Biarc eagle nozzle dibbling compound device

A combined device and double-arc technology, which is applied to planter parts, plant protection covers, gardening, etc., can solve the problems of mulch film piercing, affecting the sowing efficiency and sowing quality, so as to reduce the resistance of entry into the soil, facilitate the cutting of mulch film, and prevent the The effect of dislocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

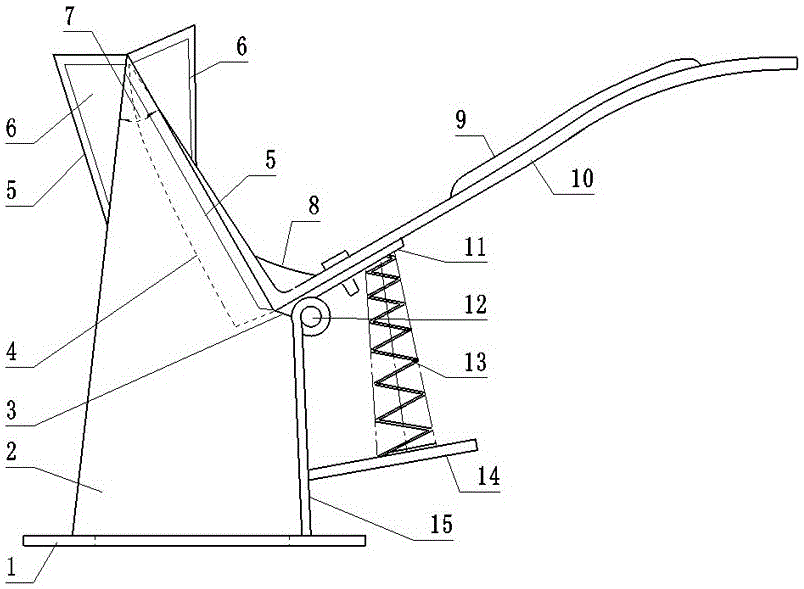

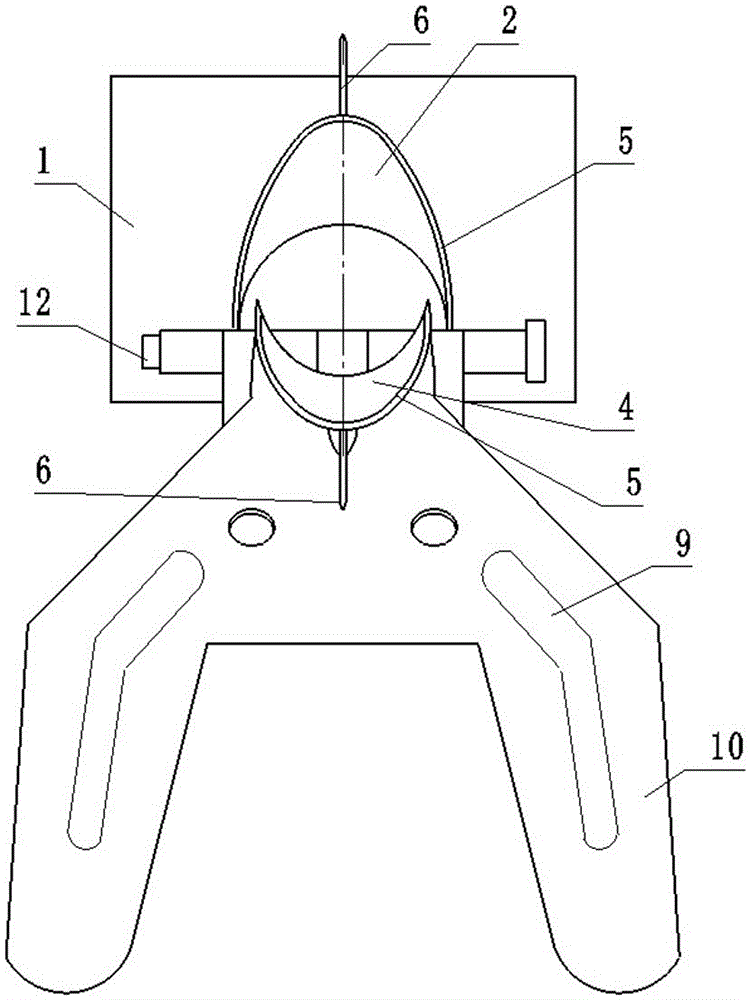

[0037] refer to Figure 1-Figure 4 , Figure 5 , a double-arc olecranon pointing combination device is characterized in that it mainly comprises: a moving olecranon 4, a fixed olecranon 2, and an olecranon opening and closing device;

[0038] Wherein the front end of the movable olecranon 4 is a groove-shaped end 21, and the front end of the fixed olecranon 2 is also a groove-shaped end 21. The movable olecranon 4 and the fixed olecranon 2 are hinged, and the movable olecranon 4 is hinged. The groove-shaped end 21 is wrapped in the arc-shaped groove-shaped end 21 of the fixed olecranon 2, and the movable olecranon 4 and the fixed olecranon 2 are fastened together to form a seed injection chamber;

[0039] The opening and closing device of the olecranon is installed between the movable olecranon 4 and the fixed olecranon 2, and is used for opening or fastening the movable olecranon and the fixed olecranon.

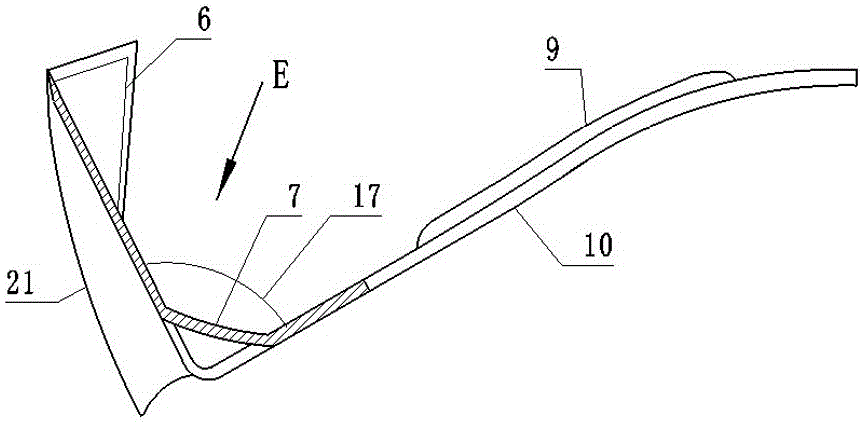

[0040] The sectional shape of the groove-shaped end 21 of the fixed ...

Embodiment 2

[0046] Compared with Embodiment 1, the difference of this embodiment is that the lower part of the fixed olecranon is connected with a positioning board 1 with a through hole.

Embodiment 3

[0048] Compared with Embodiment 2, the difference of this embodiment is that the back of the groove-shaped end 21 of the fixed olecranon 2 is provided with a membrane-breaking blade 6, and the membrane-breaking blade 6 is provided with a knife-shaped edge. The film blade 6 is vertically arranged on the outer arc surface of the back of the groove-shaped end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com