Oil filtering method for natural ester insulating oil transformer

A technology for transformers and insulating oil, applied in the field of transformers, can solve problems such as low oil filtration efficiency and poor oil filtration effect, and achieve the effects of improving filtration efficiency, improving the quality of insulating oil, and improving the overall oil quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

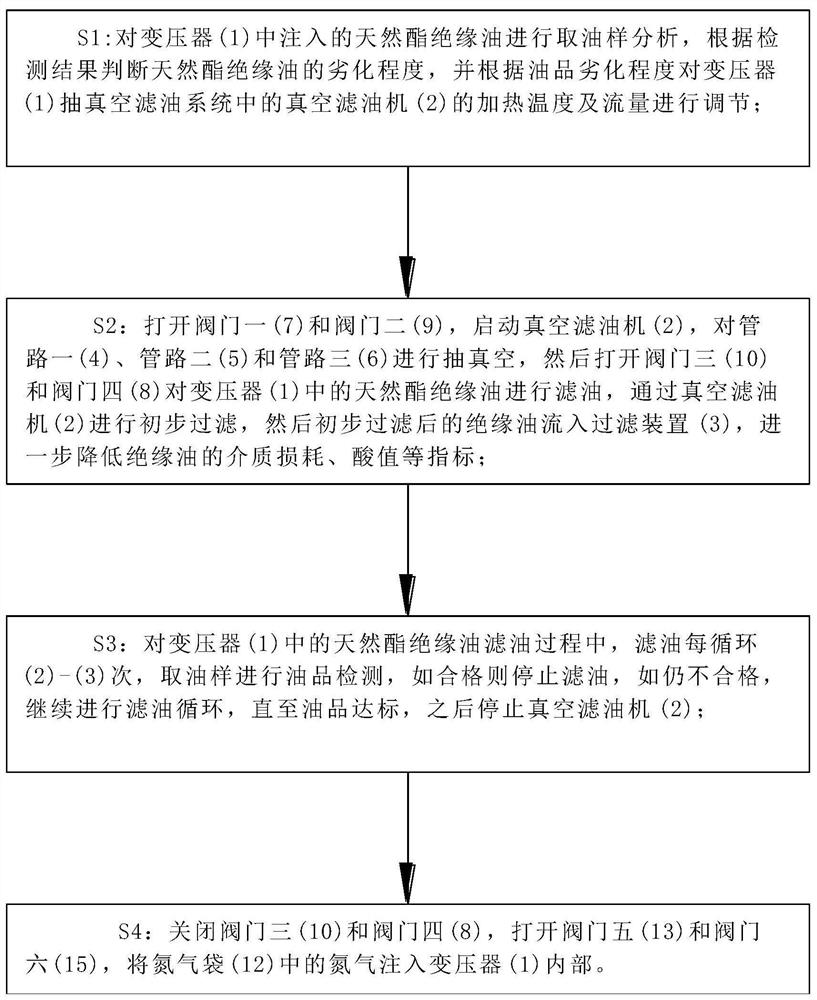

[0031]see Figure 1-5 Shown, a kind of oil filtering method that is used for natural ester insulating oil transformer, this method comprises the following steps:

[0032] S1: Take oil samples and analyze the natural ester insulating oil injected into transformer 1, judge the degree of deterioration of the natural ester insulating oil according to the test results, and vacuum the oil filter in the vacuum oil filter system of transformer 1 according to the degree of oil deterioration 2 to adjust the heating temperature and flow rate;

