Lithium battery incoming material detection line

A lithium battery and detection line technology, which is applied in the field of lithium battery incoming material detection line, can solve problems such as voltage capacity and internal resistance data deviation, time-consuming, and affect the quality consistency of lithium batteries, so as to improve performance life and The effect of using safety, ensuring quality and reliability, and realizing traceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

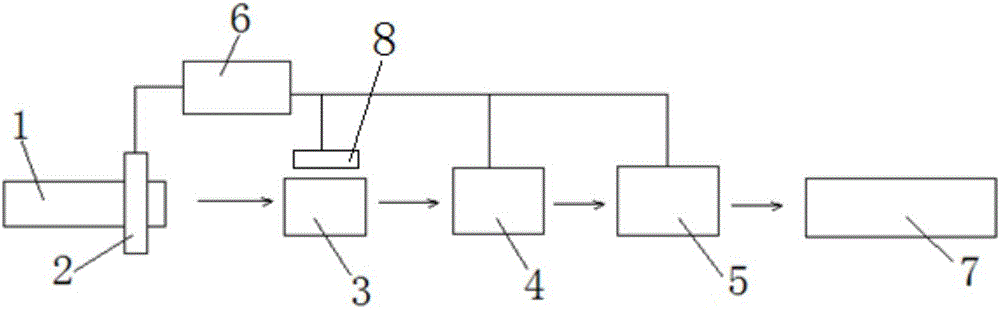

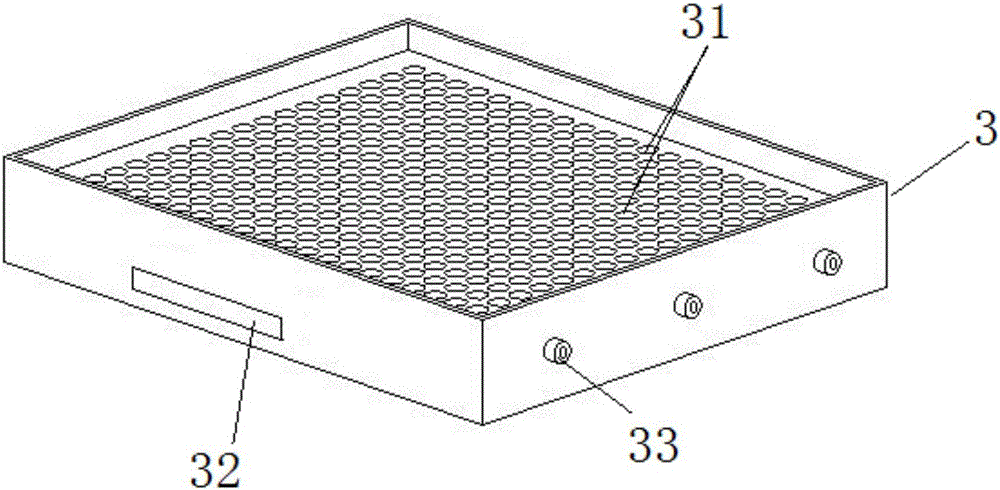

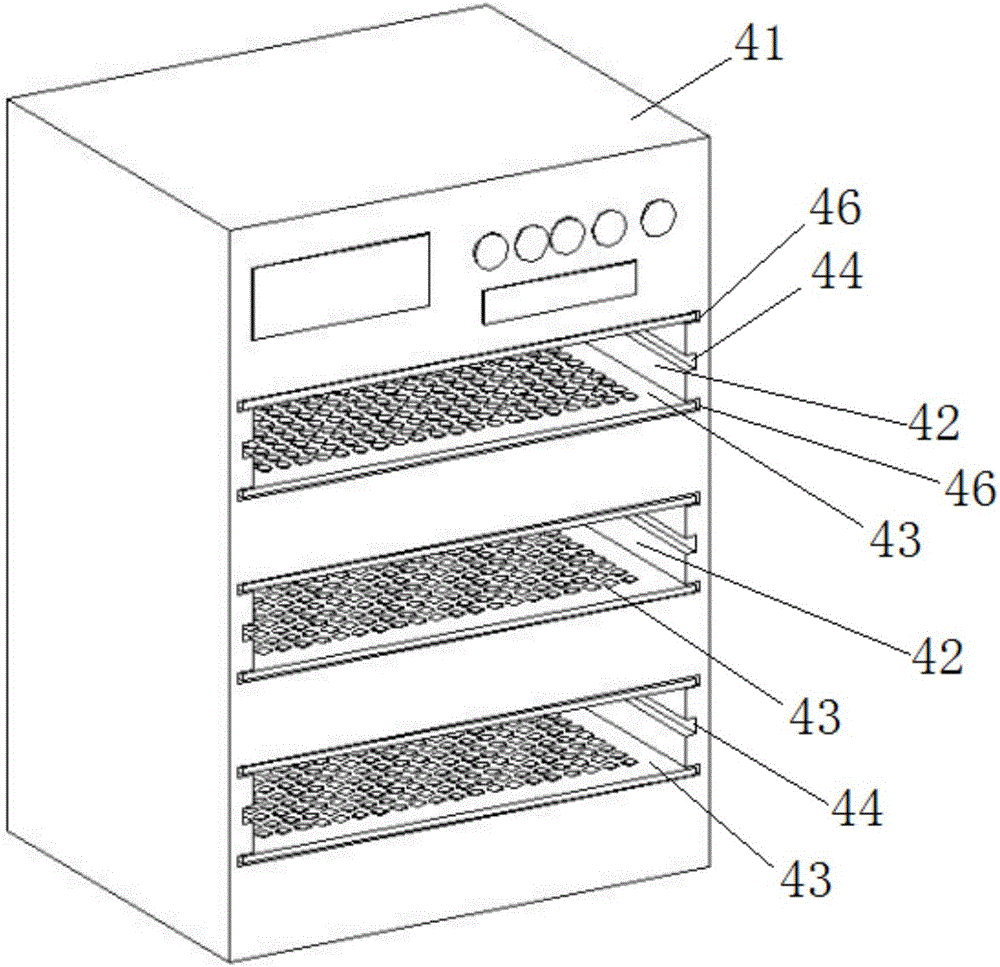

[0029] Such as figure 1 As shown, the lithium battery incoming detection line includes a conveying device 1 for conveying lithium batteries, a scanning device 2 installed above the conveying device 1 for scanning lithium battery barcodes, and an encoding tray 3 for placing lithium batteries scanned by the scanning device 2 ; Including a code scanner 8 for scanning the bar code of the encoding tray 3; including a formation device 4 for testing the voltage capacity and internal resistance of the lithium battery in the encoding tray 3; including testing and The screening device 5 for screening; also includes a control device 6 connected with the conveying device 1 , the scanning device 2 , the code scanner 8 , the chemical conversion device 4 and the screening device 5 .

[0030] Lithium batt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com