A Friction Stir Welding Method Between Dissimilar Metal Plates

A technology of friction stir and welding method, which is applied in welding equipment, metal processing, metal processing equipment, etc., and can solve the limitation of stress on dissimilar metal connectors of single-side lap joint structure, which cannot meet the requirements of welding quality and strength. and other issues, to achieve the effect of improving connection performance, improving forming, and reducing heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

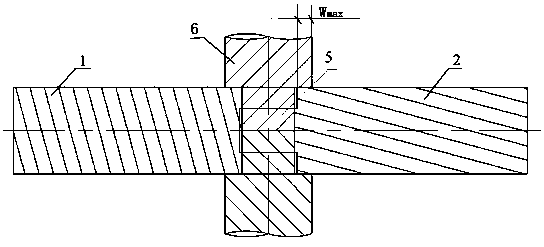

[0032] A friction stir welding method between dissimilar metal plates, comprising the following steps:

[0033] 1) Determine the relative thickness of the two metal plates to be welded:

[0034] In this example, 5052 aluminum alloy plate and 316L stainless steel plate are used for welding, because the melting point difference between the two is above 600°C, so it can be determined to use two metal plates with different thicknesses. In this example, 5052 aluminum plate with a thickness of 4.5mm is used. The alloy plate is welded with a 4mm thick 316L stainless steel plate (because the melting point of 5052 aluminum alloy is lower than that of 316L stainless steel).

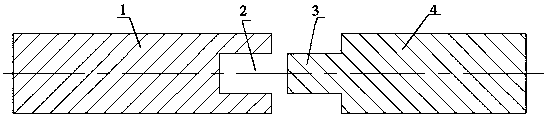

[0035] 2) Process the joint structure at the welding ends of the two metal plates to be welded:

[0036] In this embodiment, a rectangular groove is processed at the welding end of the 5052 aluminum alloy plate with a low melting point. The depth of the rectangular groove is 3 mm, the width of the rectangular groo...

Embodiment 2

[0045] A friction stir welding method between dissimilar metal plates, comprising the following steps:

[0046] 1) Determine the relative thickness of the two metal plates to be welded:

[0047] In this embodiment, TC4 titanium alloy plate and 316L stainless steel plate are selected for welding, because the melting point difference between the two is below 600°C, so it can be determined to use two metal plates with the same thickness. In this embodiment, TC4 titanium alloy with a thickness of 8 mm is used. Plate and 316L stainless steel plate are welded.

[0048] 2) Process the joint structure at the welding ends of the two metal plates to be welded:

[0049] In this embodiment, a rectangular groove is processed at the welding end of the TC4 titanium alloy plate with a low melting point. The depth of the rectangular groove is 5mm, and the width of the rectangular groove is 4mm. The opening direction of the rectangular groove is the same as that of the TC4 titanium alloy plate...

Embodiment 3

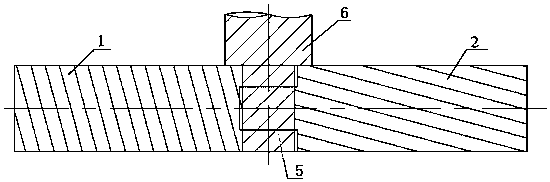

[0058] A friction stir welding method between dissimilar metal plates, comprising the following steps:

[0059] 1) Determine the relative thickness of the two metal plates to be welded:

[0060] In this example, 5052 aluminum alloy plate and TA2 pure titanium plate are selected for welding, because the melting point difference between the two is above 600°C (the melting point of 5052 aluminum alloy plate is low, and the melting point of TA2 pure titanium plate is high), so it can be determined to use For two kinds of metal plates with different thicknesses, in this embodiment, a 5052 aluminum alloy plate with a thickness of 10 mm is used for welding with a TA2 pure titanium plate with a thickness of 9 mm.

[0061] 2) Process the joint structure at the welding ends of the two metal plates to be welded:

[0062] In this embodiment, a rectangular groove is processed at the welding end of the 5052 aluminum alloy plate with a low melting point. The depth of the rectangular groove ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com