A Reinforcement Method for Narrow Coal Pillars in Gob-side Driving

A technology for narrow coal pillars and coal walls is applied in the field of reinforcement of narrow coal pillars in gob-side tunnels, which can solve the problems of low recovery rate of coal resources, small central elastic core area, serious roadway fragmentation, etc., so as to reduce roadway repairs. The effect of increasing the elastic core area, resisting the shear failure and compressive failure of the surrounding rock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

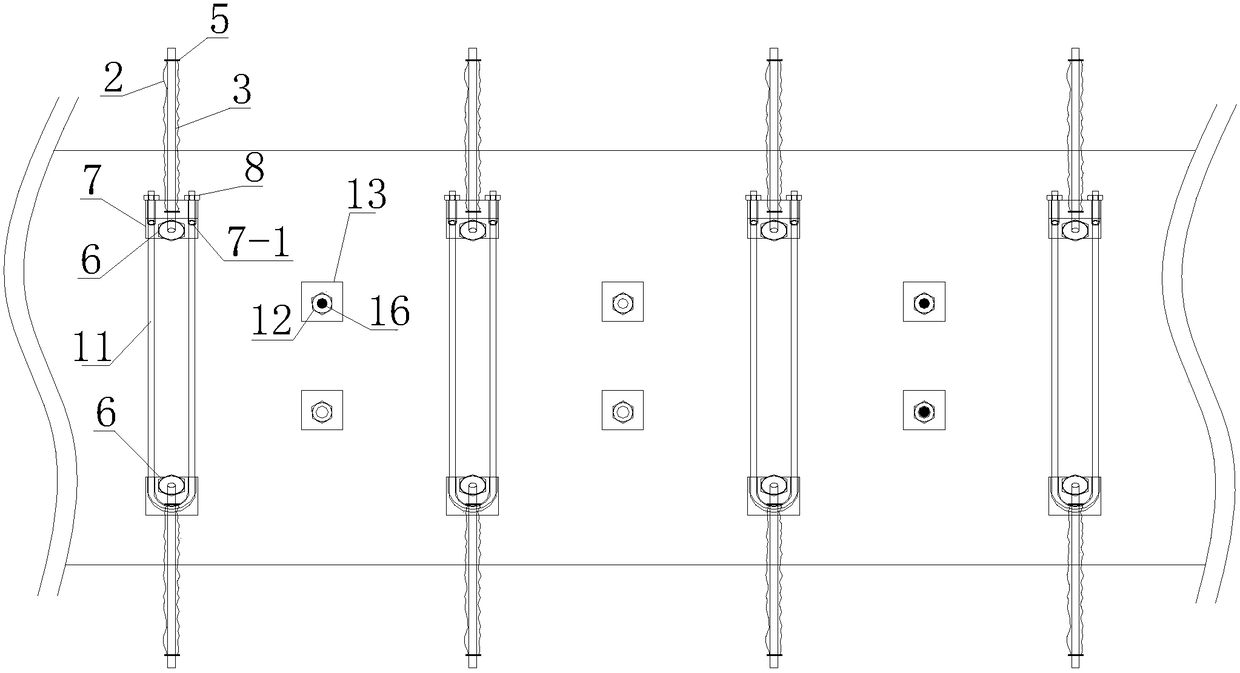

[0039] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

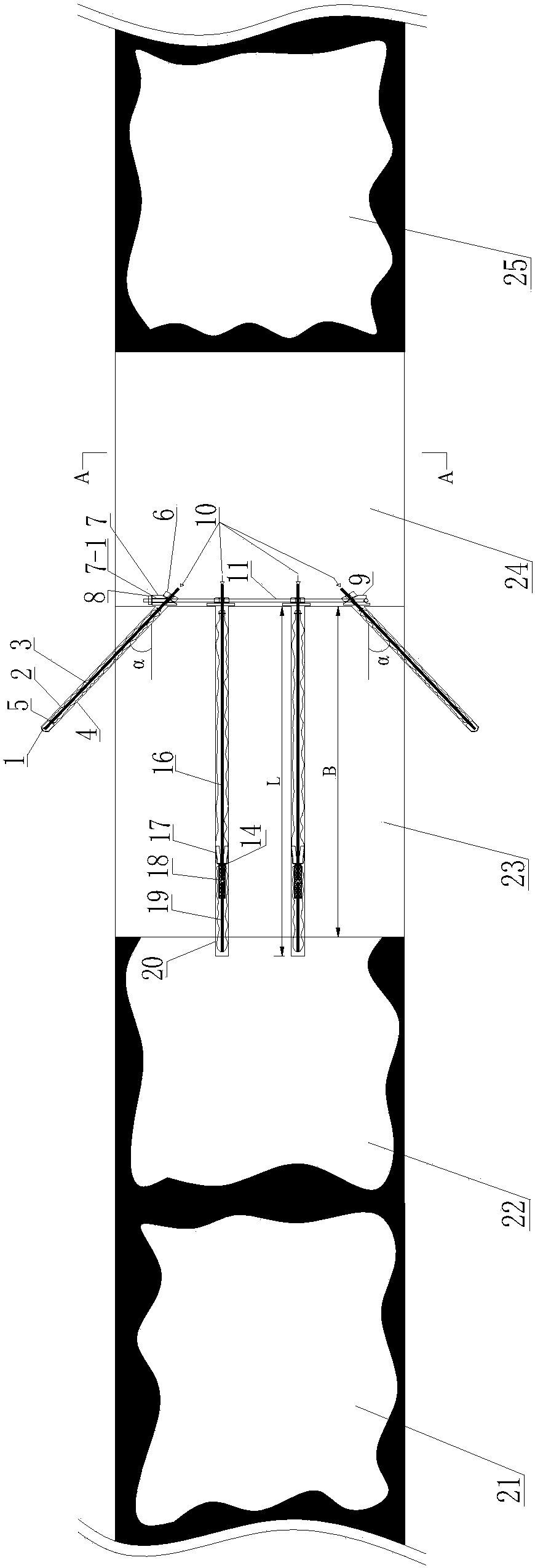

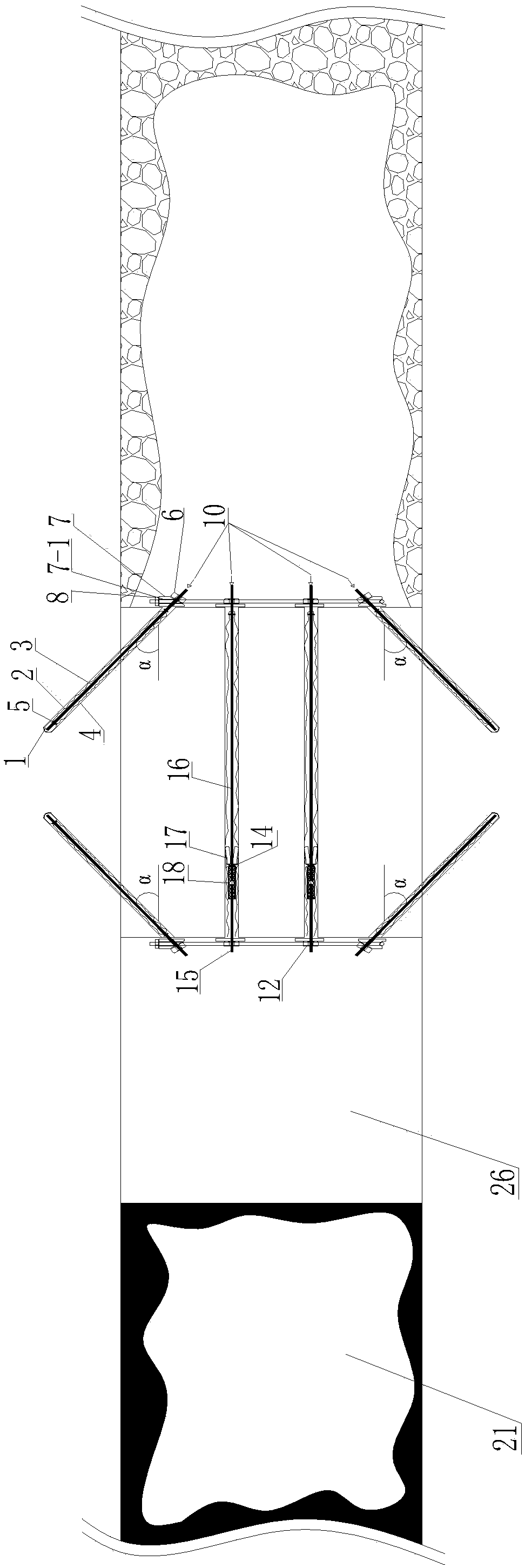

[0040] As shown in the figure, one side of the narrow coal pillar 23 is provided with an upper section mining roadway 24, the other side of the upper section mining roadway 24 is the upper section to be mined working face 25, and the other side of the narrow coal pillar 23 is the lower section Roadway 22 to be excavated, the other side of the roadway 22 to be excavated in the lower section is the working face 26 to be mined in the lower section, and the method for reinforcing narrow coal pillars along the goaf roadway of the present invention comprises the following steps:

[0041] Step 1. Firstly, in the recovery roadway 24 in the upper section (at this time, the roadway 22 to be excavated in the lower section is solid coal), use a tunnel drilling rig or a bolter rig to drill into the narrow coal pillar 23 (set coal pillar width B=4.0m) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com