Heat-insulated composite refractory brick

A technology of refractory bricks and silicon molybdenum bricks, which is applied in the field of refractory bricks, can solve the problems of not achieving the effect of heat insulation layer, shortening the service life of products, and being easy to fall off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

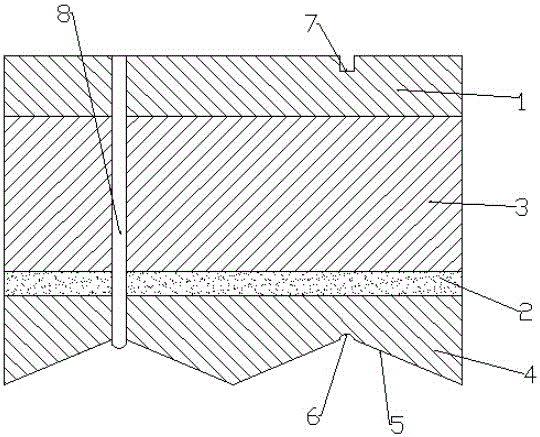

[0009] The specific technical solutions of the present invention are described in conjunction with the accompanying drawings.

[0010] Such as figure 1 As shown, the heat-insulating composite refractory brick includes a silica brick layer 1 on the top layer, a filling block 3 in the middle and a phosphate brick layer 4 on the lower layer. The lower surface 5 of the phosphate brick layer 4 is a concave-convex surface. There is also a groove 6 in the recess, corresponding to the upper silica molybdenum layer 1, there is a draw-in groove 7, and a jumper 8 is also included, and the two ends of the jumper 8 are respectively embedded in the groove 6 and the draw-in groove 7.

[0011] There are aluminum silicate fibers 2 between the filling block 3 and the phosphate brick layer 4 .

[0012] The silica brick layer 1, the middle filler block 3 and the phosphate brick layer 4 of the lower floor are fixed together by the clip spring 8, which is not easy to come off. The lower surface 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com