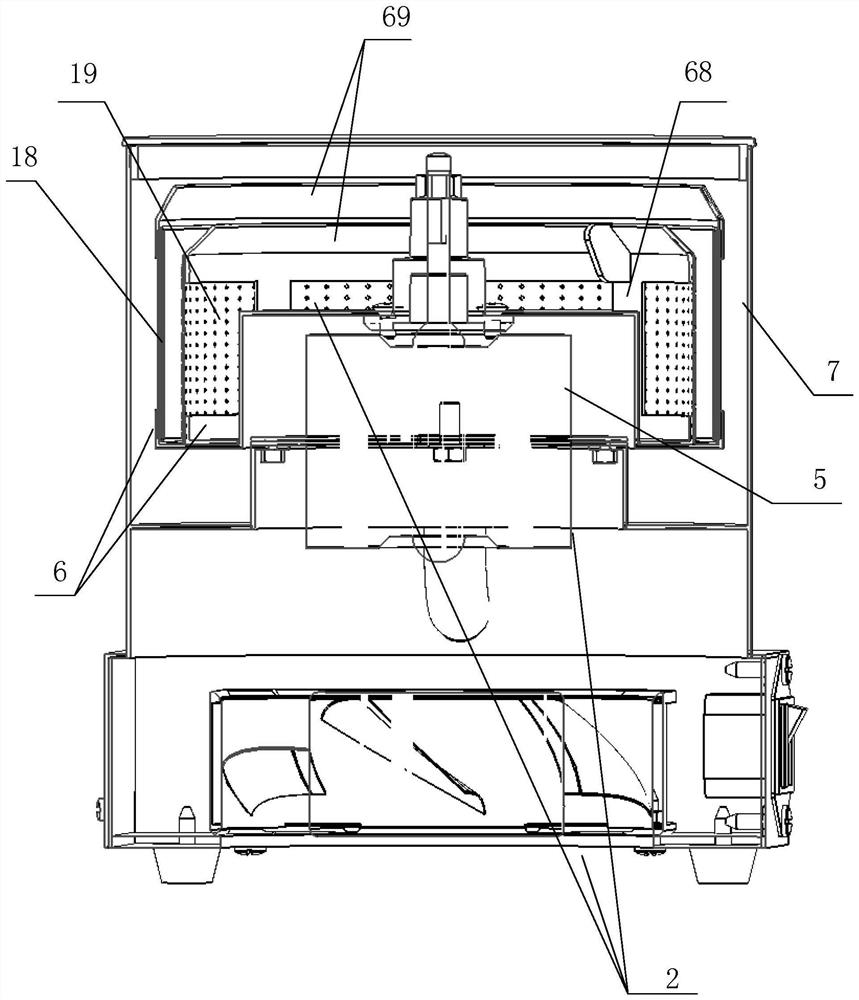

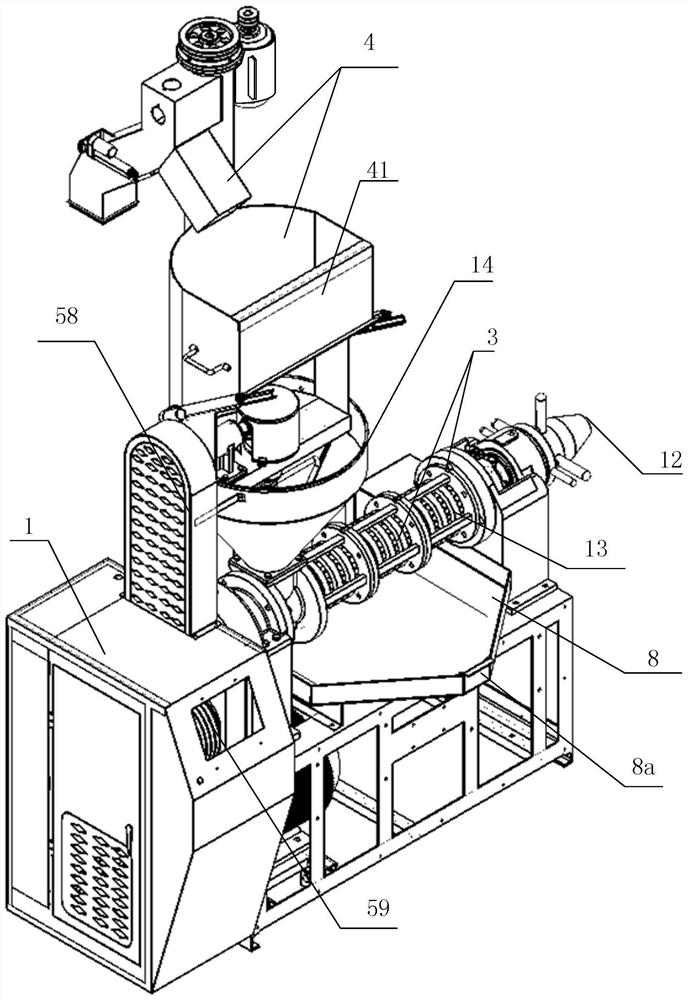

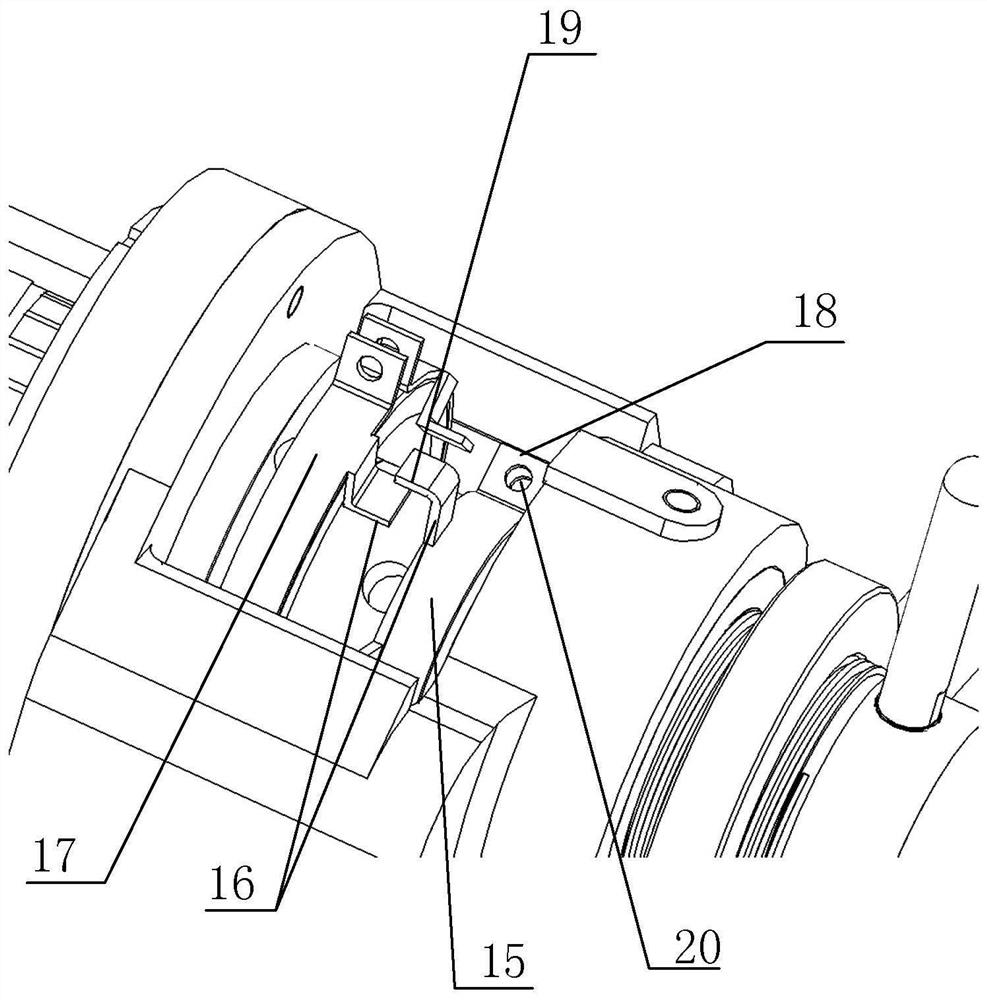

