Method for extracting drum load spectrum of cutting unit of drum shearer

A technology of shearer cutting part and extraction method, which is applied in the direction of instrumentation, calculation, electrical digital data processing, etc., can solve the problems of safety problems, signal, interference, and high economic cost, and achieve the effect of approaching the real load and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

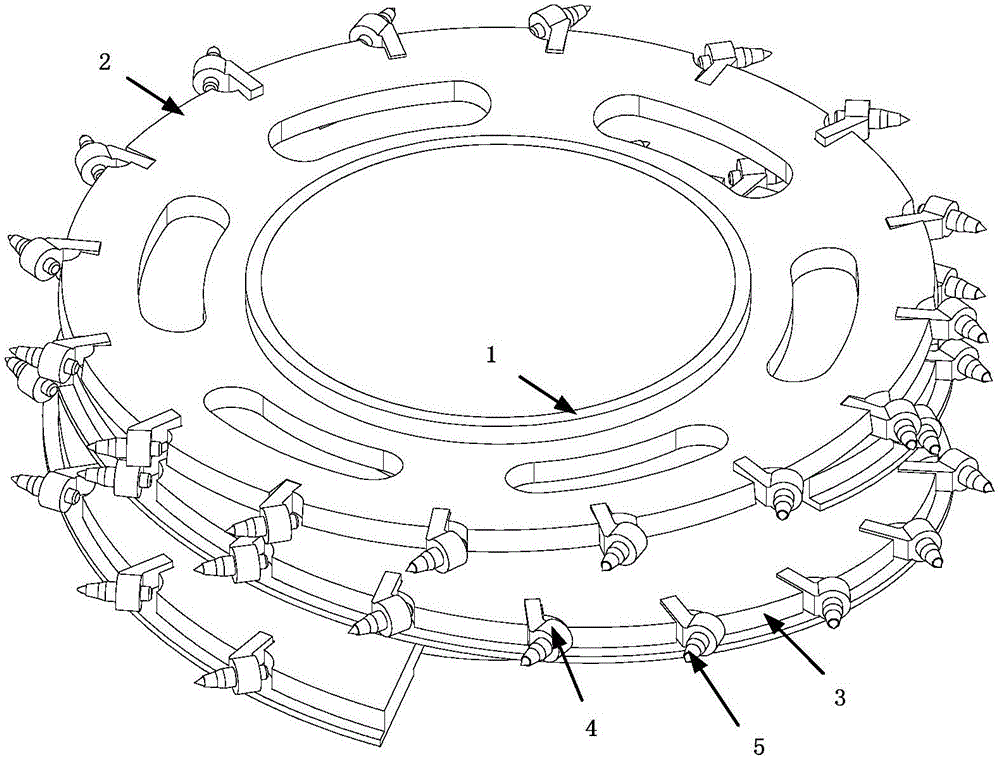

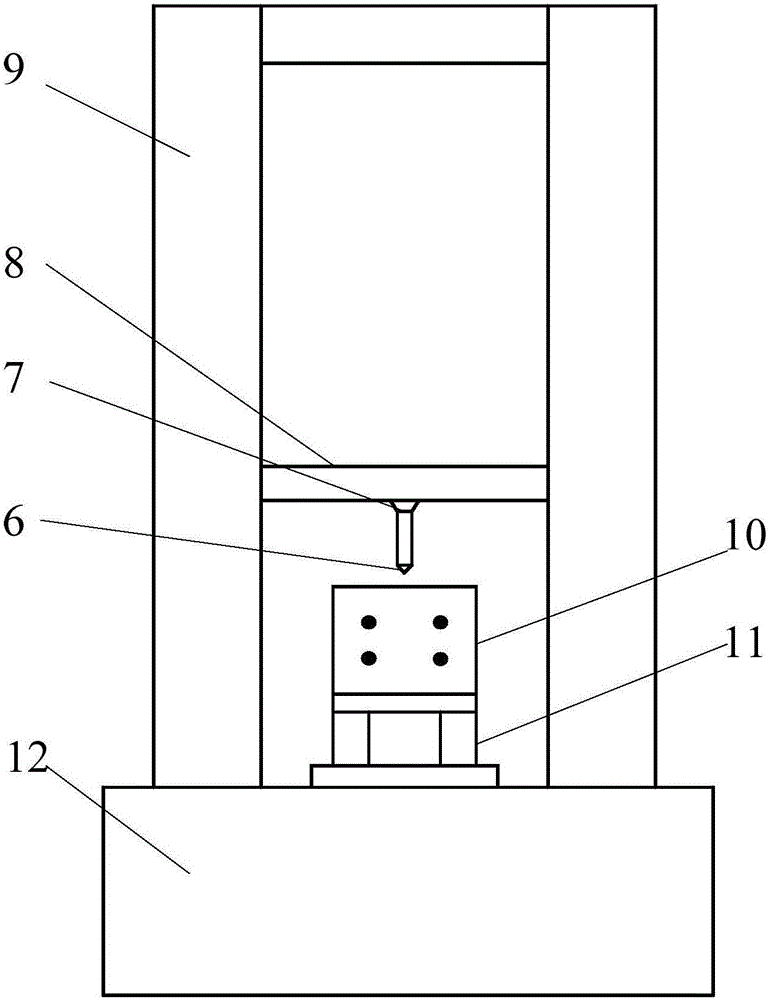

[0051] A method for extracting a drum load spectrum of a cutting part of a drum shearer, comprising:

