Shield electric pump

A technology of shielded electric pumps and shielded motors, applied to pumps, pump devices, pump components, etc., can solve the problems of wasting pipeline materials, inconvenient installation, energy waste, etc., to avoid waste, occupy less space, and improve transmission efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

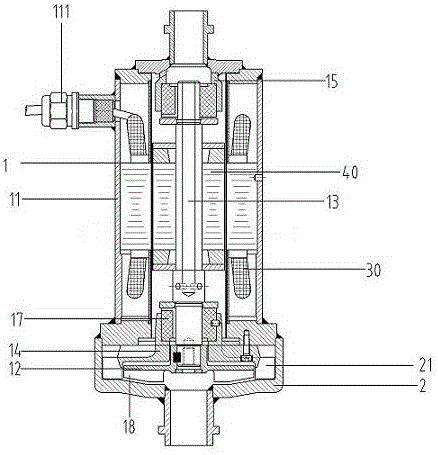

[0017] Such as figure 1 A canned electric pump shown includes a canned motor 1 and a pump body 2, and the pump body 2 is fixedly connected to the canned motor 1;

[0018] The pump body 2 is provided with a pump chamber 21;

[0019] The shielded motor 1 includes a motor casing 11, an impeller 12 and a rotating shaft 13, a front bearing seat 14 and a rear bearing seat 15 are arranged in the motor casing 11, and bearings are respectively arranged in the front bearing seat 14 and the rear bearing seat 15. 17. Both ends of the rotating shaft 13 are respectively connected with the bearings 17 in the front bearing housing 14 and the rear bearing housing 15, the impeller 12 is located in the pump cavity 21 and is fixedly connected with the rotating shaft 13, the impeller Guide vanes 18 are arranged on the outer side of 12, and the guide vanes 18 are connected to the rotating shaft 13. The motor housing 11 is provided with a stator assembly 30 and a rotor assembly 40 in sequence from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com