electronic cigarette nozzle

An electronic cigarette and smog technology, applied in the field of electronic cigarettes, can solve the problems of smooth oil introduction process, hot hands, increased manufacturing costs, etc., and achieve the effects of saving production costs, simplifying production processes, and good oil filtering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

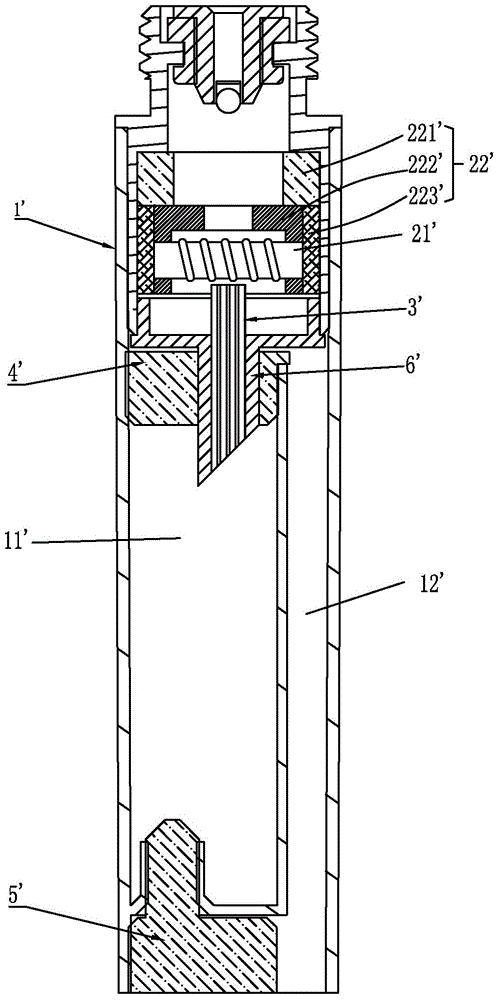

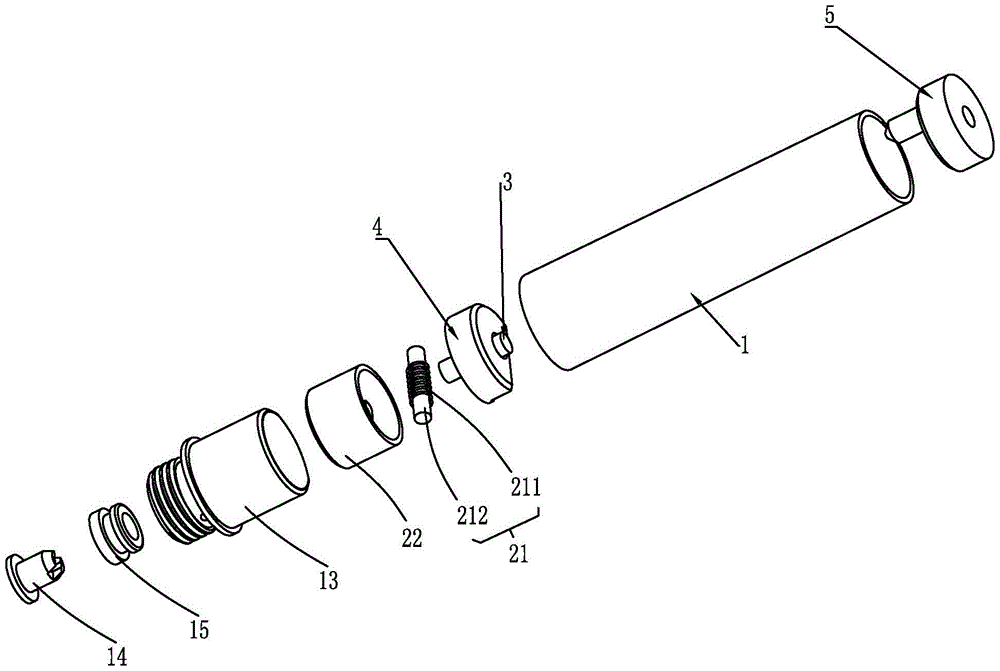

[0027] Such as Figures 2 to 8 As shown, the present invention provides an electronic cigarette suction nozzle and its oil filter device, including a suction tube 1, an atomizing device, an oil guide tube 3, a smoke oil plug 4, and an oil filter containing a smoke oil cap 5 or a smoke oil cap 5". device.

[0028] The suction tube 1 includes an e-liquid bin 11, a smoke channel 12, a connector 13, an electrode part 14, and an insulating ring 15. The e-liquid bin 11 is arranged in the suction tube 1. The suction tube 1 is integrally formed, and the smoke oil tank 11 is used to store liquid smoke oil. One end of the smoke oil tank 11 is provided with the smoke oil plug 4, and the other end is provided with the smoke oil cap 5. The smoke oil plug 4 and The e-liquid cap 5 together seals the e-liquid in the e-liquid chamber 11 . The smoke channel 12 is the channel through which the smoke generated by the atomization of the smoke oil by the atomization device 3 passes to the suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com