Testing device for sealing performance of hollow bolts and testing method

A technology of hollow bolts and testing devices, which is applied in fluid tightness testing, measuring devices, testing of machine/structural components, etc., can solve the problem of leakage of joint components, without consideration of the comprehensive influence of pulse, vibration, and temperature changes, and cannot be tested Evaluate the sealing performance of hollow bolts and other issues, to achieve the effect of real sealing performance test and obvious comparison effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

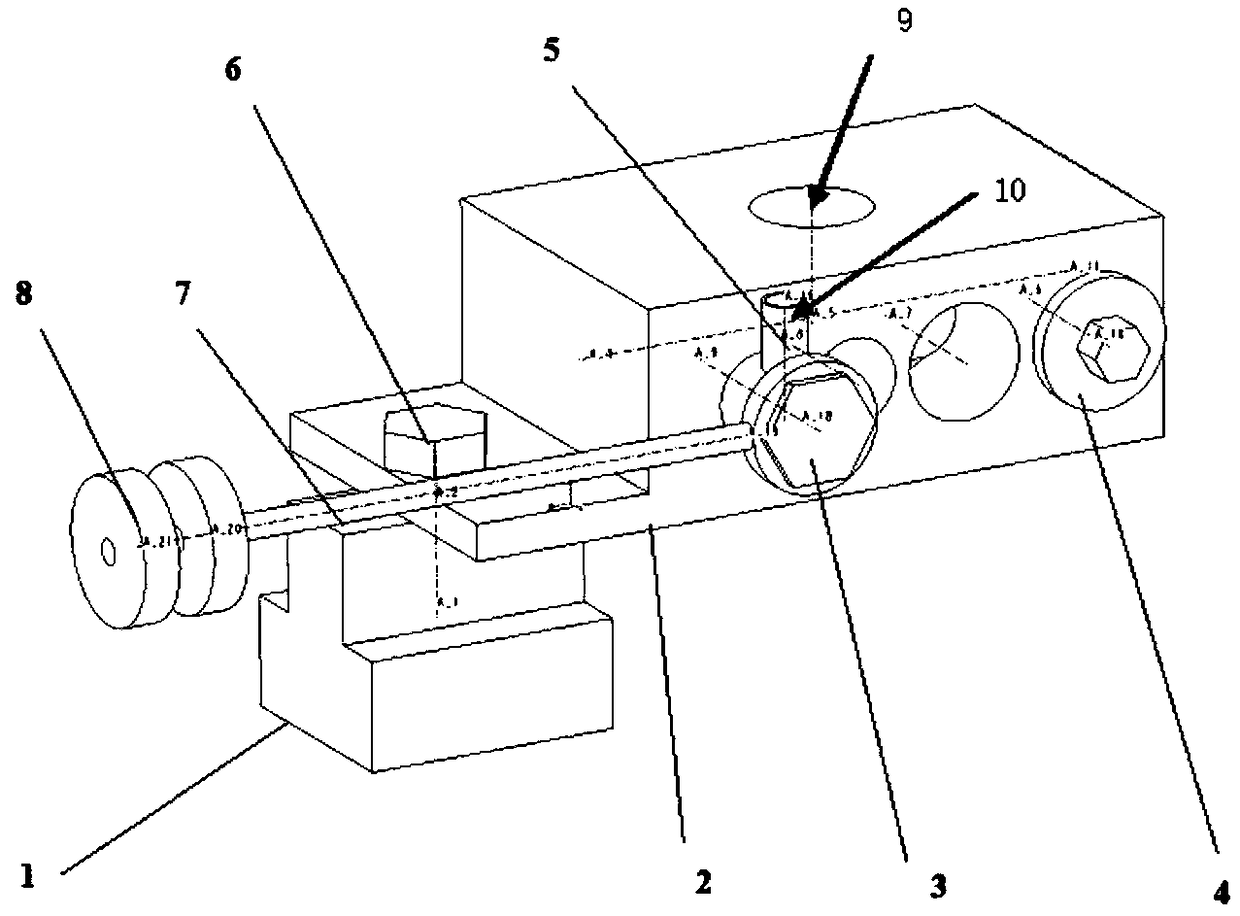

[0023] Example: Take the hollow bolt used in the transmission part of an armored vehicle as an example, install the joint assembly and tooling as required, and select 69 times for the test pulse frequency and waveform referring to HB6133-87 "Pulse Test of Hydraulic Hose, Conduit, and Joint Assembly" / min water hammer wave. The pulse peak pressure is set according to the actual working conditions of the hollow bolt. The average pulse pressure of this hollow bolt is 30MPa, and the peak pressure is 45MPa; The pressure selection is 42MPa (the maximum pulse of the hydraulic pulse type seal detection vibration test bench is 50MPa). The selection of vibration frequency and amplitude is consistent with the frequency and amplitude under the actual working condition of the hollow bolt assembly. The hollow bolt selects the working condition with a vibration frequency of 20Hz and an amplitude of 1mm; when the working condition is not clear, refer to GJB 150.16A-2009 "Military Equipment La...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com