Gypsum-based wall leveling material as well as preparation method and use method thereof

A gypsum-based and wall technology, applied in the field of building decoration materials, can solve the problems of high price of redispersible rubber powder and water repellent, increased material cost, difficult promotion, etc. Low, easier to apply promotion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] A kind of preparation method of gypsum base wall leveling material of the present invention, comprises the following steps:

[0063] Mix hemihydrate gypsum, fly ash, admixture, calcium hydroxide, zeolite, water retaining agent and retarder, and stir evenly;

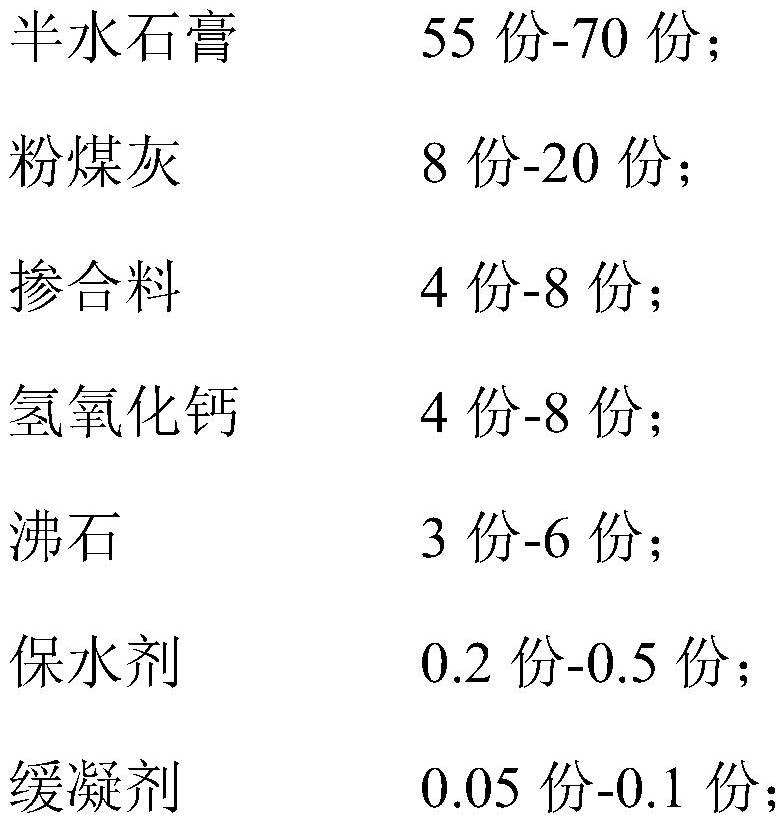

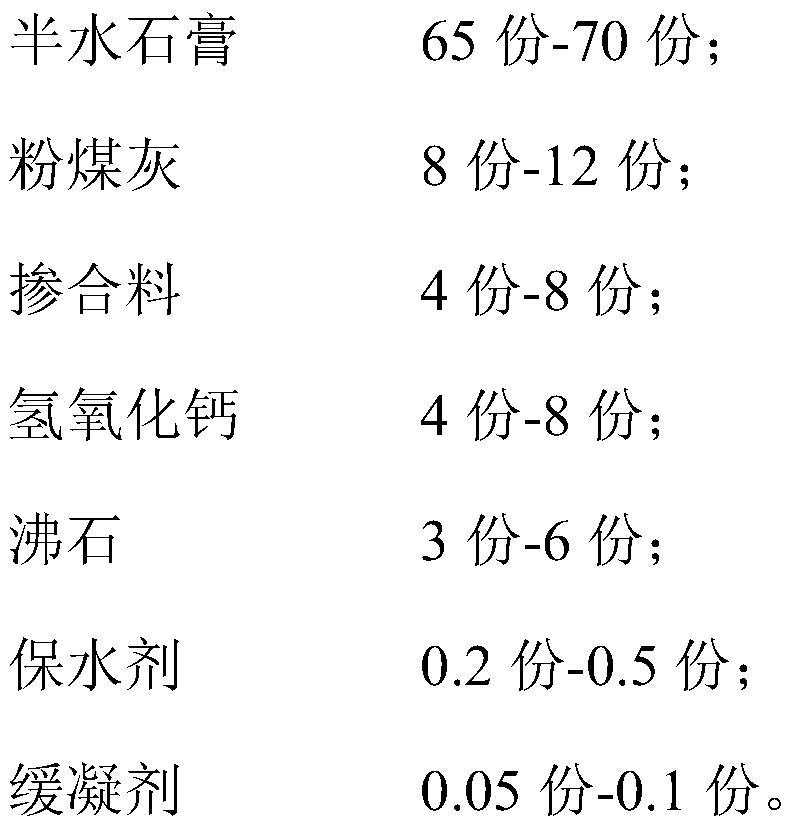

[0064] The mass portion of the hemihydrate gypsum is 55-70 parts; the mass portion of the fly ash is 8-20 parts; the mass portion of the admixture is 4-8 parts; the calcium hydroxide The mass parts of the zeolite are 4-8 parts; the mass parts of the zeolite are 3-6 parts; the mass parts of the water-retaining agent are 0.2-0.5 parts; the mass parts of the retarder are 0.05- 0.1 copies;

[0065] The admixture is selected from one or both of silica fume and metakaolin.

[0066] It can be understood that the raw materials can be mixed in a dry powder mixer, and the formula raw materials are added to the dry powder mixer in sequence, and stirred evenly to obtain a gypsum-based wall leveling material.

[0067] Prefer...

Embodiment 1

[0081] This embodiment provides a gypsum-based wall leveling material and its preparation method and use method, the steps are as follows:

[0082]Mix 650kg of α hemihydrate gypsum, 16.2kg of stone powder, 100kg of fly ash, 50kg of silica fume, 50kg of calcium hydroxide, 50kg of zeolite, 3kg of water retaining agent and 0.8kg of retarder, add 80kg of vitrified microbeads, and continue mixing for 3 minutes. Get gypsum-based wall leveling material.

[0083] According to the weight ratio [gypsum-based wall leveling material: water = 1:0.4], add water to the gypsum-based wall leveling material, stir evenly, and obtain product 1.

Embodiment 2

[0085] This embodiment provides a gypsum-based wall leveling material and its preparation method and use method, the steps are as follows:

[0086] Mix 700kg of α hemihydrate gypsum, 6.15kg of stone powder, 80kg of fly ash, 40kg of silica fume, 40kg of calcium hydroxide, 50kg of zeolite, 3kg of water retaining agent and 0.85kg of retarder, add 80kg of vitrified microbeads, and continue mixing for 3 minutes. Get gypsum-based wall leveling material.

[0087] According to the weight ratio [gypsum-based wall leveling material: water = 1:0.4], add water to the gypsum-based wall leveling material, stir evenly, and obtain product 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com