An aluminum alloy profile with good electrical conductivity and its processing method

A technology for aluminum alloy profiles and electrical conductivity, applied in the field of aluminum alloy profiles, can solve problems such as insufficient electrical conductivity, insufficient alloy grain uniformity and fineness, and achieve good mechanical properties, good air tightness, and easy production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

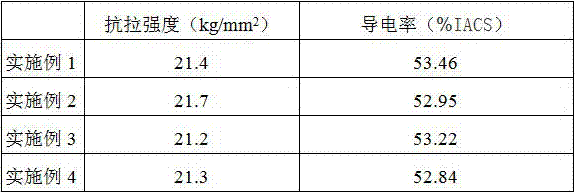

Examples

Embodiment 1

[0029] The first aluminum alloy profile with good electrical conductivity, the aluminum alloy profile includes components with the following mass content:

[0030] Mg 3%

[0031] Si 2%

[0032] Ni 0.2%

[0033] Sr 1%

[0034] La 0.47%

[0035] The balance is Al.

[0036] The processing method of the aluminum alloy profile with good electrical conductivity is carried out as follows:

[0037] 1) Weigh the material according to the following weight ratio,

[0038] Mg 3%

[0039] Si 2%

[0040] Ni 0.2%

[0041] Sr 1%

[0042] La 0.47%

[0043] The balance is Al;

[0044] Among them, Ni and La are converted into LaNiO 3 The weight of LaNiO 3 It is added to the composition as a raw material for smelting, so the molar ratio of Ni and La is 1:1; during metal processing, Al and Ni can form a Raney nickel alloy, which is chemically unstable. When the nickel content When it is high, it can spontaneously ignite in the air and has certain dangers. Through LaNiO 3 Ni and La a...

Embodiment 2

[0051] The second kind of aluminum alloy profile with good electrical conductivity, the aluminum alloy profile includes the following components by mass content:

[0052] Mg 5%

[0053] Si 3.5%

[0054] Ni 0.8%

[0055] Sr 1.5%

[0056] La 1.88%

[0057] The balance is Al.

[0058] The processing method of the aluminum alloy profile with good electrical conductivity is carried out as follows:

[0059] 1) Weigh the material according to the following weight ratio,

[0060] Mg 5%

[0061] Si 3.5%

[0062] Ni 0.8%

[0063] Sr 1.5%

[0064] La 1.88%

[0065] The balance is Al;

[0066] Among them, Ni and La are converted into LaNiO 3 The weight of LaNiO 3 It is added to the composition as a raw material for smelting, so the molar ratio of Ni and La is 1:1;

[0067] 2) Vacuum melting the above composition at 750°C;

[0068] 3) The smelted alloy material is subjected to solution treatment at 550°C for 3 hours; 4) The alloy material after solution treatment is processe...

Embodiment 3

[0072] The third kind of aluminum alloy profile with good electrical conductivity, the aluminum alloy profile includes components with the following mass content:

[0073] Mg 4%

[0074] Si 3%

[0075] Ni 0.6%

[0076] Sr 1.2%

[0077] La 1.41%

[0078]The balance is Al.

[0079] The processing method of the aluminum alloy profile with good electrical conductivity is carried out as follows:

[0080] 1) Weigh the material according to the following weight ratio,

[0081] Mg 4%

[0082] Si 3%

[0083] Ni 0.6%

[0084] Sr 1.2%

[0085] La 1.41%

[0086] The balance is Al;

[0087] Wherein, Ni and La are converted into LaNiO3 by weight, with LaNiO3 as raw material added to the composition for smelting;

[0088] 2) The above composition is vacuum smelted at 720°C; the smelting process is a process in which various materials are fused with each other, and it is also a purification process. The hydrogen originally stored in the aluminum can be precipitated and discharged,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com