Test and prediction method for service life of bearing of axle box of train

A technology of axle box bearings and prediction methods, which is applied in the direction of mechanical bearing testing, special data processing applications, instruments, etc., can solve the problems of inaccurate prediction of high-speed rail bearing life, waste of high-quality resources, and increased maintenance costs, etc., to achieve good engineering practicality value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

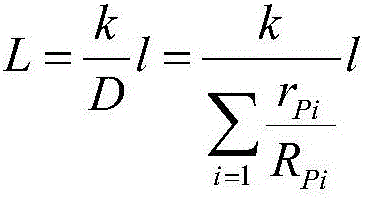

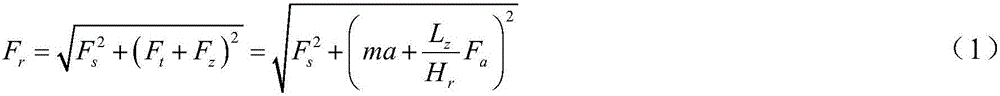

[0017] The loading conditions of train axlebox bearings are relatively complicated, and are affected by many aspects such as axlebox springs, wheel shafts, and rotating arms, but they can basically be divided into two categories, namely radial loads and axial loads. Radial loads can be divided into sprung loads, axle loads, arm effect loads, centrifugal effect loads, and traction brake loads. Axial loads are mainly axle loads and arm loads. In fact, the axial spring load and the arm load play a decisive role in these loads. Therefore, if the spring load and the arm load at the position of the axle box can be accurately obtained, then the diameter acting on the bearing can be determined more accurately. load and axial load.

[0018] Specifically in the present invention, the test prediction method of train axle box bearing life comprises the steps:

[0019] Step (1), arrange the sensor on the spring and the rotating arm of the axle box of the test vehicle (this is a convention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com