Composite gas discharge tube

A composite gas and discharge tube technology, applied in solid cathode components and other directions, can solve the problems of inconvenient external circuits, unsuitable use, complex protection circuits, etc., and achieve the effects of convenient external circuits, reducing product size, and improving integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

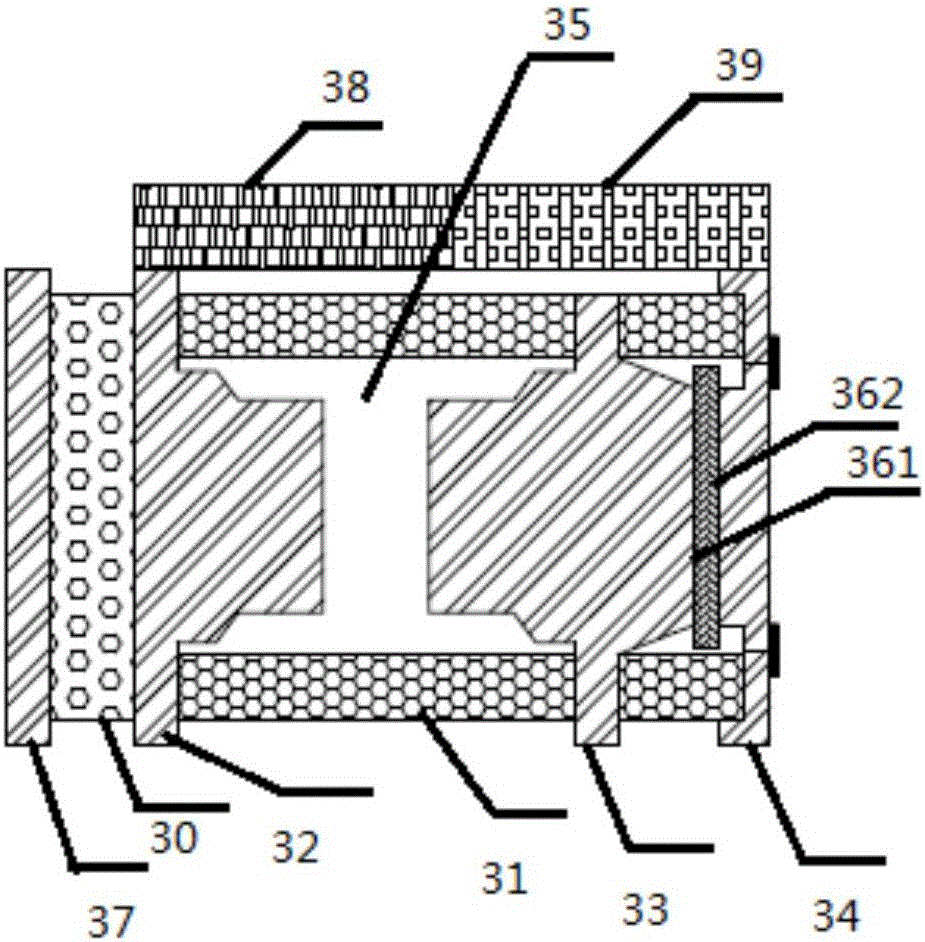

[0018] In the following, the present invention will be further described by using the following embodiments in conjunction with the accompanying drawings. It should be noted in advance that the insulating tube body referred to in the present invention is glass tube, porcelain tube or other insulating tube body suitable for composite gas discharge tube; the composite gas discharge tube referred to in the present invention includes triode and multi-electrode tube. For simplicity of description, a triode is used as an example for illustration.

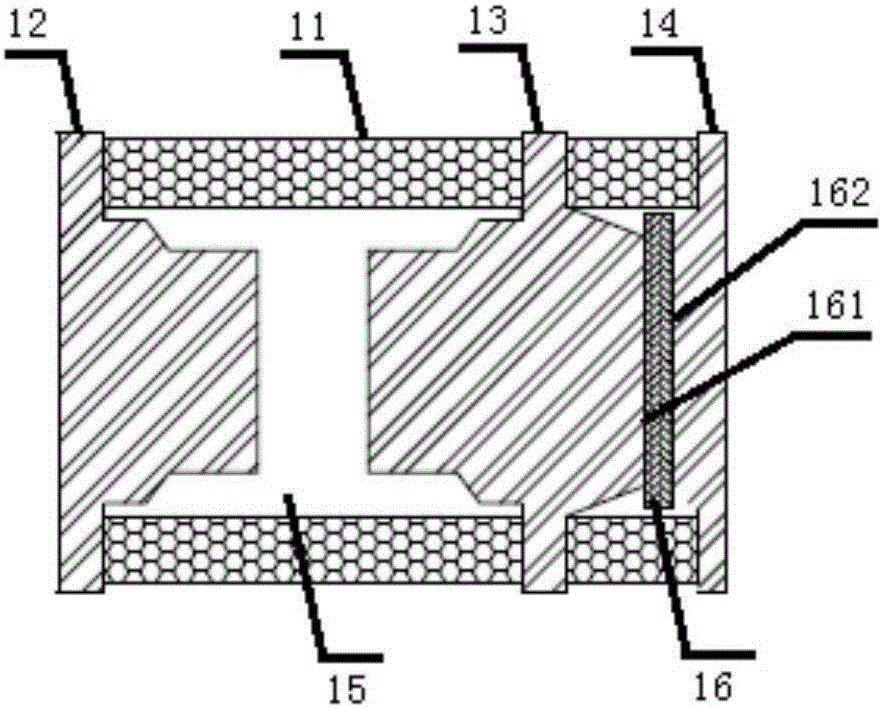

[0019] see figure 1 , figure 1 It is a schematic diagram of the appearance of the composite gas discharge tube provided in Embodiment 1 of the present invention. Such as figure 1 As shown, the composite gas discharge tube of this embodiment includes: an insulating tube body 11, a first electrode 12, an intermediate electrode 13 and a second electrode 14, and the first electrode 12, the intermediate electrode 13 are sealed and connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com