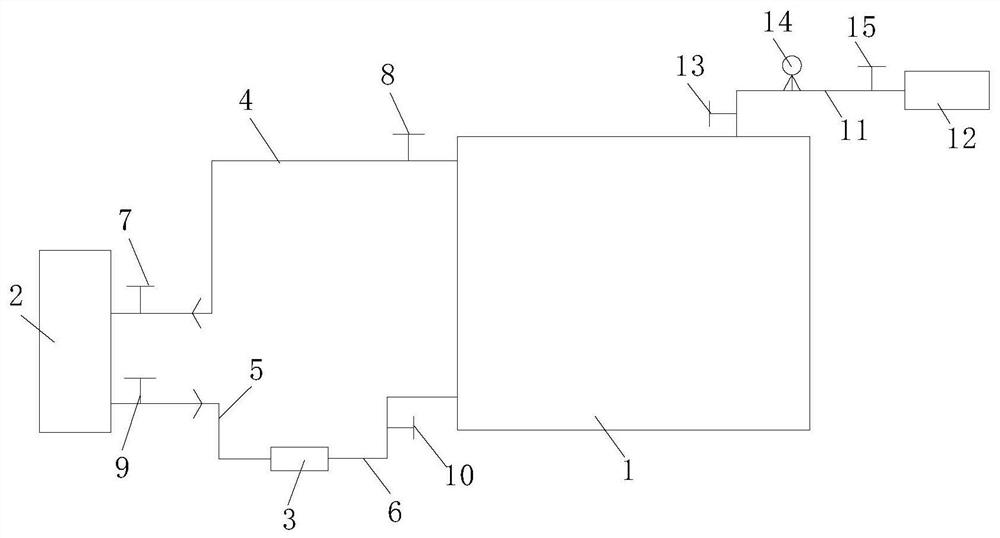

[0033] S2: Open valve 1 7 and valve 2 9, start vacuum oil filter 2, vacuumize pipeline 1 4, pipeline 2 5 and pipeline 3 6, then open valve 3 10 and valve 4 8 to transformer 1 The natural ester insulating oil is filtered, and the vacuum oil filter 2 is used for preliminary filtration, and then the pre-filtered insulating oil flows into the filter device 3 to further reduce the dielectric loss, acid value and other indicators of the insulating oil;...

Embodiment 2

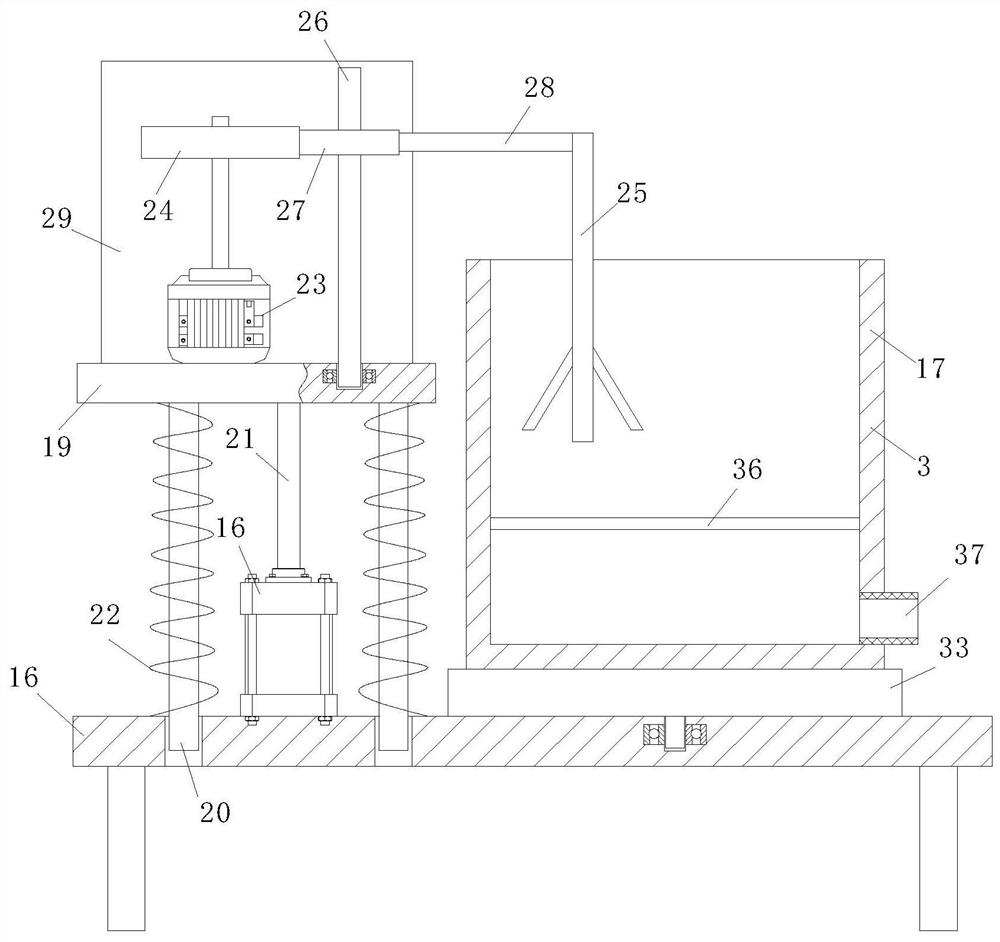

[0044] see Image 6 As shown in Comparative Example 1, as another embodiment of the present invention, a deflector 38 is affixed to the inner side wall of the bottom of the filter bucket 17; during operation, the setting of the deflector 38 has better guiding function, so that the insulating oil at the bottom of the filter barrel 17 can flow along the deflector 38 and flow out from the discharge pipe 37 to realize the collection of the insulating oil.

[0045] Working principle: Open valve 1 7 and valve 2 9, start vacuum oil filter 2, vacuumize pipeline 1 4, pipeline 2 5 and pipeline 3 6, then open valve 3 10 and valve 4 8 to transformer 1 The natural ester insulating oil in the oil is filtered, and impurities such as moisture, large particles, and dissolved gases in the insulating oil in the natural ester insulating oil transformer 1 are removed through the vacuum oil filter 2 to achieve the effect of preliminary filtration, and then after preliminary filtration The insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com