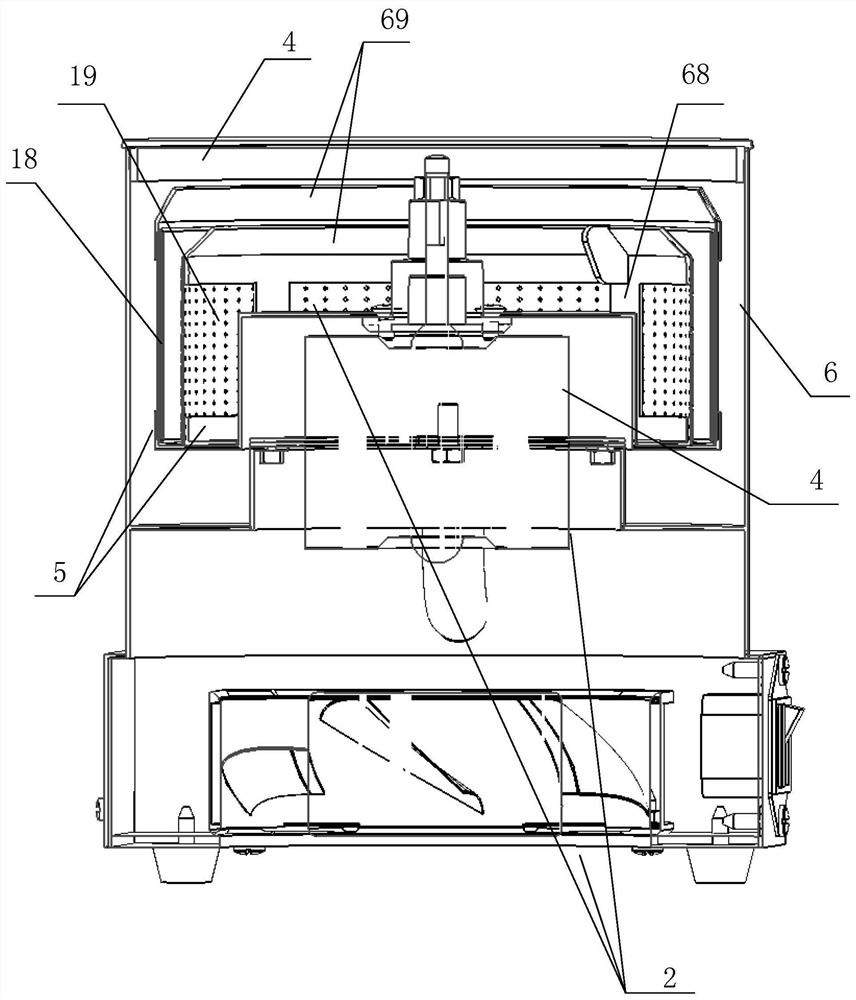

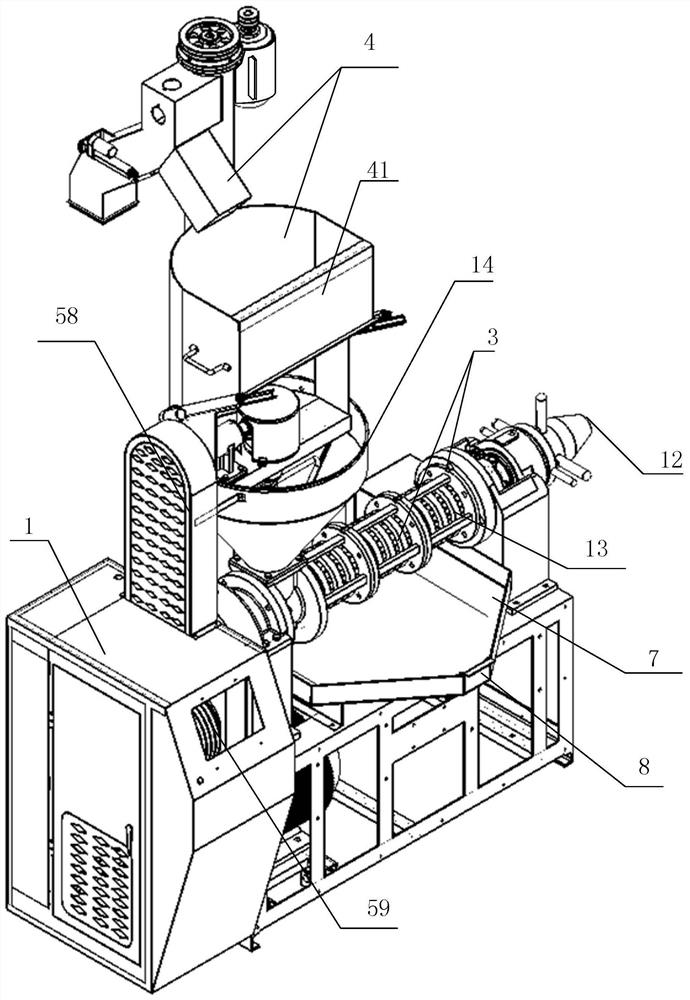

Oil extraction system

ActiveCN112590280BImprove filtering effectContinuous operationFatty-oils/fats refiningFatty-oils/fats productionElectric machineryProcess engineering

