Concentrating light-guiding concrete structural unit and construction method for light-transmitting wall

A technology of concrete structure and construction method, which is applied in the direction of walls, building components, building structures, etc., can solve the problems of high cost of light-guiding concrete, limited light-transmitting effect of light-guiding structures, etc., and improve light transmittance and light energy utilization efficiency, save transparent materials, increase the effect of spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

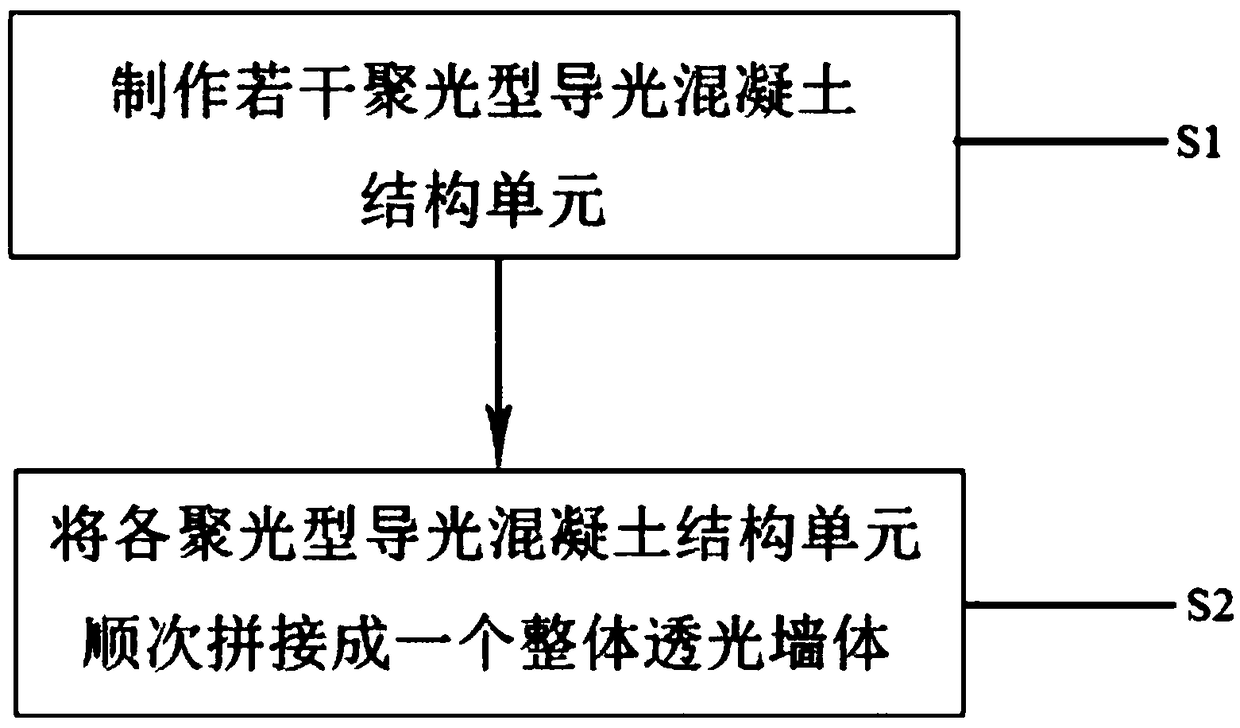

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

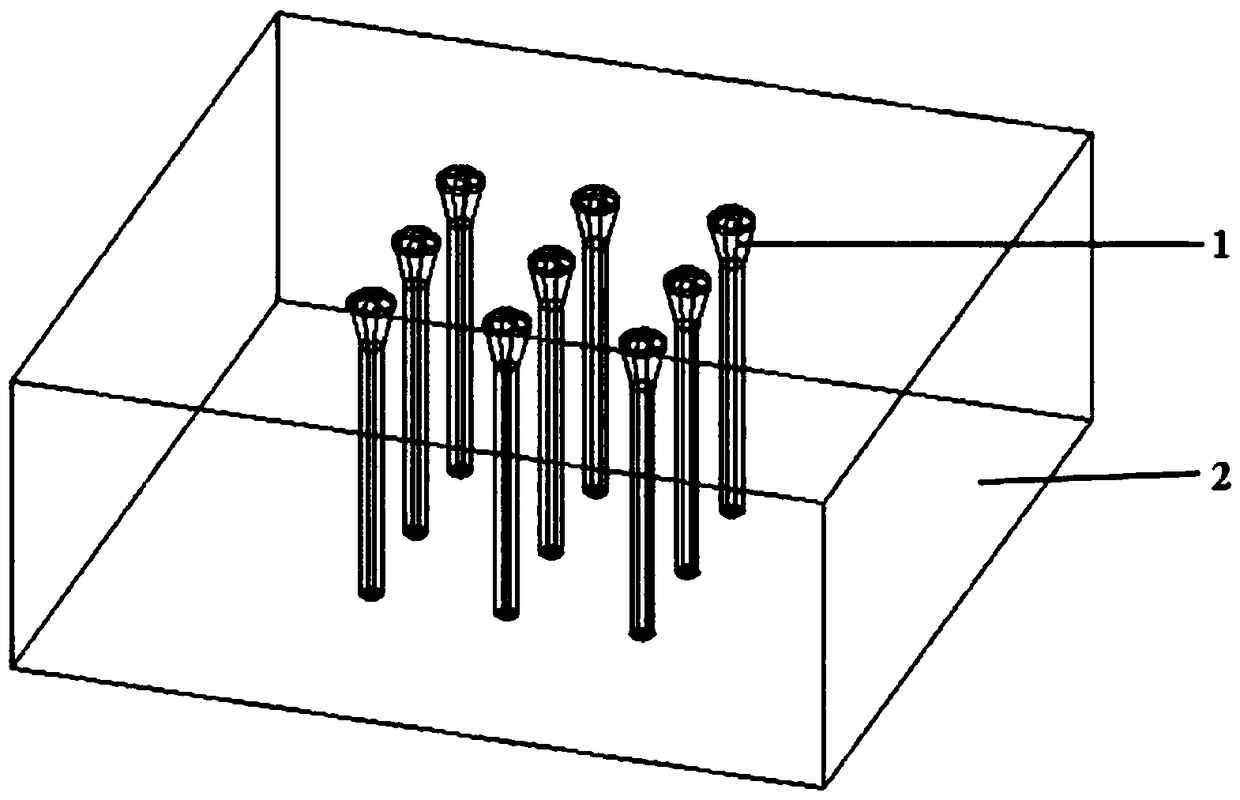

