A pipeline robot suitable for detection of multi-branch pipeline network

A pipeline robot, multi-branch technology, applied in the direction of pipes/pipe joints/fittings, special pipes, pipe components, etc., can solve the problems of poor bending ability, unable to actively turn, unable to meet the detection requirements of complex branch pipe network, etc. The effect of increasing the load capacity, reducing the space and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

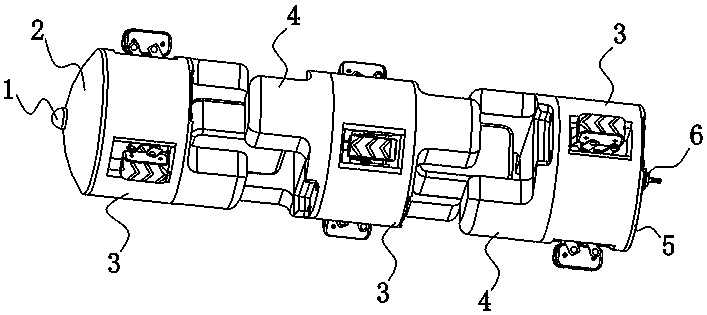

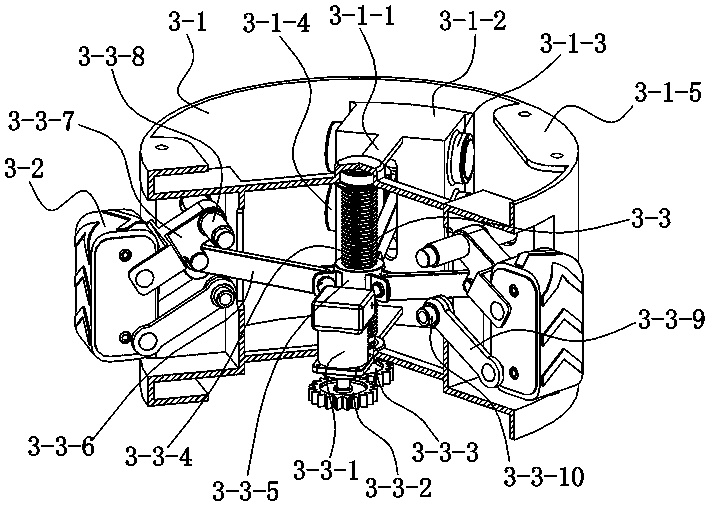

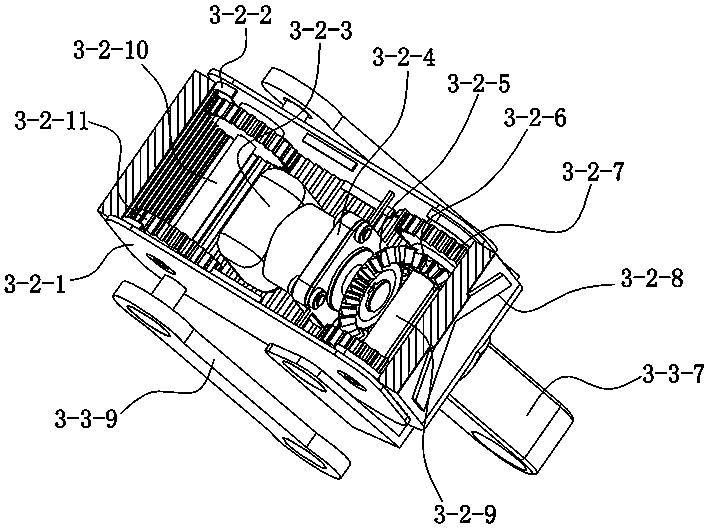

[0021] Such as figure 1 As shown, a pipeline robot suitable for multi-branch pipeline network detection includes at least two sections of drive knuckles 3 and at least one section of steering knuckles 4, and the adjacent two driving knuckles 3 are connected by steering knuckles 4. A front end cover 2 is fixed on the front end surface of the section 3, and a sensor 1 for detecting the distribution of the pipe network pipeline path is installed at the center of the front end cover 2. The center of the end cover 5 is equipped with a universal ball joint 6 for connecting other pipeline detection equipment, such as figure 2 As shown, the driving joint 3 includes a main frame 3-1, a driving mechanism 3-2 and a telescopic mechanism 3-3, and a plurality of driving mechanisms 3-2 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com