Conveying structure for steel ball oil filtering and oil filtering method thereof

A technology for filtering oil and steel balls, which is applied in separation methods, chemical instruments and methods, fixed filter element filters, etc. It can solve the problems of kerosene attached to the surface of steel balls, slow processing procedures, and slow oil filtration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with embodiment, further illustrate the present invention.

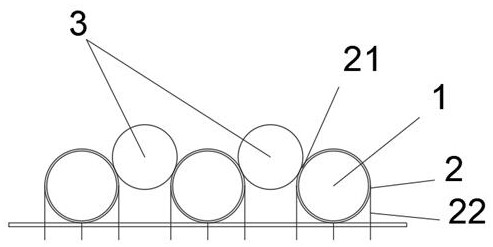

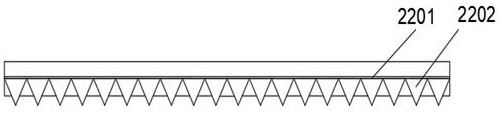

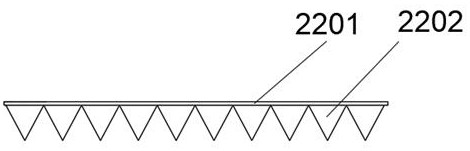

[0031] see Figure 1-Figure 4 It can be seen that a delivery structure for steel ball oil filtering of the present invention is composed of a strut 1 and an oil filtering mechanism 2; the strut 1 is provided with an oil filtering mechanism 2, and the oil filtering mechanism 2 is provided with a viscous oil layer 21 , oil guide suspension 22, sticky oil layer 21 is connected with pole 1 to support the steel ball 3 being transported, the top surface of oil guide suspension 22 is connected with sticky oil layer 21, oil guide suspension 22 is arranged at intervals along the length direction of pole 1.

[0032] The support rod 1 is set parallel to the support rod 1 at intervals, and the steel ball 3 at one end of the support rod 1 is rolled and transported on the upper side of the support rod 1 interval. It can be rolled from the top of the pole 1 to the bottom. During the rolling process, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com