Step type and spiral reverse rotation bottom sill type combined energy dissipation facility and energy dissipation method

A reverse-rotating, stepped technology, applied in water conservancy projects, marine engineering, coastline protection, etc., can solve the problems of structural cavitation damage and weakened energy dissipation efficiency, and achieve the process of increasing rotation and hedging, and enhance the energy dissipation effect. , the effect of increasing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

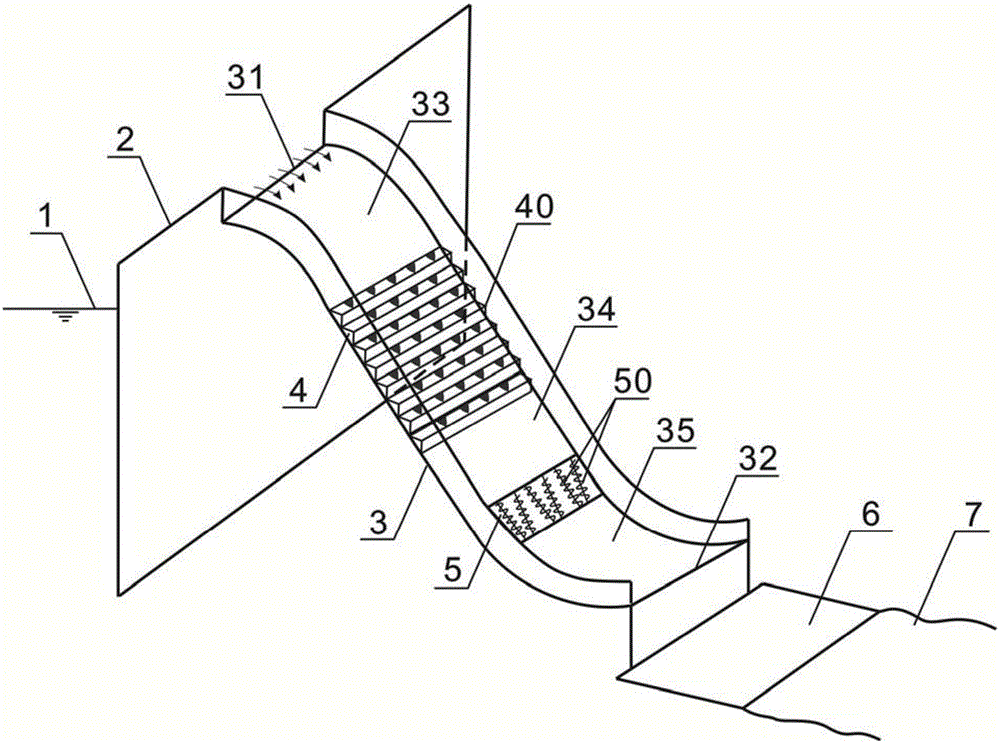

[0035] Such as Figure 1-Figure 5 As shown, the ladder type-helical counter-rotating sill type joint energy dissipation facility structure of the present invention, the main body includes an overflow weir 3, a ladder structure 4, a spiral impeller structure 5 and a water cushion pond 6, the overflow weir 3 and the dam 2 are connected as one, and the water cushion pond 6 is connected with the downstream river course 7.

[0036] Such as figure 1 As shown, the overflow weir 3 is composed of an arc section 33, a straight line section 34, and an anti-arc section 35. The water inlet 31 of the overflow weir 3 is connected with the upstream reservoir 1, and the water outlet 32 of the overflow weir 3 is located in the water pad Above pond 6.