The invention discloses an oil extraction system, which comprises an oil extraction machine and an oil filter matched with the oil extraction machine; The feed end and the discharge end cooperate to form a feeding unit for feeding and extracting material circulation; the oil filter is configured to include: a motor, the power output end of which is detachably provided with a secondary filter assembly; The casing for encapsulating the motor and secondary filter components. The invention provides an oil pressing system. Compared with the prior art, the pressing and filtering are integrated, the filtering effect is better, the filtering speed is better, and the finished oil is clearer.

Owner:四川广鑫粮油机械制造有限公司

Oil pressing system

ActiveCN112590280AGood filtering effectEnsure continuity and completenessFatty-oils/fats refiningFatty-oils/fats productionProcess engineeringMechanical engineering

The invention discloses an oil pressing system. The oil pressing system comprises an oil press and an oil filter matched with the oil press; the oil press is configured to include a cage bar-type barcage used for realizing pressing operation, and a feeding unit cooperating with a feeding end and a discharging end of the cage bar-type bar cage to form a feeding and pressing cycle; and the oil filter is configured to include a motor and a shell, wherein the power output end of the motor is detachably provided with a secondary filtering assembly; and the shell is used for packaging the motor andthe secondary filtering assembly. Compared with the prior art, the oil pressing system provided by the invention has the advantages that pressing and filtering are integrated, the filtering effect isbetter, the filtering speed is higher, and finished oil is clearer.

Owner:四川广鑫粮油机械制造有限公司

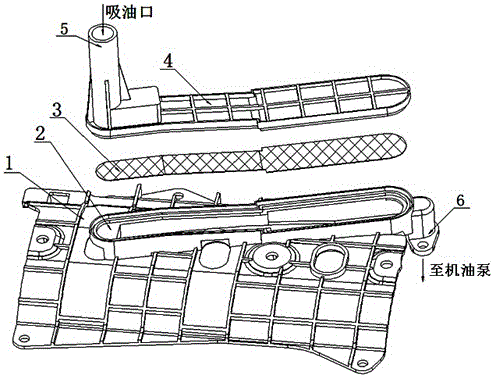

Sump strainer

InactiveCN105041422ALight in massLarge filter areaLubricant mounting/connectionPressure lubricationSump

The invention discloses a sump strainer which comprises a sump partition plate, an oil duct lower sheet and a filter screen, wherein an oil duct upper sheet is arranged on one surface of the sump partition plate; an oil outlet is formed at one end of the oil duct upper sheet; the oil duct upper sheet is internally provided with a groove; the filter screen and the oil duct lower sheet are mounted in the groove of the oil duct upper sheet from the inside out sequentially; and an oil inlet of the oil duct lower sheet and the oil outlet of the oil duct upper sheet are staggered mutually. According to the sump strainer, the sump partition plate and the oil duct upper sheet are integrated, the oil duct lower sheet and the filter screen are directly mounted in the oil duct upper sheet, and the strip sheet-shaped filter screen is adopted, so that a filter area is increased and the oil straining effect is improved; and with the adoption of the integrated structure, the mass of parts is reduced greatly and the production cost is also reduced.

Owner:JIANGXI CHANGHE AUTO

An openable and closable oil filter compartment and a range hood with the oil filter compartment

ActiveCN112161309BImprove oil filtration effectReduce heating rateDomestic stoves or rangesLighting and heating apparatusThermodynamicsOil filter

The invention discloses an openable and closable oil filtering barrier and a range hood with the oil filtering barrier. The openable and closable oil filtering barrier has a water-cooling structure, which effectively improves the oil filtering effect and can control the oil filtering effect. The partition is opened and closed, this range hood can not only absorb the range hood in the same way as the traditional range hood, but also can extend the range hood to absorb the range hood closer to the position where the range hood is generated, without affecting the cooking line of sight and causing collisions , can improve the efficiency of the range fume, reduce the power of the fan, and save energy. It can be used not only for cooking that generates a large amount of fume, but also for cooking that generates a small amount of fume. Moreover, the original range fume can be automatically opened and closed during the lifting process of the fume ring. mouth, and makes the oil filtering effect of the range hood better.

Owner:绍兴依利奥厨具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com