[0052]Step 1. Acquire the coal rock occurrence conditions of the coal rock samples according to the actual coal rock working conditions; the coal rock occurrence conditions include the uniaxial instantaneous compressive strength of the coal seam, the average cutting impedance, the brittleness coefficient and the exposed free surface influence coefficient.

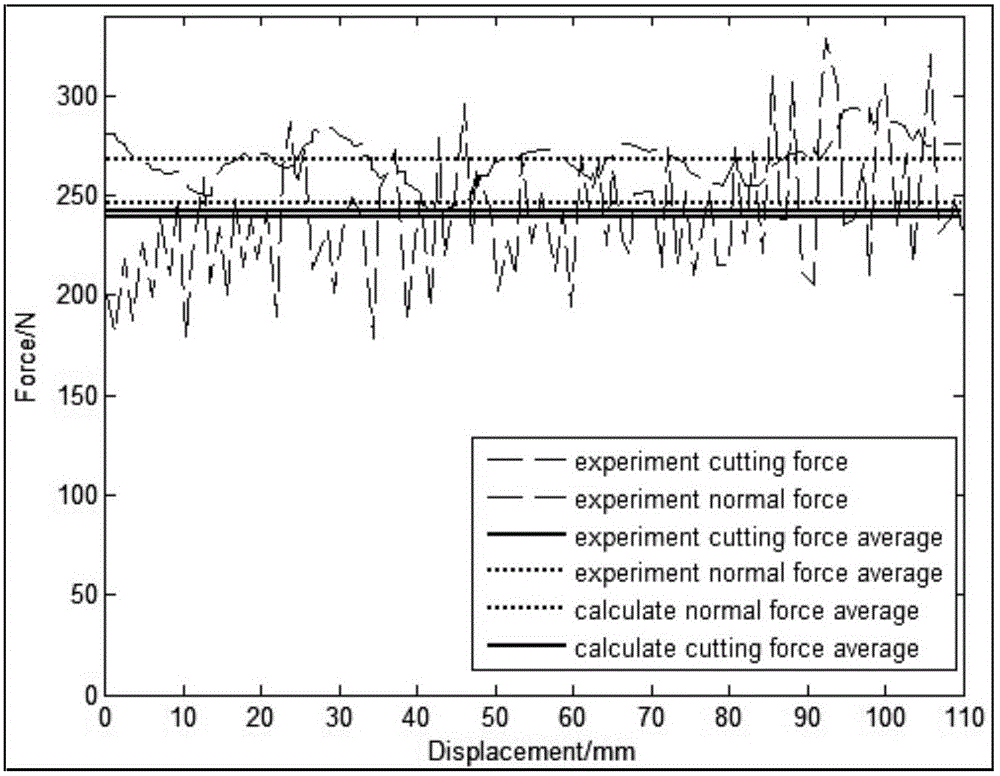

[0053] Step 2. Test the stress of a single pick on the drum of the cutting section of the coal machine to obtain the average load model of a single pick; the average load model of a single pick includes: the average cutting resistance when a single pick cuts coal and rock model, the average traction resistance model when a single pick cuts coal and rock, and the average late...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com