[0039] Figure 1 to Figure 2 An embodiment of a concentrating light-guiding concrete of the present invention is shown, which is mainly composed of several concentrating light-guiding tubes 1 interspersed in a self-compacting concrete matrix 2 .

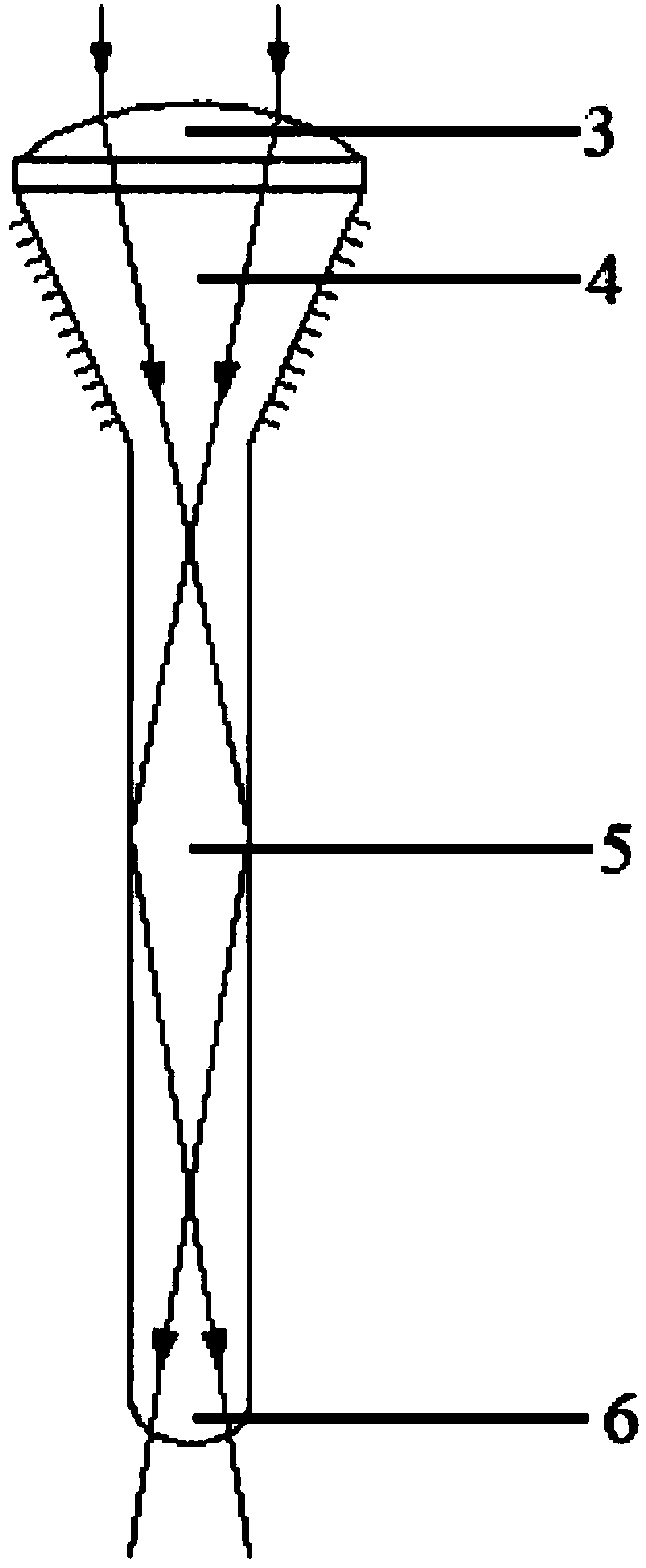

[0040] In this embodiment, the concentrating light guide tube 1 is integrally made of transparent material, and its position is fixed by the side panel 8 and the limit steel sheet 10 in the supporting mold. Its side is coated with reflective film or materials with lower refractive index to enhance the reflectivity and reduce the loss of absorption and scattering.

[0041] In this embodiment, the concentrating light guide tube 1 is composed of a light input end, an intermediate light guide tube 5 and a light output end 6 . The light input end is a light-condensing prism, and the light outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com