Copper wire outer wall drying treatment device

A technology of drying treatment and copper wire, applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., can solve the problems of copper wire oxidation, affecting the performance of copper wire, etc., to reduce the cost of use and ensure the performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

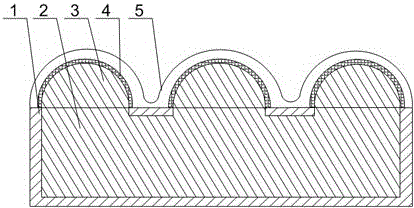

[0019] Such as figure 1 As shown, the present embodiment includes a box body 1, and a plurality of through holes are opened above the box body 1, and a sponge block 2 is filled in the box body 1, and the upper surface of the sponge block 2 passes through the through holes to The absorption part 3 is formed by protruding outward, and a plurality of sieve plates 4 for wrapping and covering the absorption part 3 are arranged on the box body 1 , and a dehumidifying cloth 5 is bonded on the upper surfaces of the plurality of sieve plates 4 . When in use, the box body 1 is filled with a sponge block 2, and the sponge block 2 protrudes outwards using a plurality of through holes on the upper part of the box body 1 to form an absorption part 3, which can be semicircular, rectangular, oval or other Regular geometry, while covering the sieve plate 4 wrapped on the absorption part 3 to match the shape of the absorption part 3, using the dehumidification cloth 5 bonded on the sieve plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com