pipe robot

A pipeline robot and robot technology, applied in the direction of special pipes, pipe components, mechanical equipment, etc., can solve the problems of poor pipeline adaptability, low degree of freedom, inability to turn and walk in pipelines, etc., and achieve the effect of remote control and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

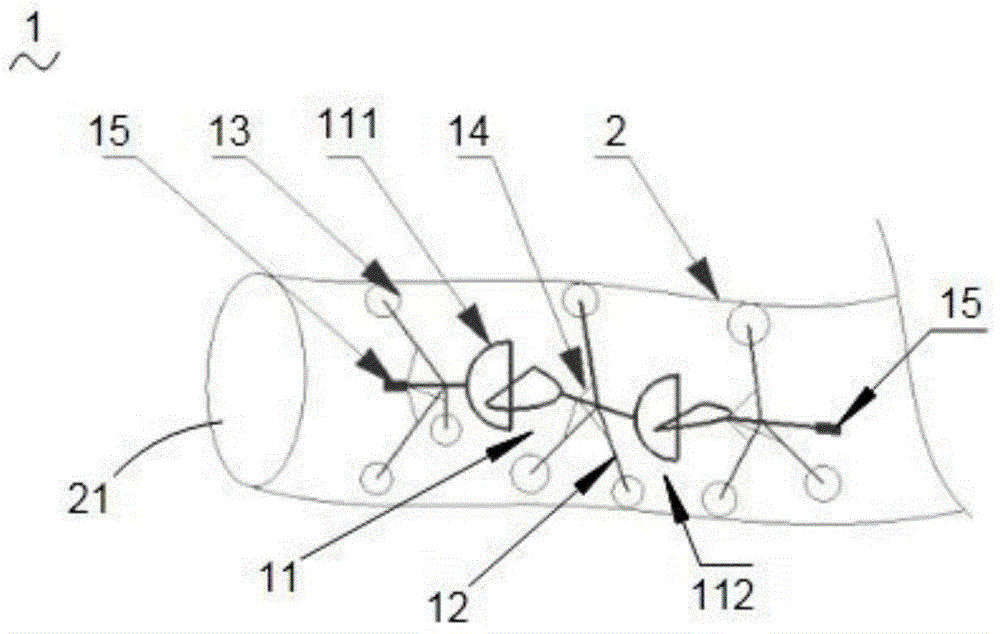

[0023] see figure 1 , figure 1 Shown is a structural schematic diagram of the pipeline robot of the present invention. The pipeline robot 1 includes: a robot skeleton 11, the robot skeleton 11 is further formed in series by the first cross-axis universal hinge 111 and the second cross-axis universal hinge 112; a strut 12, the support One end of the rod 12 is hingedly connected to the robot frame 11, the other end of the rod 12 is fixedly provided with the transmission wheel 13, and the end of the rod 12 connected to the robot frame 11 passes through the elastic element 14 to adjust the opening angle of the pole 12; the transmission wheel 13, the transmission wheel 13 is set at the end of the pole 12 different from the robot skeleton 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com