Bamboo-wood cutting machine

A cutting machine, bamboo and wood technology, applied in the direction of forming/shaping machine, wood processing equipment, special forming/shaping machine, etc., can solve the problems of inconvenient transportation or packaging, waste of energy, increase production cost, etc., and achieve production efficiency and variety improvement, production cost reduction and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention is described further:

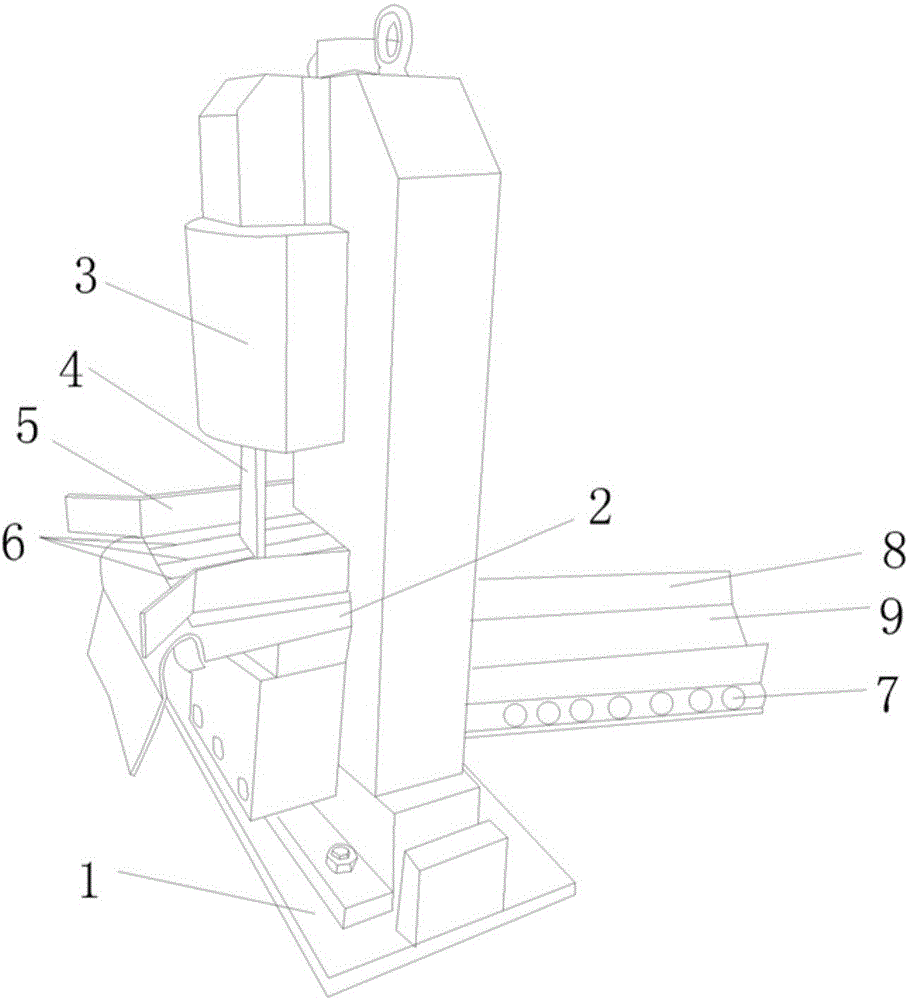

[0016] Such as figure 1 As shown, a high-efficiency bamboo and wood cutting machine is provided with a bamboo and wood placement platform 2 on the base 1. The bamboo and wood placement platform 2 is facing the conveying mechanism arranged on one side of the cutting machine, and a cutting mechanism 3 is arranged on the base. The cutting mechanism 3 It includes a cutting knife 4 that reciprocates up and down, and a plurality of partition bars 6 are arranged at intervals on the placement platform, and the partition bars 6 divide the placement platform into multiple conveying tracks. The left and right positions of the divider are adjustable. The rear end of the divider is connected to the seat body of the cutting mechanism through fasteners, or the divider is bonded to the placement platform. Correction mechanisms are set on both sides of the feeding port where the platform is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com