Oil filter device and range hood applying same

A technology of oil filtering device and range hood, which is applied in the application, removal of oil fume, household stoves, etc. It can solve the problems of increased resistance, reduced air volume, and inapplicability of range hoods, so as to improve the oil filtering effect, reduce oil fume, Improve the effect of oil smoke effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

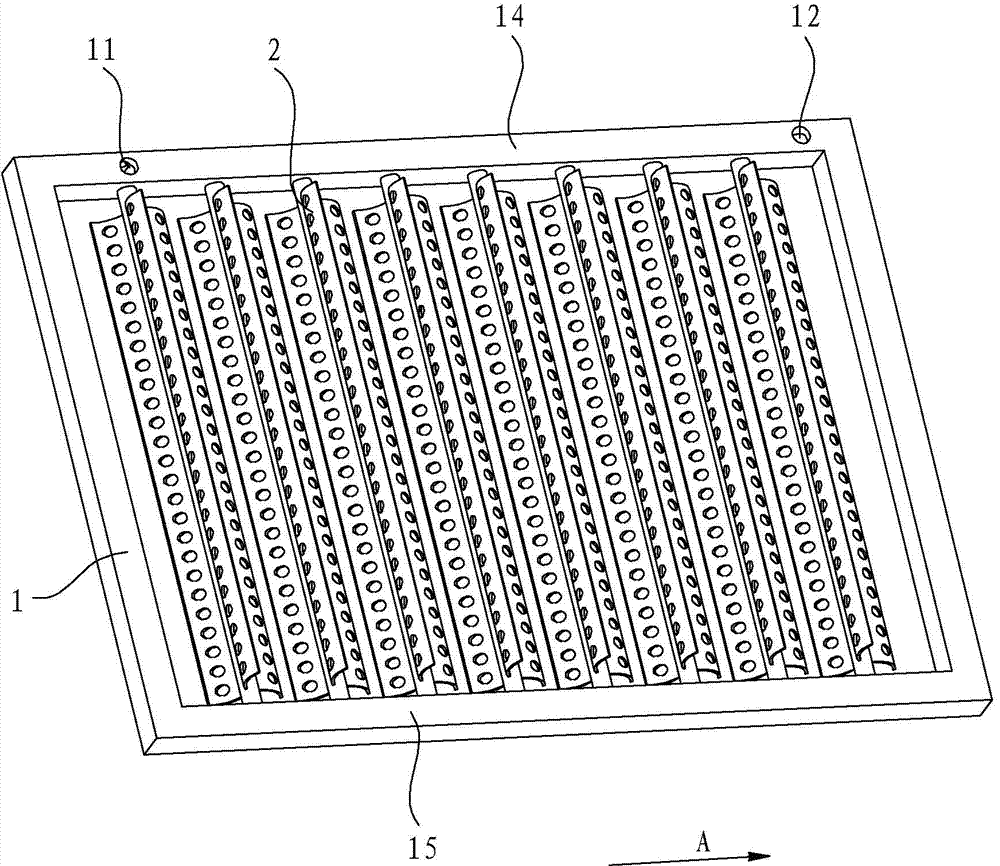

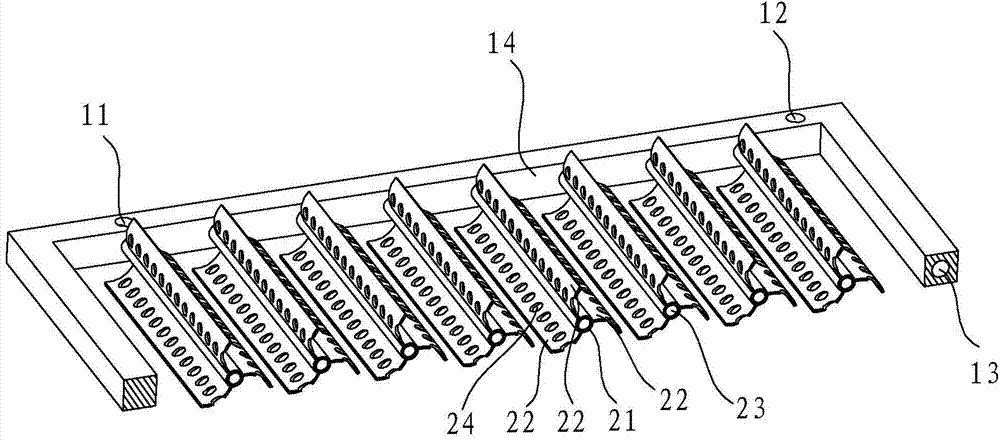

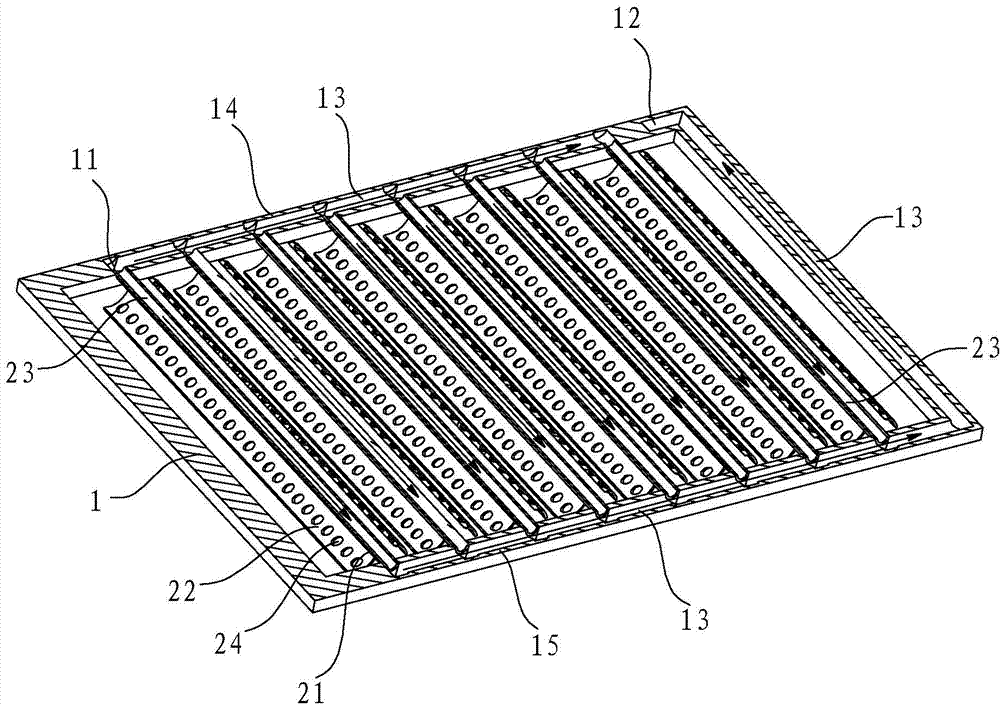

[0024] Such as Figure 1 to Figure 3 shown in figure 1 The direction indicated by the straight arrow A is right. The oil filtering device in this embodiment includes a square frame 1 and an oil filtering assembly installed on the frame. The front frame rod 14 of the frame 1 is provided with a condensate inflow port 11 and a condensate outflow port 12, and a supply port is formed inside the frame 1. The first pipeline 13 through which the condensate flows. The oil filter assembly is a plurality of oil filter units 2 arranged in sequence on the frame 1. Specifically, each oil filter unit 2 includes a rotating shaft 21 and an oil filter sheet 22 installed on the rotating shaft. The inside of the rotating shaft 21 is hollow to A second pipeline 23 communicating with the first pipeline 13 is formed. The two ends of the rotating shaft 21 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com