MMA washing tower acidity removing method and device applied to same

A washing tower and acidity technology, applied in chemical instruments and methods, separation/purification of carboxylate, preparation of carboxylate, etc., can solve the problems of increased material loss, increased operating costs, long time, etc., to reduce material The probability of aggregation, increasing the operating cycle of the device, and solving the effect of short operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

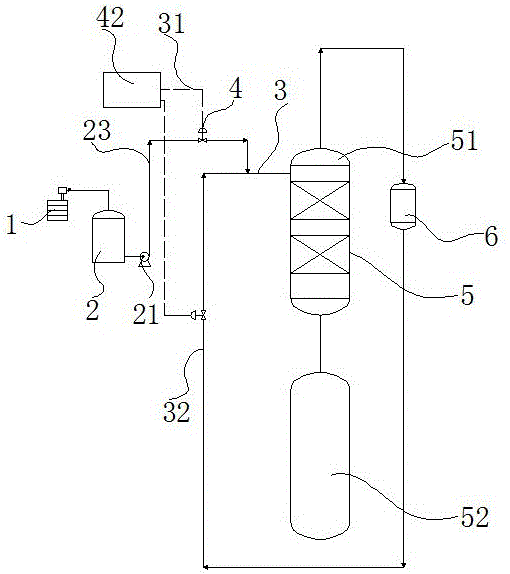

Image

Examples

Embodiment 1

[0029] Embodiment 1, a kind of MMA washing tower acidity elimination method comprises the steps:

[0030] 1) Configure ethylenediamine solution with a concentration of 9%-12% through the liquid inlet device;

[0031] 2) Transport the above-mentioned ethylenediamine solution to the reflux liquid at the top of the MMA washing tower, and control the flow rate of the ethylenediamine solution to be 0.4%-0.6% of the reflux liquid at the top of the MMA washing tower, so that the ethylenediamine and the reflux liquid The MAA in the medium undergoes a neutralization reaction, and the reaction conditions of the neutralization reaction are pressure 1.0KPaA-5.0KPaA, temperature 75-88°C, and the reaction time is rapid reaction; the reaction conditions of the neutralization reaction are preferably pressure 4KPaA, temperature 80°C;

[0032] 3) Return the neutralization reaction product in step 2) to the esterification reactor, and reduce MAA from the neutralization reaction product by sulfur...

Embodiment 2

[0033] Example 2, in the method for eliminating the acidity of the MMA washing tower described in Example 1: the concentration of the ethylenediamine solution in the step 1) is 10%.

Embodiment 3

[0034] Example 3, in the method for eliminating the acidity of the MMA washing tower described in Example 1: the concentration of the ethylenediamine solution in the step 1) is 9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com