A goaf sealing method for preventing coal seam spontaneous combustion

A goaf and coal seam technology, applied in mining equipment, mining equipment, earthwork drilling, etc., can solve problems such as explosion safety accidents, cross-wind oxygen supply, gas combustion, etc. The effect of changing performance and improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

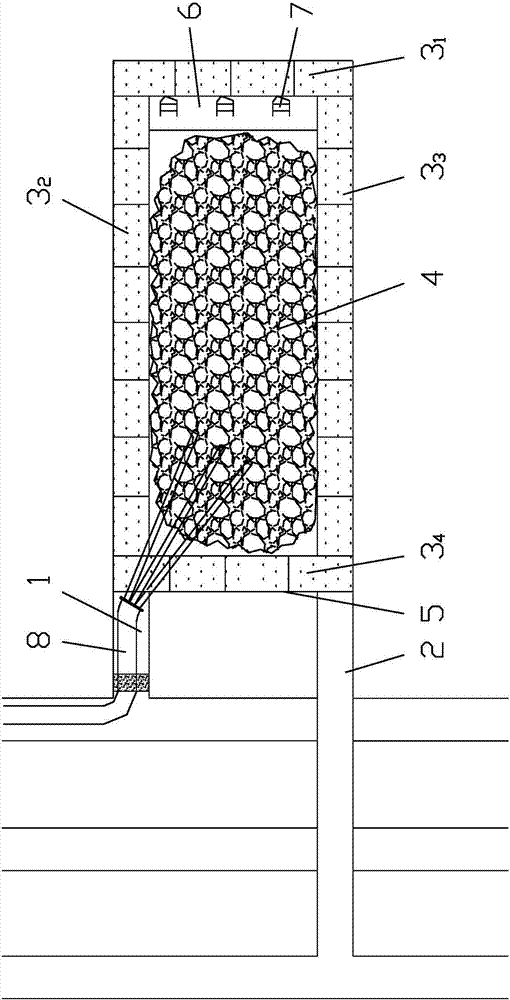

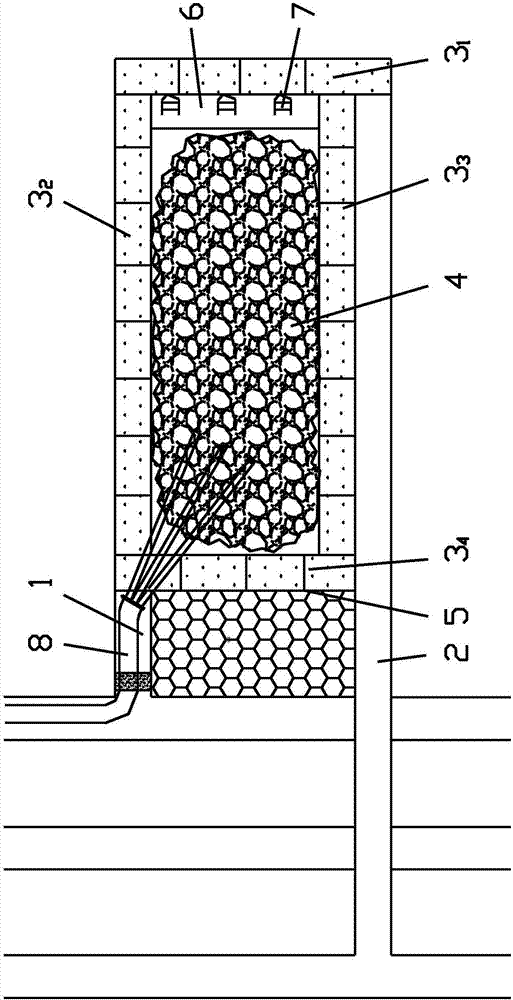

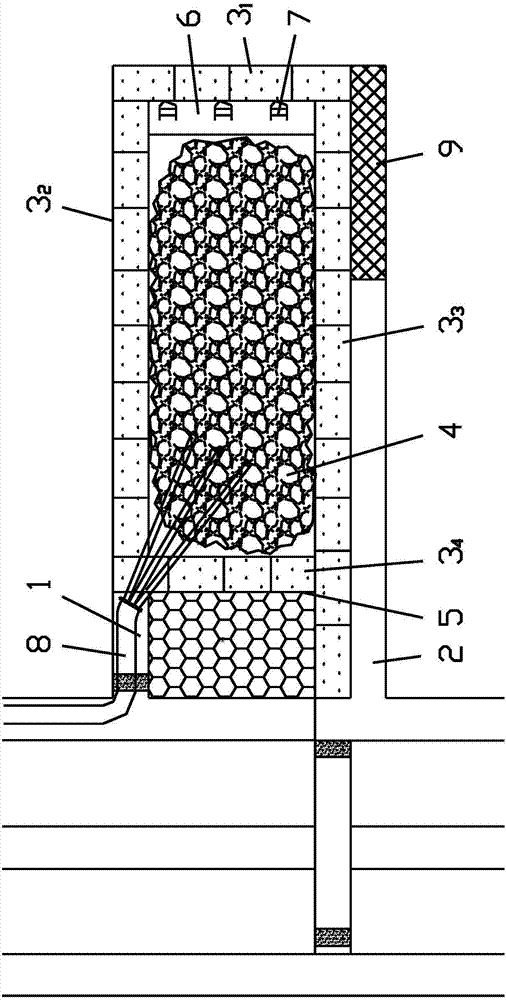

[0011] Such as figure 1 As shown, the present invention comprises the following steps: 1), after the mining face is pushed forward 3-5m from the cutting hole 6, when the top plate has not yet collapsed, the rear part of the hydraulic support 7 of the working face is sequentially returned to the wind from the transport chute 2 Along the channel 1, the support formwork of the super-high water material filling body is erected in sections, and a rectangular space is formed with the reserved coal wall. The sealed filling bag is hung in the space, and then the super-high water material slurry is filled into the filling bag. After the ultra-high water material slurry is solidified, the inner side sealing wall 3 of the goaf 4 is formed 1 ; 2), when the working face is pushed forward every 4-6m, adopt the method of opening 6 places of the cutout in step 1) respectively in the return air chute 1 and the transport chute 2, and make the upper and lower sides of the goaf 4 Sealed Wall 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com