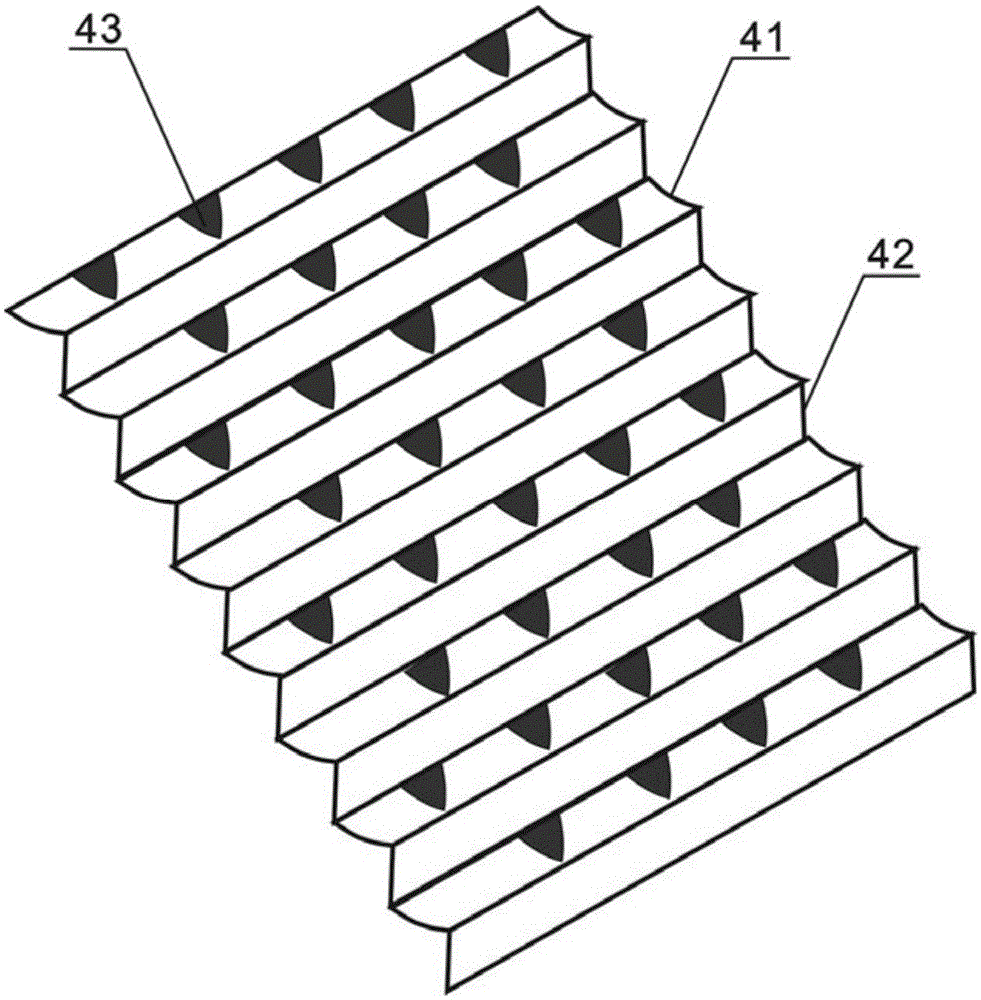

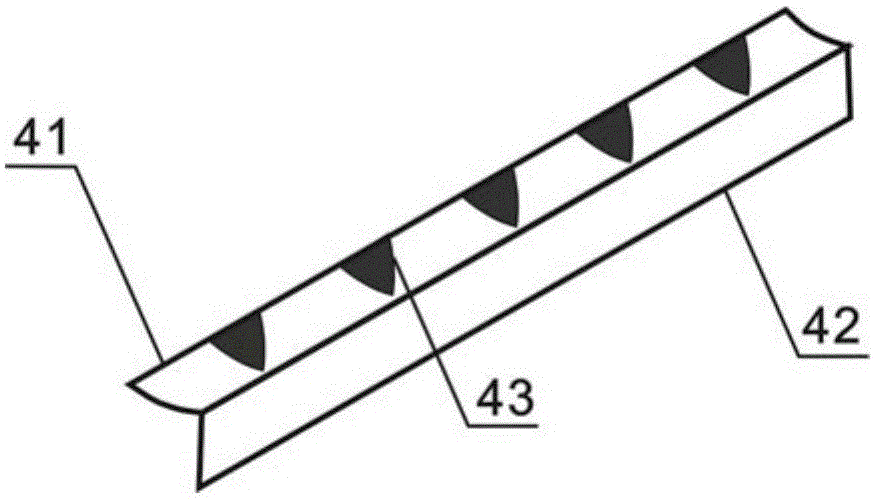

[0037] Such as figure 1 , figure 2 and image 3As shown, the ladder structure 4 is composed of eight ladder units 40, and the ladder structure 4 is fixed on the straight section 34 of the overflow weir 3. Each ladder unit 40 is composed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com